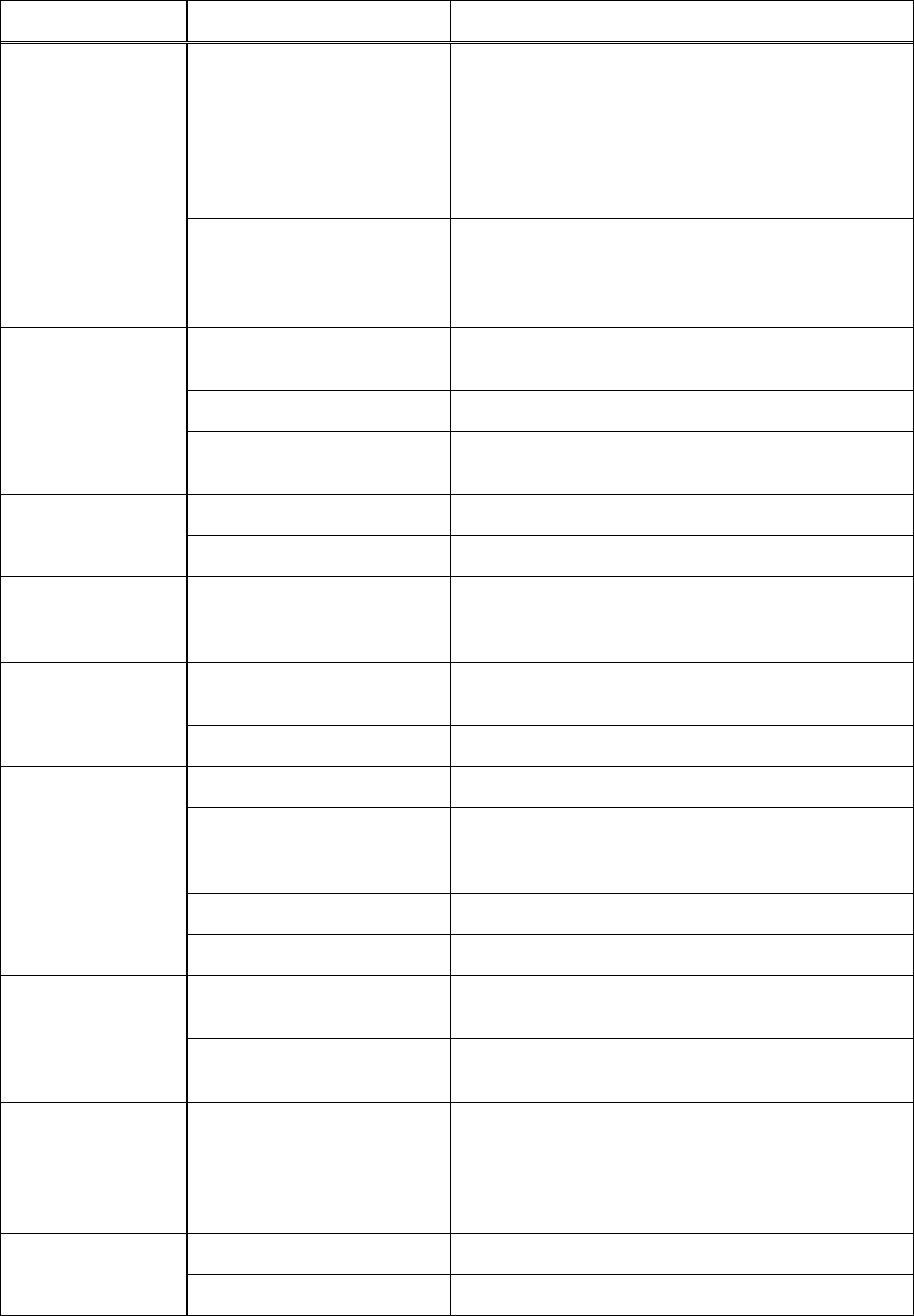

17

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breakers or

blows fuses.

Miswiring of the unit.

Check to make certain all electrical connections

are correct and properly tight. The electrical

connections other than the motor are

preassembled and tested at the factory. Therefore,

the motor connections should be checked as the

highest probability for error. If problems persist,

double check the factory wiring.

On/off switch failure.

If the on/off switch is suspect, you have two

options: Have a qualified electrician test the switch

for function, or purchase a new on/off switch and

establish if that was the problem on changeout.

Sanding belt won’t

come up to speed.

Extension cord too light or

too long.

Use adequate size extension cord.

Low (incoming) voltage. Contact qualified electrician.

Excessive bite, or feed

pressure too great.

Allow sanding belt to cut freely, do not force.

Belt won’t track. Drum is worn. Replace drum.

Belt is stretched unevenly. Replace belt.

Belt slips or stalls

on application of

pressure.

Sanding belt tension not

adequate.

Make sure lever is down all the way (page 13).

Excessive sanding

belt replacement.

Too much pressure being

used during cuts.

Reduce pressure.

Not using full width of belt. Stroke across the belt using full width.

Machine vibrates

excessively.

Improper motor mounting. Check and adjust mounting.

Spring on tension

mechanism is fatigued or

broken.

Replace with new spring.

Drum is loose. Tighten cap screw in motor (page 23, #39).

Bad or broken sanding belt. Replace sanding belt.

Sanding marks on

workpiece.

Sanding belt too coarse for

required finish.

Use proper grit. Coarser grits for stock removal,

and finer grits for finish work.

Workpiece sanded across

grain.

When surface sanding, use very fine sanding belt

then finish by hand, working in direction of grain.

Sanding grains

quickly rub off belt.

Sanding belt has lost its

original properties.

Do not store sanding belts in extremely dry or high-

temperature areas. Do not fold sanding belts.

Sanding belt

becomes glazed.

Sanding painted surface. Use open-end grain/flint belt.

Wood is wet or gummy. No cure. Use different stock.