24

5. Once the workpiece is roughed down to a

cylinder, smooth it with a large skew. Keep

the skew handle perpendicular to the spindle

and use only the center third of the cutting

edge for a long smoothingcut (touching one

of the points of the skew to the spinning

workpiece may cause a catch and ruin the

workpiece).

6. Add details to the workpiece with skew,

parting tool, scraper or spindle gouge.

Beads

1. Make a parting cut for what is to be a bead

to the desired depth. Place the parting tool

on the tool support and move tool forward to

make the full bevel of the tool come in

contact with the workpiece. Gently raise

handle to make cut to the appropriate depth.

2. Repeat for other side of the bead.

3. Using a small skew or spindle gouge, start in

the center between the two cuts and cut

down each side to form the bead. Roll the

tool in direction of cut.

Coves

1. Use a spindle gouge. With the flute of the

tool at 90 degrees to the workpiece, touch

the point of the tool to the workpiece and roll

in towards the bottom of the cove. See

Figure 34. Stop at the bottom; attempting

to go up the opposite side may cause the

tool to catch.

Figure 34

2. Move the tool over the desired width of the

cove.

3. With the flute facing the opposite direction,

repeat step 1 for other side of cove. Stop at

bottom of cut.

"V" Cuts

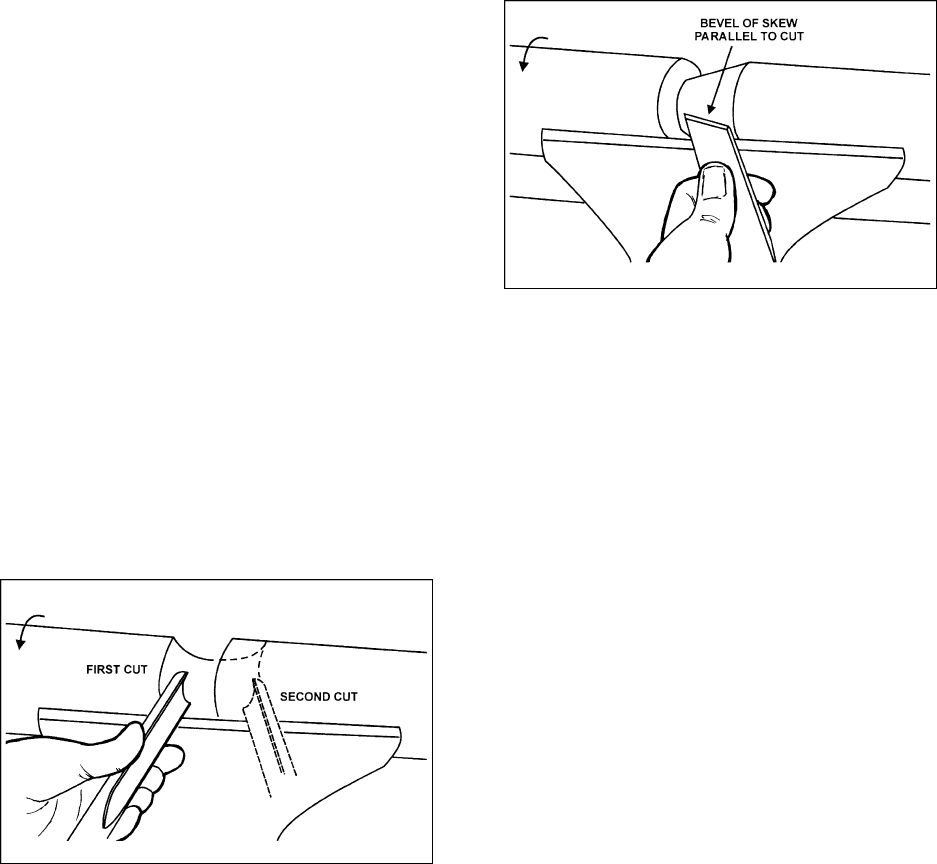

1. Use the long point of the skew. (NOTE: Do

not press the long point of the skew directly

into the workpiece to create the "V"; this will

result in a burned or burnished "V" with

fibers being rolled up at both sides.)

2. Lightly mark the center of the "V" with the tip

of the skew.

3. Move the point of the skew to the right half

of the desired width of your cut.

4. With the bevel parallel to the right side of the

cut, raise the handle and push the tool in to

the desired depth, as shown in Figure 35.

Figure 35

5. Repeat from the left side. The two cuts

should meet at the bottom and leave a clean

"V" cut.

6. Additional cuts may be taken to add to

either the depth or width of the cut.

Parting Off

1. Use parting tool.

2. Adjust lathe speed to lower RPM for parting

through a workpiece.

3. Place tool on tool support and raise the

handle until it starts to cut and continue to

cut toward the center of the workpiece.

4. Loosely hold on to the piece in one hand as

it separates from the waste wood.

Sanding and Finishing

Leaving clean cuts will reduce the amount of

sanding required. Move the tool support out of

the way, adjust the lathe to a low speed, and

begin with fine sandpaper (120 grit or finer).

Coarser sandpaper will leave deep scratches

that are difficult to remove, and dull crisp details

on the spindle. Progress through each grit

without skipping grits (for example, do not jump

from 120 grit to 220 grit). Fold the sandpaper

into a pad; do not wrap sandpaper around your

fingers or the workpiece.

To apply a finish, the workpiece can be left on

the lathe. Turn off the lathe and use a brush or

paper towel to apply the finish. Remove excess

finish before restarting lathe. Allow to dry and

sand again with 320 or 400 grit sandpaper.

Apply second coat of finish and buff.