Installation & Programming Manual FX & VFX “E” Series Inverte r/Charge r Sy ste m Copyright 2003 OutBack Power Systems, Inc.

19009 62

nd

Ave NE, Arlington WA 98223 USA

Page 6 Rev 7.0 07/02/04 Tel 360 435 6030 Fax 360 435 6019

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This manual contains important instructions for the OutBack FX “Export” (or “E”) series inverter/charger system with the software which

allows parallel and 3-phase stacking of multiple units for higher power and/or higher voltage systems.

1 All of the AC field wiring terminals are to be torqued to 30 inch-pounds (equivalent to 2.5 foot-pounds or 3.4 Nm).

Wiring to these terminals must meet requirements of the local electric code. The terminals will accept up to 6AWG (13.3mm

2

). Use

copper conductors only with insulation rated for 75˚ C. See the AC WIRING CONNECTIONS section of this manual for more

information.

2 Torque the DC connections to 60 inch-pounds (equivalent to 5 foot-pounds or 6.8 Nm). Cables to these terminals must

use a crimp on type ring terminal or compression type lug. Cable must meet the requirements of the National Electrical Code. Use of

large gauge cables {2/0 AWG (68mm

2

) or 4/0 AWG (107mm

2

)} or larger is advisable to reduce losses and ensure high performance of

the FX. Cables of too small a gauge can result in poor performance and even damage the FX. Keep the cables together as much as

possible and ensure that both cables pass through the same knockout and conduit fittings to allow the magnetic fields of the cables to

cancel.

3 For equipment grounding hook up, see wiring instructions in this manual. This product is intended to be installed as part of a

permanently grounded electrical system.

4 AC overcurrent protection for all connections must be provided by others as part of the installation.

5 DC battery circuit overcurrent protection must be provided by others as part of the installation.

OutBack offers 100, 175 and 250 amp DC breaker (part number OBDC-XXX) which can be used with the FX. OutBack also offers a

stud mounted fuse which can be connected directly to the positive DC terminal of the FX – it is available in 100, 175 and 250 amp

sizes (part number SMF-XXX) The Stud mounted fuses require a 10mm hole in the battery terminal lug. US lugs are typically 3/8”

diameter. Light filing may be required to insure proper fit of the nut shoulder into the lug hole.

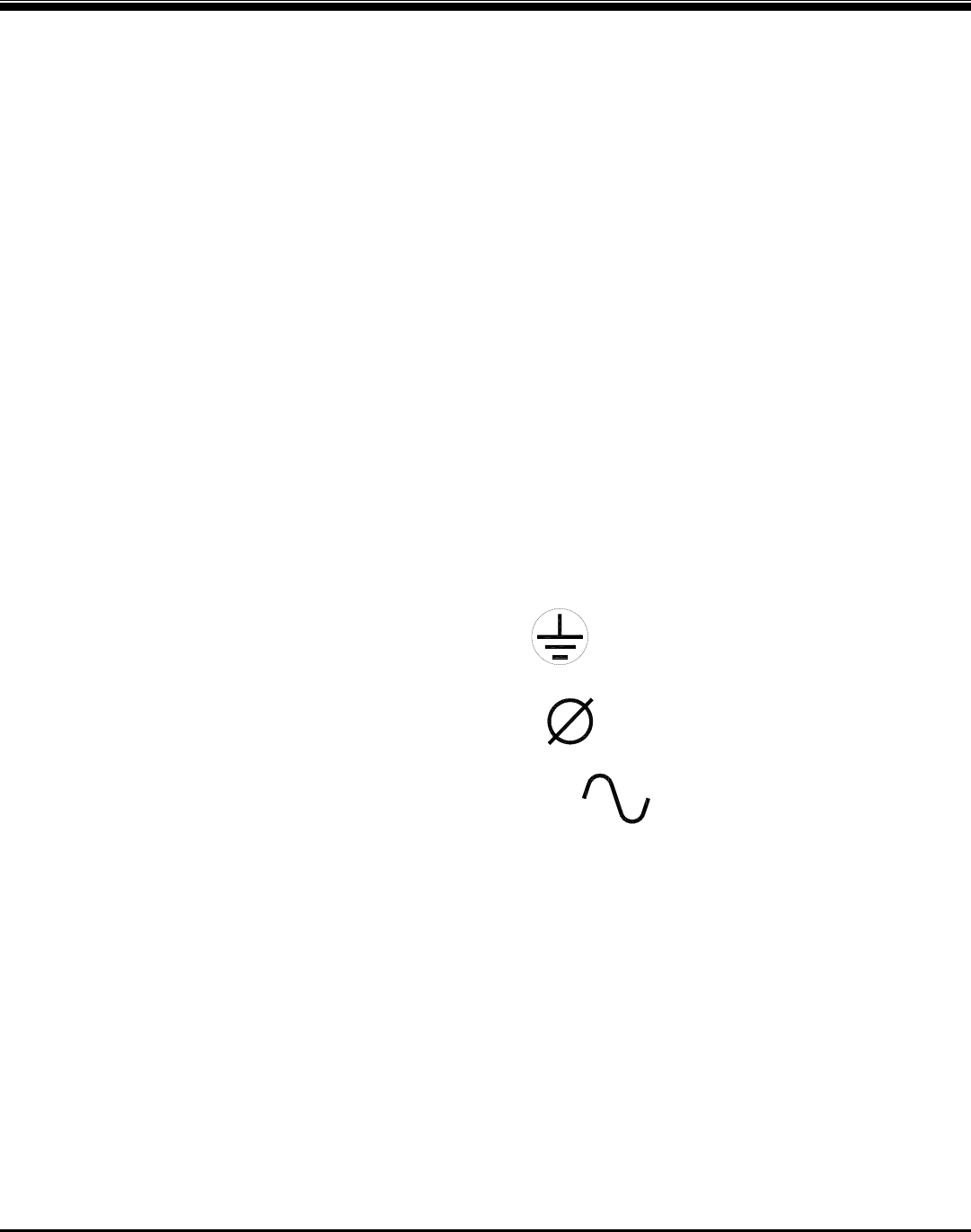

6 The equipment ground on the inverter is marked with this symbol:

7 This inverter has a single phase output. It is marked with this symbol:

8 This inverter puts out a sine wave waveform. It is marked with this symbol:

9 CAUTION: To reduce the risk of fire, connect only to a circuit provided with 30 amp maximum branch-circuit overcurrent

protection.