17

9.4.3 Extension plate

The extension plate (D, Figure 17) can be adjusted

by sliding to the right or left or removed entirely.

To adjust, loosen two lock handles (E), slide the

extension plate and retighten lock handles. Make

sure end of extension plate is not in blade path.

NOTE: The lock handles (E) are adjustable. Pull

out on handle, rotate it to different position, then

release, making sure it seats itself upon the pin.

To remove extension plate, slide it completely off

and remove lock handles (E) and mounting

hardware.

9.4.4 Calibration

1. Place miter gauge into one of the slots on the

table.

2. Set miter gauge at 90º to blade (0º setting on

the scale) by loosening lock handle (A), then

pulling out spring-loaded knob (C) and turning

body (B) until 0º is indicated on scale.

3. Measure accuracy of miter gauge against slot

with a combination square.

If adjustment is needed:

4. Adjust body (B) until it is square (90º) to miter

slot.

5. Tighten lock handle (A).

6. Verify that scale indicator (G) reads 0º. If

further adjustment is needed:

7. Loosen screw (F) and adjust indicator (G) until

it reads 0º.

8. Tighten screw (F).

9. If the above procedure does not satisfactorily

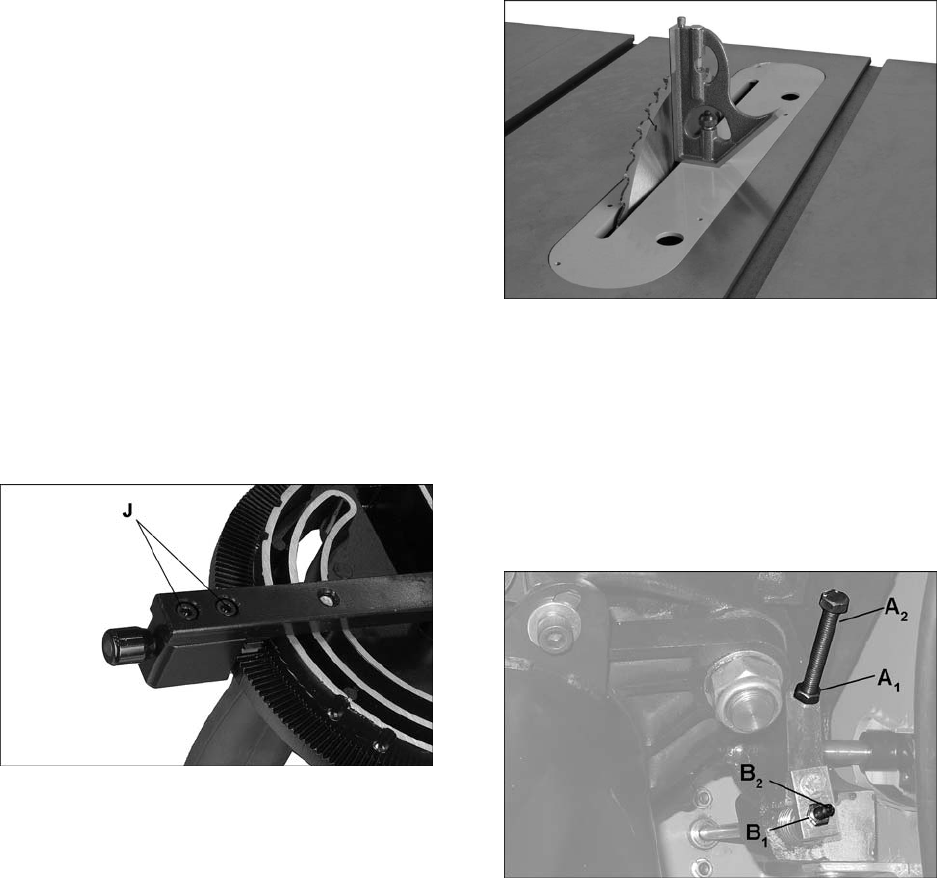

align the miter gauge, loosen two screws (J,

Figure 18) beneath mounting block and shift

block as needed. Retighten screws when

finished.

Figure 18

NOTE: The bar of the miter gauge has two slots

with set screws (H, Figure 17). Adjust these set

screws (4mm hex key) to eliminate any play

between bar and miter slot.

9.5 Blade tilt stop adjustment

The stops for 90°, 45° blade tilt, and elevation

settings have all been factory set, and should

require no immediate adjustment. The settings

should be confirmed by the operator, however, and

especially if cuts become inaccurate. Both tilt stops

are located inside cabinet in front of the motor.

9.5.1 Tilt stop 90°

1. Disconnect machine from power source.

2. Make sure table insert has been leveled with

table surface. See section 7.11.

3. Raise blade all the way, and place a 90°

square on the table and against blade (Figure

19). Make sure that a blade tooth does not

obstruct the actual reading.

Figure 19

4. Tilt blade with handwheel until square and

blade are flush.

5. If adjustment is required, loosen nut (A

1

,

Figure 20) on 90° stop screw (A

2

) with a 12mm

wrench, and turn screw to proper height. Verify

setting and retighten nut.

6. Check pointer position (Figure 21). If needed,

loosen screw and adjust pointer to zero.

Retighten screw.

Figure 20