21

accidents. Never use a cracked saw blade.

The use of a sharp, well maintained, and

correct cutting tool for the operation will

help avoid injuries.

Support the work properly and hold it firmly

against gauge or fence. Use a push stick

or push block when ripping short, narrow

(6" width or less), or thin work. Use a push

block or miter gauge hold-down when

dadoing or molding.

Never use the fence as a length stop when

crosscutting. Do not hold or touch the free

end or cutoff section of a workpiece. On

through-sawing operations, the cutoff

section must NOT be confined.

Always keep your hands out of line of the

saw blade and never reach back of the

cutting blade with either hand to hold the

workpiece.

Bevel ripping cuts should always be made

with the fence on the right side of saw

blade so that the blade tilts away from the

fence and minimizes possibility of the work

binding and the resulting kickback.

10.2 Rip sawing

Ripping is feeding the workpiece with the grain into

the saw blade using the fence or other positioning

device as a guide to ensure desired width of cut

(Figure 31).

Before starting a ripping cut,

verify that fence is clamped securely and

aligned properly.

Never rip freehand or use miter gauge in

combination with the fence.

Never rip workpieces shorter than the saw

blade diameter.

Never reach behind the blade with either

hand to hold down or remove the cutoff

piece with the saw blade rotating.

Figure 31

Always use blade guard, splitter/riving knife and

anti-kickback pawls. Make sure splitter/riving knife

is properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the blade

and kickbacks can occur.

Note: A warning decal is affixed to the guard to

remind the operator of some basic safety

procedures.

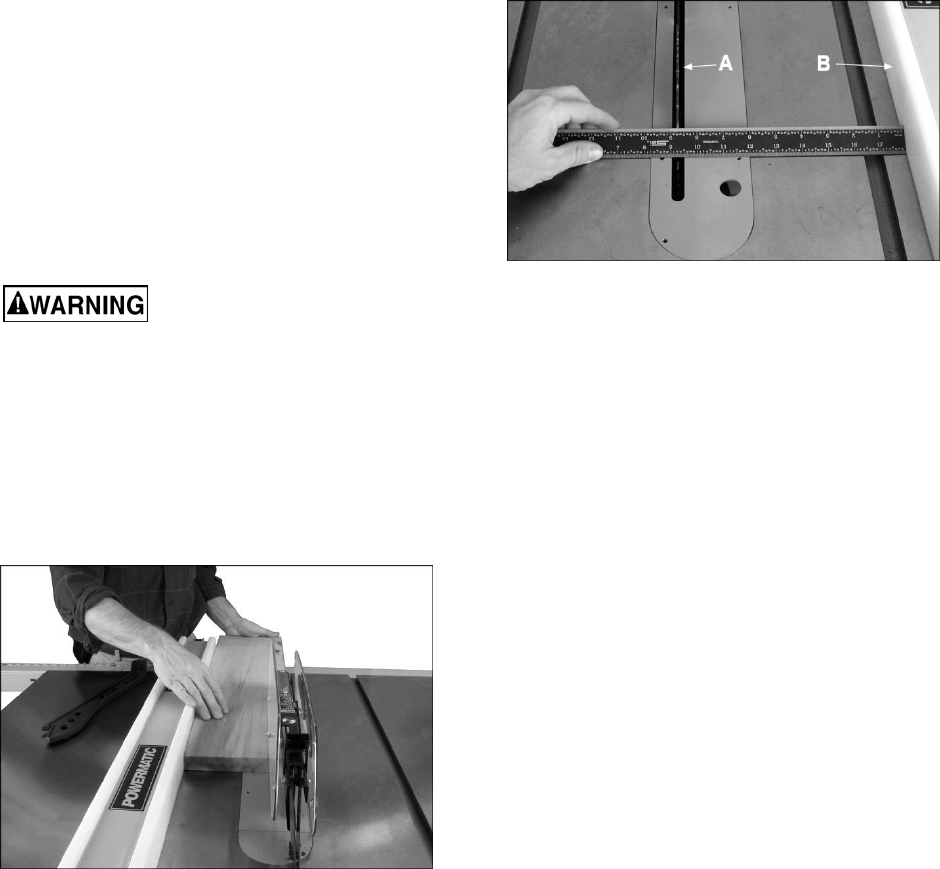

The rip fence (A, Figure 32) should be set for the

width of the cut by using the scale on the front rail,

or by measuring the distance between blade (A)

and fence (B). Stand out of line with saw blade and

workpiece to avoid sawdust and splinters coming

off the blade or a potential kickback.

If the work piece does not have a straight edge,

nail an auxiliary straight edged board on it to

provide one against the fence. To cut properly, the

board must make good contact with the table. Do

not attempt to cut warped boards.

Figure 32

In ripping, use one hand to hold the board down

against the fence or fixture, and the other to push it

into the blade between blade and fence. If

workpiece is narrower than 6" or shorter than 12",

use a push stick or push block to push it through

between fence and blade (Figure 33). Never push

in a location such that the pushing hand is in line

with the blade. Move the hand serving as a hold-

down a safe distance from blade as cut nears

completion.

For very narrow ripping where a push stick cannot

be used, use a push block or auxiliary fence.

Always push the workpiece completely past the

blade at the end of a cut to minimize the possibility

of a kickback.