21

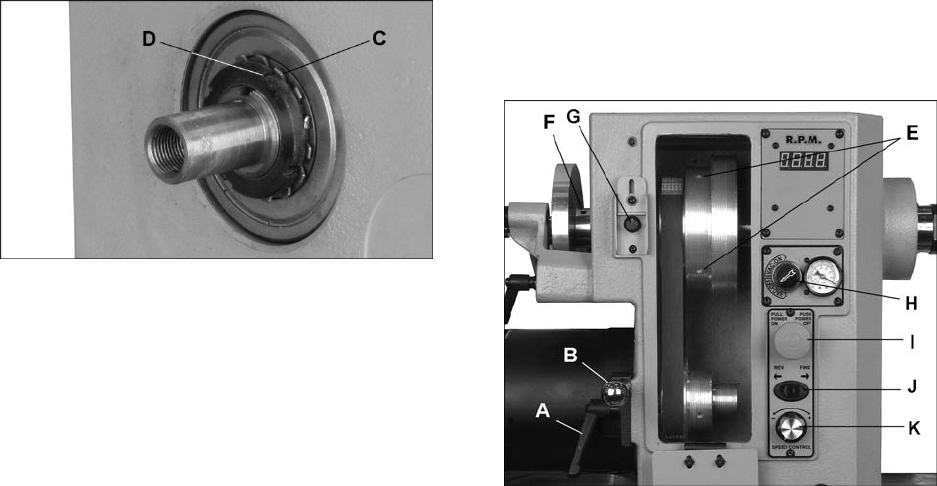

Figure 32

5. The bearing lock nut should be tightened just

enough to remove end play, and spindle

should still rotate freely. Run the lathe for a

time, and check for heat from the spindle

bearings. If the bearings are running hot, the

bearing lock nut is too tight and should be

loosened slightly.

6. After the bearing lock nut (D) has been

properly adjusted, carefully bend back into

place any tabs on the tabbed lock washer (C).

7. Reinstall handwheel and tighten set screws.

9.14 Sheave and belt alignment

The motor and spindle sheaves are aligned with

each other at the factory, but if any service is

performed that affects their alignment it is very

important that they be realigned. To realign them,

loosen the two set screws on the spindle sheave

(E, Figure 33) with a hex key, and slide spindle

sheave into proper position. Re-tighten set screws.

When sheaves and belt are properly aligned, there

should be no unusual pulsing sounds or noise

coming from the belt.

9.15 Sheave/drive belt replacement

Replacing the spindle sheave can be a difficult

procedure; it is recommended that the headstock

be taken to an authorized service center for this.

See Figure 33.

1. Disconnect lathe from power source.

2. Loosen lock handle (A) and lift up handle (B)

to raise motor.

3. Tighten lock handle (A) to hold motor in raised

position. Slip belt off pulleys.

4. Loosen two set screws on handwheel (F) with

a hex key, and pull handwheel off headstock

spindle.

5. Loosen and remove bearing lock nut and

tabbed lock washer (C/D, Figure 32).

6. Slide spindle a short way out of headstock, just

enough to remove sheave or belt.

NOTE: You may have to tap the end of the

spindle with a wood block to move it. (Never

use a steel face hammer directly against the

spindle.)

Figure 33

7. If replacing spindle sheave, loosen two set

screws (E, Figure 33), and slide sheave off

spindle.

8. Install new spindle sheave, loosely securing

the two set screws. Make sure the sheave is

oriented properly.

9. Slide spindle back into place, install tabbed

lock washer, and bearing lock nut (C/D, Figure

32). Check for any spindle play at this point

(See section 9.13, “Checking Spindle Play”).

10. Reinstall handwheel and tighten set screws (F,

Figure 33).

11. Align new sheave (see section 9.14, “Sheave

and Belt Alignment”) then tighten two set

screws (E, Figure 33) securely on sheave.

12. Loosen lock handle and allow motor to lower.

Do not overtension; a very light pressure on

the tension handle is adequate to prevent belt

slippage.

13. Retighten lock handle.