63

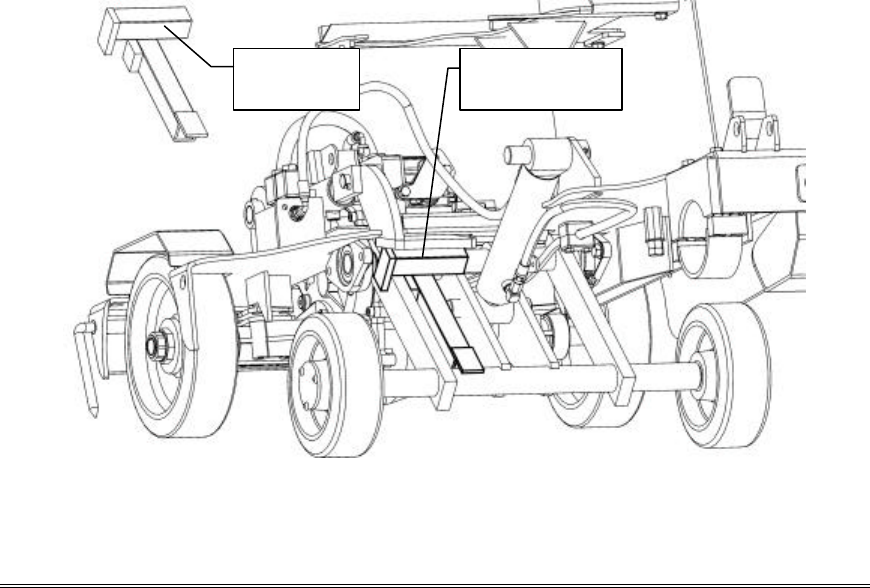

Bleeding the Depth Stop Cylinder

After changing the hydraulic system oil, or after disturbing the Depth Stop

Cylinder plumbing, air may become trapped in the system and cause the Depth

Stop Cylinder to work improperly. To remedy the situation, the Depth Stop

Cylinder must be bled to remove trapped air. This procedure requires the use of

the Depth Stop Block tool (P/N 584042)..

1. Open the Depth Stop Valve.

2. Fully raise the saw.

3. Place the Depth Stop Block between the Depth Stop Plate and the Front

Axle.

4. Fully lower the saw.

• Verify that the Depth Stop Cylinder has fully collapsed.

5. With the Depth Stop Valve still open, and the engine running:

• At the rear of the cylinder use a 1/8” diameter hose on the bleeder nipple.

Use the length of hose to direct the flow of oil into a suitable receptacle.

• Open the bleeder valve at the rear of the cylinder and allow the oil to flow

until no air is detected in the fluid. Close the bleeder valve.

• Tighten the hose connection.

• Dispose of the waste oil in an environmentally-friendly manner.

6. Remove the Depth Stop Block and test the operation of the Depth Stop.

7. Re-fill the Reservoir Fill bottle at the rear of the Fuel Tank.

Fig. 47 — Bleeding the Depth Stop Cylinder

Depth Stop

Block tool

Depth Stop Block

tool in place