9

8. The levelers can be adjusted at any time to

ensure the Lathe is stable and level.

9. Set the Lathe right side up (or remove it

from the table).

10. Exposed metal areas of the Lathe, such as

the bed and spindles, have been factory

coated with a protectant. This should be

removed with a soft cloth and a cleaner-

degreaser. Clean the bed areas under the

headstock, tailstock and tool support base.

Do not use an abrasive pad, and do not

allow solvents to contact painted or plastic

areas.

11. Re-install headstock, tool support base, and

tailstock.

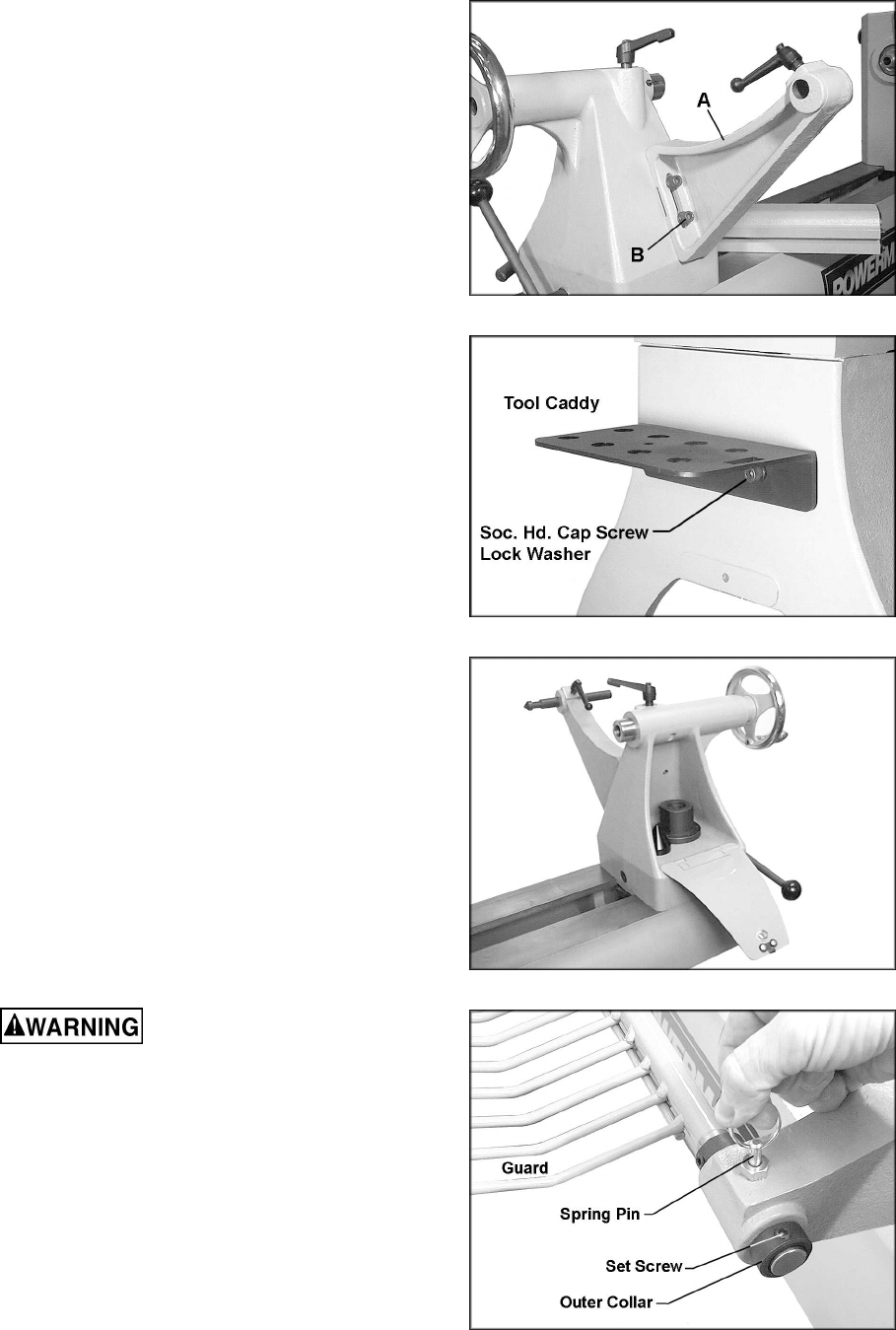

Comparator Rear Bracket

Mount the comparator rear bracket

(A, Figure 2)

to the back of the tailstock with two 3/8 x 1-1/4

socket head cap screws, two 3/8 lock washers

and two 3/8 flat washers (B, Figure 2). The

bracket has a slot so it can be aligned with the

bracket on the headstock. (See “Comparator –

Installing and Using” for further information.)

Tool Caddy

The tool caddy, shown in Figure 3, can be

mounted to the left end or right end of the Lathe.

The left end, near the headstock area, is

generally preferred for convenience. Use two

socket head cap screws and two lock washers

with an 8mm hex wrench to secure the tool

caddy to the threaded holes in the Lathe.

The tool caddy has holes for placing the

knockout rod, spur center, live center, live center

pin, comparator centers, and faceplate wrench.

Accessories can also be stored in the tailstock,

as shown in Figure 4.

Guard

The guard must always be

used in operations that will allow its use.

1. On the guard, loosen the set screw on the

outer collar (shown in Figure 5) with a 4mm

hex wrench. Slide the outer collar off the

guard support rod.

2. Insert the guard support rod into the

mounting bracket at the rear of the

headstock, as shown in Figure 5. You will

have to lift up on the spring pin, as shown,

to slide the guard support rod into the

mounting bracket. Release the spring pin

and it will snap into position as you slide the

support rod farther in.

Figure 2

Figure 3

Figure 4

Figure 5