19

9.7 Centers: Installing/removing

1. Disconnect lathe from power source.

2. To install a spur center or live center (a spur

center should first be mounted to your

workpiece; see section 11.4), clean tapered

end of center and inside of headstock taper

spindle, then push center into headstock

spindle.

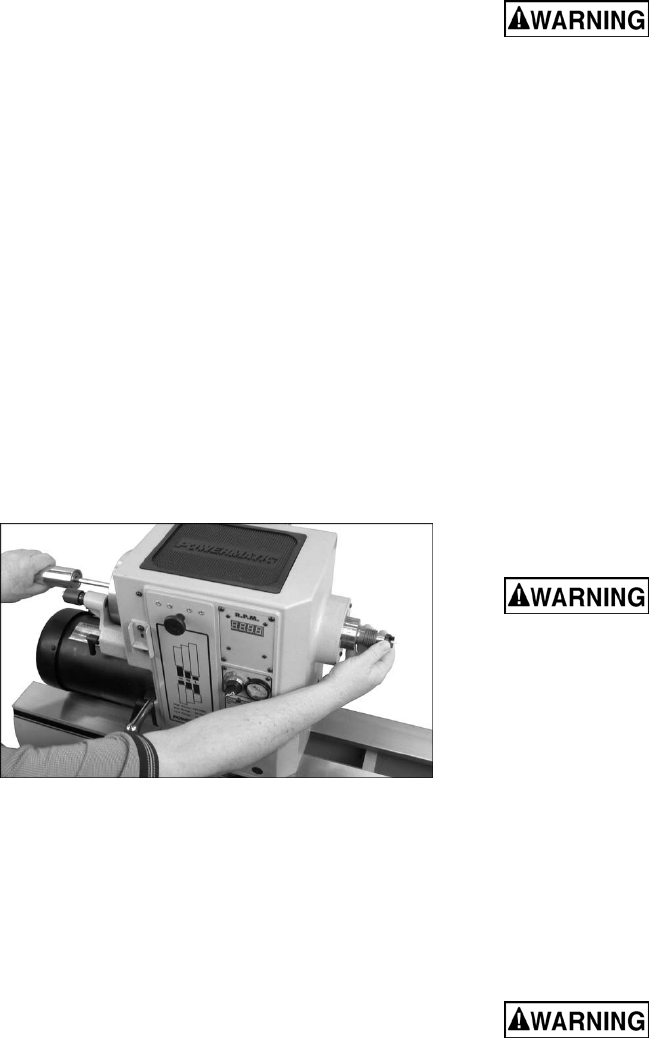

3. To remove a spur center or live center, first

remove workpiece from lathe. Insert knockout

rod (Figure 28) through hole in handwheel and

firmly tap the tapered end of spur center. The

sliding collar on the knockout rod helps give

the necessary impact without having to use a

mallet against the end of the rod.

IMPORTANT: Hold the center by either

placing your thumb and forefinger on outside

diameter of spur center, or wrapping center

with a rag. The center can be damaged if

allowed to fall.

Figure 28

9.8 Spindle lock

1. Push spindle lock button (see G, Figure 33),

and rotate spindle slightly until button goes

entirely into recess. Slide plate down over

button.

2. Rotate spindle by hand until it locks.

3. Slide plate upward to release spindle.

IMPORTANT: Always release spindle lock before

turning on lathe.

9.9 Face plate: Installing/removing

1. Disconnect lathe from power source.

2. Mount face plate to your bowl blank.

3. Lock spindle.

4. Install face plate onto threads of headstock

spindle and rotate clockwise hand-tight. When

lathe is turned on (forward rotation), the

rotational force will snug the face plate even

farther onto the threads.

5. Face plate is now ready for turning.

If at any time you will be

reversing spindle rotation, make sure the two

set screws in the face plate are tight! Failure to

do this may cause the face plate to loosen from

the headstock spindle.

6. To remove face plate, loosen the two set

screws. Engage spindle lock, and turn face

plate counterclockwise with face plate wrench.

9.10 Vacuum chuck:

Installing/removing

1. Disconnect lathe from power source.

2. Lock spindle.

3. Install vacuum chuck onto threads of

headstock spindle and rotate clockwise hand-

tight. When lathe is turned on (forward

rotation), the rotational force will snug the

vacuum chuck even further onto the threads.

4. Make sure vacuum adaptor is inserted into

handwheel, and air supply is connected. Turn

on air system and place workpiece against

vacuum chuck.

If at any time you will be

reversing spindle rotation, make sure the set

screws in the vacuum chuck are tight! Failure

to do this may cause vacuum chuck to loosen

from headstock spindle.

5. To remove vacuum chuck, turn off air supply,

and loosen the two set screws. Engage

spindle lock, and turn vacuum chuck counter-

clockwise with face plate wrench.

9.11 Comparator

The spindle comparator consists of two comparator

centers inserted into the brackets at rear of lathe.

The comparator is used to mount a finished, or

“reference” spindle, from which measurements can

be taken, the measurements being transferred to

the new piece being turned.

Guard must be removed to

use spindle comparator. Use caution and wear

a face mask when turning without guard

installed.

1. Remove guard from bracket and swing lamp

holder away.

2. Install comparator spur center into guard

bracket, by lifting up on plunger and inserting

comparator spur center until its point is about

even with the point of the spur center in the

headstock spindle. See Figure 29. The plunger

in the bracket should engage one of the holes

in the comparator center at this position.