14

Figure 14

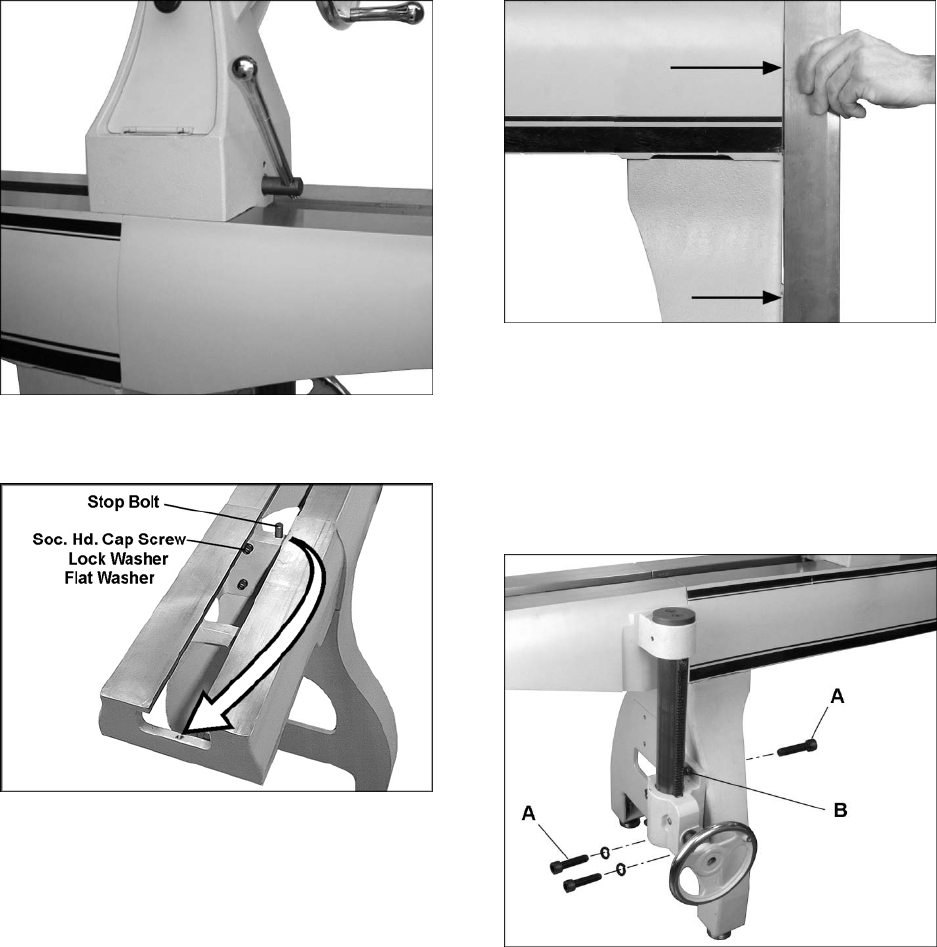

7. Unscrew stop bolt from lathe bed (Figure 15),

and insert it into hole at end of bed extension.

Figure 15

7.10.2 20” Bed Extension Kit (6294900)

Tools required:

8mm hex key

10mm hex key

Straight Edge

1. Slide tailstock away from edge of bed.

2. Place a straight edge against bed and raised

area of leg (Figure 16). These two areas

should be flush. If they are not, support the

lathe (with fork lift, hoist, etc. – USE

CAUTION!) and loosen the screws holding leg

to bed. Nudge leg as needed, then retighten

screws firmly.

3. Install 20-inch bed extension in the same

manner as described in section 7.10.1.

Figure 16

4. Install elevating system (Figure 17) to bed

extension with four 3/8" screws and washers,

and to lathe leg with three 1/2” screws and

washers (A, Figure 17). Note that top screw is

installed from inside the leg and secured with

the nylon nut (B). Refer to exploded view,

section 17.5.1 if clarification is needed.

5. Install handwheel and tighten setscrew.

Figure 17

Remove screws in bed extension to swing away

the bed, or to move bed to lower set of holes. Note:

If heavy loading makes handwheel turning difficult,

a 19mm wrench can be used to turn hexagonal

shaft (Figure 18).

For outboard turning, where headstock is moved to

opposite end of lathe to accommodate large bowl

blanks, you can (1) mount the 20-inch bed

extension to the lower set of holes on the Lathe

frame, and (2) mount an extension post [included

with kit] to the tool rest base. See Figure 19.

For larger outboard work, an outboard turning

stand (# 6294732) is available; see section 13.0,

Optional Accessories.