OM-224 043 Page 16

4-2. Switching On the Unit and Recalling Factory Parameters

. Write down any parameters

that need to be restored before

performing this procedure.

1 Power Switch

Use power switch to turn unit On.

When ITW appears on D1 and D2,

press P3 and P8 simultaneously.

When MEMO CLEAR appears on

D1 and D2, release P3 and P8.

Wait until DONE appears on D1,

and turn unit Off.

The next time unit is turned On, all

parameters will return factory de-

fault settings.

1

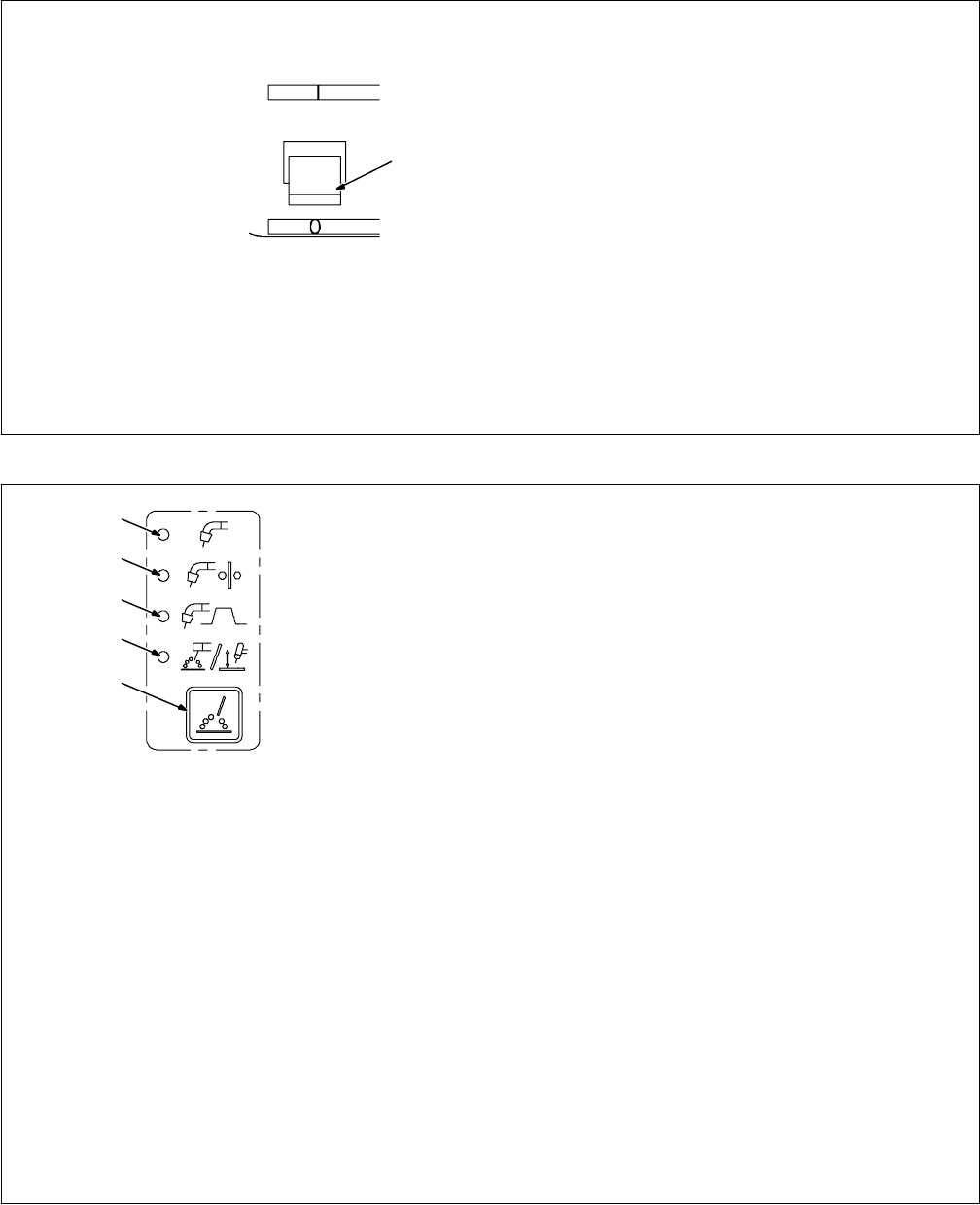

4-3. Welding Process Selection

L1

L2

L3

L4

P3

L1 LED

L2 LED

L3 LED

L4 LED

P3 Push Button

Press P3 until desired process LED illumi-

nates.

Values and parameters that appear on D1

and D2 are either factory default settings or

last settings entered for the selected pro-

cess.

L1 selection is Manual MIG welding.

D1 value is welding voltage, default is

18.5V (range is 10 V to 50 V).

D2 value is wire feed speed, default is 5.0

m/min (range is 1 m/min to 20 m/min). See

Section 4-10.

L2 selection is Synergic MIG welding (non-

pulsed).

D1 value is trim, default is 0.0 T (range is

−5.0 T to 5.0 T).

D2 value is wire feed speed (from minimum

to maximum value according to welding

curve selection).

. When L2 is flashing, material transfer

in the arc is by large droplets (globular

transfer) and produces considerable

spatter. This is the result of selecting a

specific material, wire, gas, voltage,

and current combination. To avoid this

situation, Synergic Pulsed MIG weld-

ing with the same parameter combina-

tion is recommended. When L2 is On

continuously (not flashing), material

transfer in the arc is either short circuit

(Short Arc) or by small droplets (Spray

Transfer). Both MIG processes pro-

vide a stable arc and minimum spatter.

L3 selection is Synergic Pulsed MIG weld-

ing.

D1 value is trim, default is 0.0 T (range is

−5.0 T to 5.0 T).

D2 value is wire feed speed (from minimum

to maximum value according to welding

curve selection).

L4 selection is TIG welding or STICK weld-

ing.

If selected process is TIG:

D1 displays TIG, and D2 value is welding

current, default is 220 A (range is 10 A to

400 A).

If selected process is STICK:

D1 initially displays STICK and changes to

open circuit voltage at approximately 85 V,

and D2 value is welding current, default is

220 A (range is 10 A to 400 A).