28

14.0 Troubleshooting the PM1000 Cabinet Saw

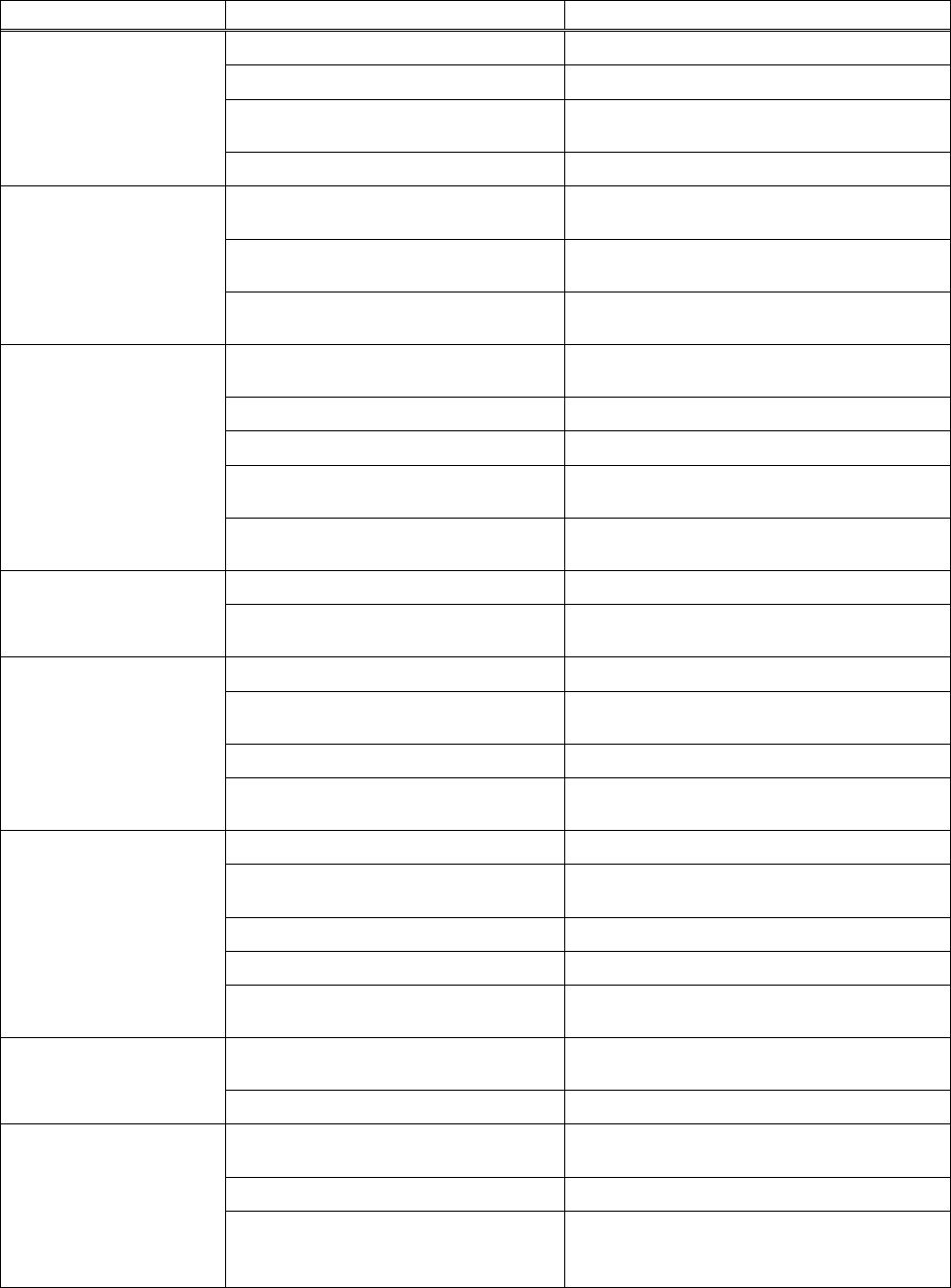

Table 2

Symptom Probable Cause Remedy

Saw will not start.

No incoming power. Check plug connection.

Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Inspect all lead connections on motor for

loose or open connections.

Cord damaged. Replace cord.

Saw will not start: fuse

blows or breaker trips.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

and shorted wires.

Short circuit in motor or loose

connections.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Incorrect fuses or circuit breakers in

power line.

Install correct fuses or circuit breakers.

Motor starts slowly or

fails to reach full speed.

Low voltage.

Request voltage check from power company

and correct low voltage condition.

Power line overloaded. Correct overload condition.

Undersized wires in supply system. Increase supply wire size.

Centrifugal switch not operating.

Replace centrifugal switch (qualified

personnel only).

Motor malfunction.

Have motor checked by a qualified

inspector. Repair or replace.

Motor overheats. Motor overloaded. Reduce load on motor.

Improper cooling of motor; lack of air

circulation.

Clean sawdust from fan and duct areas of

motor.

Motor stalls, resulting in

blown fuses or tripped

breaker.

Motor overloaded. Reduce load on motor.

Short circuit in motor or loose

connections.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Low voltage. Correct low voltage conditions.

Incorrect fuses or circuit breakers in

power line.

Install correct fuses or circuit breakers.

Motor stalls or workpiece

binds or burns.

Excessive feed. Reduce feed.

Dull or incorrect blade.

Replace blade; use proper type of blade for

cut needed.

Miter slot misaligned. Realign table to blade.

Fence misaligned. Realign fence (see Accu-Fence manual).

Motor malfunction.

Have motor checked by a qualified

inspector. Repair or replace.

Machine slows or stalls

when operating.

A

pplying too much pressure to

workpiece.

Feed workpiece more slowly.

Poly-v drive belt is loose. Tighten belt.

Loud, repetitive noise

coming from machine.

Pulley setscrews or keys are missing

or loose.

Inspect keys and setscrews. Replace or

tighten if necessary.

Motor fan is hitting the cover. Tighten fan or shim cover.

V-belt is defective.

Replace V-belt.