. A complete Parts List is available at www.MillerWelds.com

OM-1327 Page 43

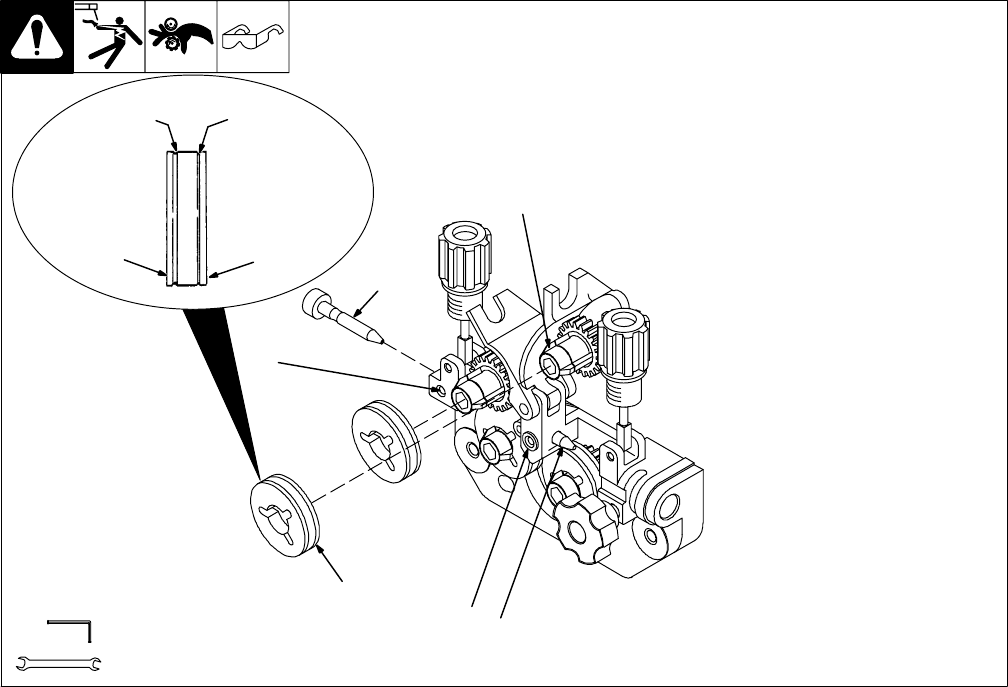

6-4. Changing Drive Roll and Wire Inlet Guide

1 Securing Screw

2 Inlet Wire Guide

Loosen screw. Slide tip as close to

drive rolls as possible without

touching. Tighten screw.

3 Intermediate Guide

4 Drive Roll

. The drive assembly comes

equipped with factory

installed .035/.045 combina-

tion drive rolls. Be sure that all

4 drive rolls are installed cor-

rectly.

Combination drive rolls consist of

two different sized grooves. The

stamped markings on the end sur-

face of the drive roll refers to the

groove on the opposite side of the

drive roll. The groove closest to the

carrier gear is the groove for the

wire size viewed on the end surface

of the drive roll.

Install correct drive roll for wire size

and type.

. U-Grooved drive rolls are re-

quired for feeding aluminum

wire.

5 Drive Roll Securing Nut

Turn nut one click to secure drive

roll.

1

2

4

5

Tools Needed:

5/64 in

7/16 in

802 520-B

1

3

Stamped

.035

Stamped

.045

.045 Groove

.035 Groove