OM-224 043 Page 22

4-13. Selecting Synergic Pulsed MIG Welding

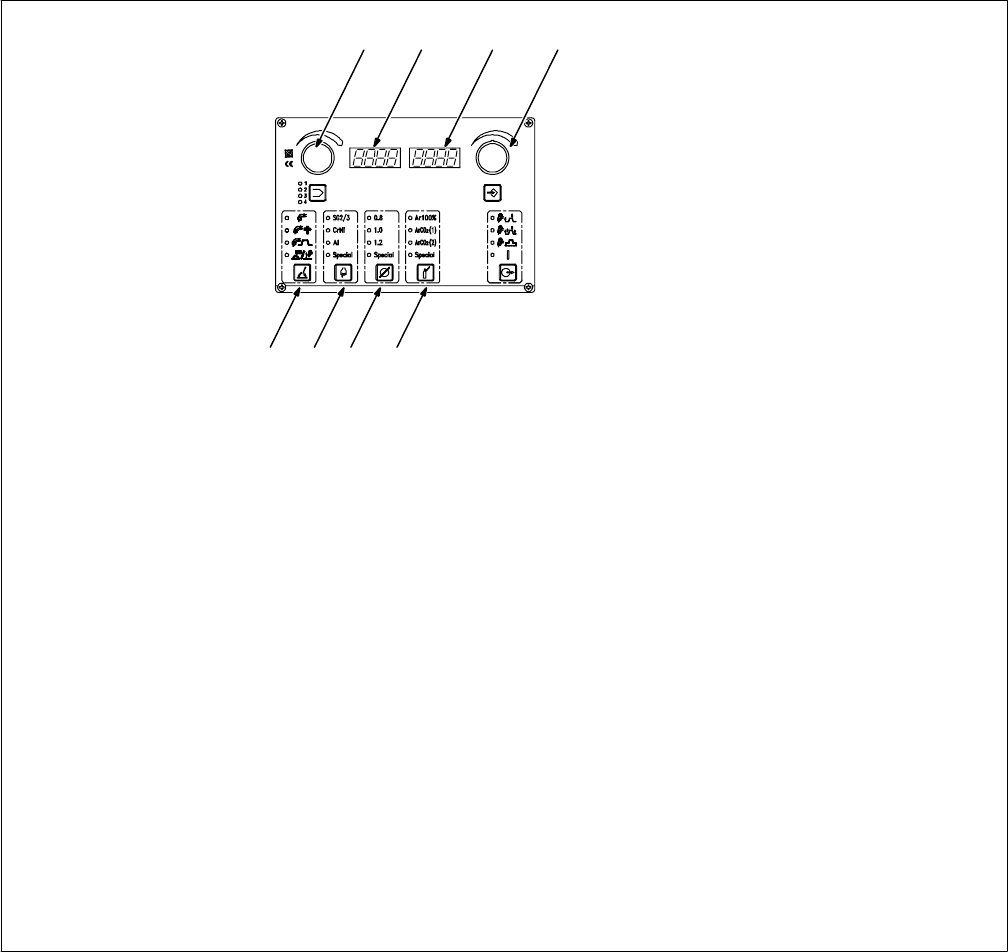

P3 P6

E1 D1 D2 E2

P4 P5

Set Synergic Pulsed MIG welding process

using P3 push button.

Synergic Pulsed MIG welding is a high

quality welding process that produces very

little spatter. This process works well on

thin metals such as stainless steel and alu-

minum.

In Synergic Pulsed MIG mode, the opera-

tor may need to adjust welding data (wire

type, wire diameter, and gas type) and only

one weld parameter. Generally, wire feed

speed is adjusted and the synergic pro-

cess automatically sets appropriate weld

voltage. Synergic welding also sets many

secondary welding parameters automati-

cally for improved weld quality.

During Setting:

D1 value is the default voltage setting

(range is defined by wire type, wire diame-

ter and gas type selection).

D2 value is the default current setting

(range is defined by wire type, wire diame-

ter and gas type selection).

During Synergic MIG Welding:

D1 value is Measured Welding Voltage in

Volts.

D2 Value is Measured Welding Amperage

in Amperes.

Select wire type using P4 push button.

Select wire diameter using P5 push button.

Select trigger mode using P6 push button.

See wire feeder manual for all the remain-

ing Synergic MIG settings.

Setting Cooler Status (see Section 4-11)

Setting Synergic Double Pulsed MIG

Welding

Some metals weld better using the Synerg-

ic Pulsed Welding process due to the

unique pulsing of the welding arc. Heat

generated in the workpiece is generally

lower and the arc characteristics produce

a better weld bead appearance especially

on aluminum. The Synergic Double Pulsed

MIG process allows control all parameters

to produce high quality welds on aluminum.

. Incorrect settings in Synergic Double

Pulsed Welding process can result in

a program with undesirable weld char-

acteristics. Setup should only be used

by operators familiar with various

welding processes and parameters. In

some cases, standard Synergic

Pulsed MIG welding can produce bet-

ter welds.

Use E1 to change D1 to DP.

D2 value is default setting of OFF.

Use E2 to change D2 value to ON. This set-

ting will enable or disable Double Pulse in

Synergic Pulsed MIG welding.

. On power source, only Double pulse

enabling and disabling is possible. All

the remaining Double Pulse settings

are made on teh wire feeder (see Wire

Feeder manual). From the wire feeder

it is possible to recall Synergic MIG,

Synergic Pulsed MIG and Synergic

Double Pulsed MIG programs (see

Wire Feeder manuals).