18

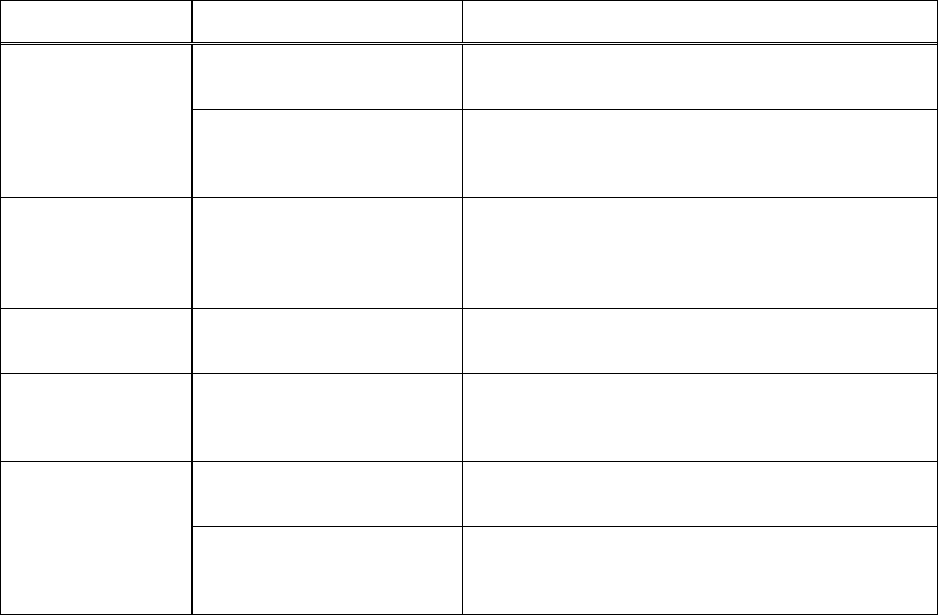

Trouble Probable Cause Remedy

Work burns. Wrong sanding belt

surface.

Use coarser grit for stock removal.

Feed pressure too great. Never force workpiece into steel platen. Use just

enough pressure, and let the sanding belt do the

work.

Sanding belt

burns, or clogs

quickly on

thickness sanding.

Biting too deep. Adjust for slight sanding action and make repeated

passes.

Workpiece pulled

from hand.

No support for workpiece. Use miter gauge on table.

Sanding belt has

broken at the joint.

Belt running in wrong

direction.

Orient direction of arrows printed on sanding belt to

match rotation of drums. Sanding belt should move

left to right as viewed from front of machine.

Sanded edge is

not square.

Result of freehand sanding. Keep workpiece flat on table at all times when a

square edge is desired. Use miter gauge.

Table misaligned. Check table alignment to steel platen with a square

or machinist’s protractor. It should be 90 degrees.

Adjust table angle if necessary (page 12).