19

1. Disconnect Lathe from power source.

2. Loosen the pivot lock handle (A, Figure 25)

and lift up the tension handle (B, Figure 25)

to raise the motor.

3. Tighten the pivot lock handle (A, Figure 25)

to hold the motor in the raised position. Slip

the belt off the pulleys.

4. Loosen the two set screws on the

handwheel (A, Figure 26) with a hex

wrench, and pull the handwheel off the

headstock spindle.

5. Loosen and remove the bearing lock nut (B,

Figure 26) and tabbed lock washer (C,

Figure 26).

6. Slide the spindle a little way out of the

headstock, just enough to remove sheave or

belt.

NOTE: You may have to tap the end of the

spindle with a wood block to move it. (Do

NOT use a steel face hammer directly

against the spindle.)

7. If replacing the spindle sheave, loosen the

two set screws (C, Figure 25), and slide the

sheave off the spindle.

8. Install the new spindle sheave, loosely

securing the two set screws. Make sure the

sheave is oriented properly.

9. Slide the spindle back into place, install

tabbed lock washer (C, Figure 26), and

bearing lock nut (B, Figure 26). Check for

any spindle play at this point (See

“Checking Spindle Play” section).

10. Re-install the handwheel and tighten the set

screws (A, Figure 26).

11. Align the new sheave (see “Sheave and Belt

Alignment”) then tighten the two set screws

(C, Figure 26) securely on the sheave.

12. Loosen the pivot lock handle and lower the

motor using the tension handle. Re-tighten

the pivot lock handle.

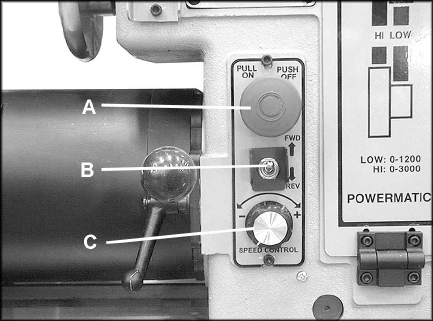

Operating Controls

See Figure 27.

(A) On/Off Button: Push in to stop the machine;

pull out to start the Lathe.

NOTE: If there is a power outage while

operating the Lathe, the Lathe will not

automatically restart once power is restored.

Cycle the on/off switch in order to restart the

machine.

Figure 27