. A complete Parts List is available at www.MillerWelds.com

OM-1327 Page 30

SECTION 5 − PROGRAMMING

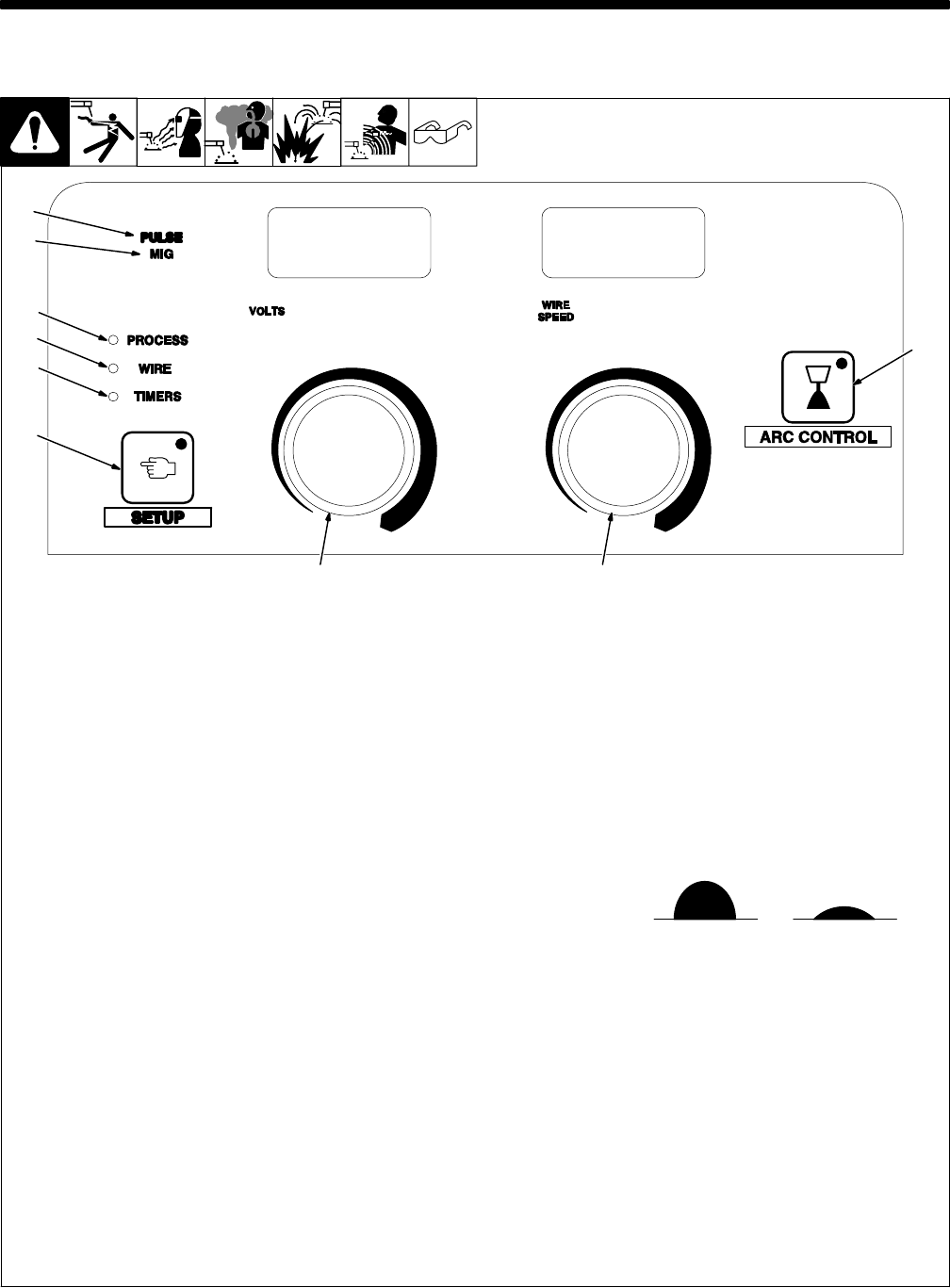

5-1. MIG Welding Mode

When the MIG light (2) is illuminated, the

unit is in MIG Welding mode.

SETUP

To enter MIG welding mode, depress the

SETUP (6) button once to go to GUN

selection. Rotate the right knob (9) to select

the gun being used. Select MIG for standard

MIG gun, or select XR-A, EDGE, PYTH alpr

for push pull guns, or SPL for spoolgun.

Depress SETUP (6) a second time to

illuminate the PROCESS (3) light. Rotate

right knob (9) until MIG is displayed (for MIG

only units NOT USED will be displayed).

Depress SETUP (6) button again to

illuminate the WIRE (4) light. This menu is

not used in MIG Welding mode.

Depress SETUP (6) button again to

illuminate TIMERS (5) light. For description

of the TIMERS, refer to TIMERS menu

(see Section 5-3)

If crater fill function menus are enabled,

TIMERS light will stay on to allow for adjust-

ment of crater parameters and timers (see

Section 5-6).

Depress SETUP (6) button again to exit

menus and enter MIG welding mode.

OPERATION

Adjust welding Voltage with left knob (8)

and Wire Feed Speed with right knob (9).

Refer to MIG welding chart for proper

Voltage and Wire Feed Speed setting in

reference to material type, material

thickness, wire, and gas (see Section 4-9).

ARC CONTROL

MIG welding mode: Depress ARC

CONTROL (7) button to enter Arc control

menu and INDU will appear on the left

display and the corresponding setting will

appear on the right display. Adjust right

knob (9) to adjust inductance setting. In

MIG welding mode the Arc control is an

inductance control from 0-99. Refer to MIG

welding chart for suggested Inductance

setting for the wire and gas types being

used (see Section 4-9). Changing the

inductance will change the fluidity of the

puddle.

Low Inductance High Inductance

Weld Bead Weld Bead

(0 setting) 99 setting

Ref. 213 935-A

1

7

98

2

3

4

5

6