22

10.0 Operating controls

See Figures 33 and 34.

(H) Vacuum on/off switch with gauge.

(I) On/Off (headstock): Push in to stop lathe; pull

out to start.

(J) Forward/reverse

When turning with face plate

or vacuum chuck, make sure both set screws

on the plate/chuck are tight before reversing

spindle. Failure to comply may allow face

plate/chuck to spin loose from spindle.

(K) Speed control dial: Always start lathe at

lowest speed, with dial rotated all the way

counterclockwise.

NOTE: Do not attempt to alter settings of the

Variable Frequency Drive (A.C. Inverter). Use only

the controls on the front of the headstock. See

section 8.3 for more information.

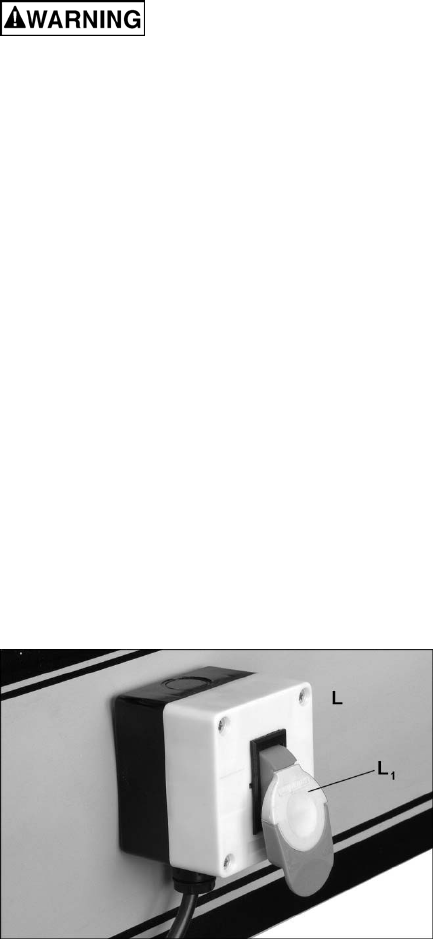

(L) On/off (remote switch): Lift paddle on switch

box to start. Push in to stop. The safety key (L

1

)

can be removed to prevent starting. Safety key

must be reinstalled for lathe to start.

NOTE: The remote switch will not work if the stop

switch on the headstock is engaged. Rotate

clockwise to disengage.

The remote switch box has a magnetic backing

and can be attached to any metallic surface of the

lathe.

If a power outage occurs while operating lathe, the

lathe will not automatically restart once power is

restored. Cycle the on/off switch in order to restart

the machine.

Figure 34

11.0 Operation

The information which follows is general in nature

and not intended to be a complete course in

woodturning. Nothing can replace the knowledge

gained by talking with experienced woodturners or

consulting books or trade magazines. Above all,

simple trial and error will aid in developing

proficiency in the craft.

11.1 Inspection

Before operating the lathe, check that everything is

in proper working order:

1. Level your machine; use the leveling feet to

help reduce vibration.

2. Check bearings; adjust only if endplay exists.

3. Check belt; it should be snug but not overly

tight.

4. Bed ways; keep clean, use steel wool to

remove any rust spots, and apply paste wax to

prevent buildup of rust and finishes.

5. Tool support; use a mill file to remove nicks

and dings.

6. Spindle tapers; should be clean and free of

dust and chips for proper seating of tapers.

7. Tailstock; clean and lubricate quill and locking

device.

8. Lighting; proper lighting is essential to

eliminate shadows and reduce eye strain.

11.2 Turning Tools

If possible, select only quality, high-speed steel

turning tools. High-speed steel tools hold an edge

and last longer than ordinary carbon steel. As one

becomes proficient in turning, a variety of specialty

tools for specific applications can be acquired. The

following tools provide the basics for most

woodturning projects (see Figure 35):

Skews – 1-1/2" and 1" or 1-1/4", used to make

finishing cuts and details.

Large Roughing Gouge – 1" to 1-1/4", used to

eliminate waste wood.

Spindle Gouges – 1/4", 3/8", 1/2", used to turn

beads, coves and other details.

Deep Fluted Bowl Gouge – 1/4", 3/8" and 1/2",

used for turning bowls & plates.

Square Scraper (Bedan) – 3/8” or 1/2", used to

create square shoulders.

Large Round Nose (Domed) Scraper – 1-1/2",

used to reduce ridges on interior of bowls, round

edges of bowls, etc.

Parting Tool - 1/8", used for scraping, making a

cut-off, or to set diameters for sizing.