23

7. Support the workpiece while bringing the

tailstock into position about 1” away from

the end of the workpiece. Lock the tailstock

to the bed.

8. Advance the tailstock spindle with the

handwheel in order to seat the live center

into the workpiece. Use enough pressure to

secure the workpiece between the centers

so that it won’t fly off, but do not use

excessive pressure.

9. Tighten the spindle locking handle.

The tailstock ram is capable

of exerting excessive pressure against the

workpiece and the headstock. Apply only

sufficient force with the tailstock to hold the

workpiece securely in place. Excessive

pressure can overheat center bearings and

damage both workpiece and Lathe.

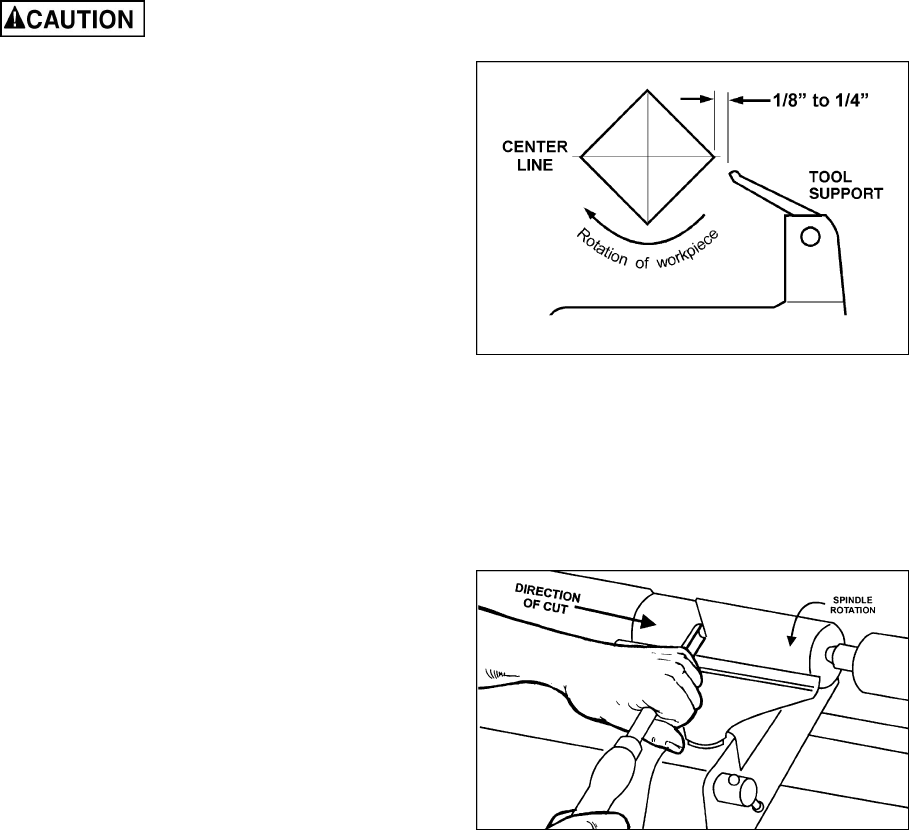

10. Move tool support into position. It should be

parallel to the workpiece, just below the

centerline and approximately 1/8" to 1/4"

from the corners of the workpiece to be

turned, as in Figure 32. Tighten support

base to Lathe bed.

11. Rotate workpiece by hand to check for

proper clearance.

12. Start lathe at lowest speed and bring it up to

the appropriate RPM for the size of

workpiece used. Consult digital readout on

the headstock.

Cutting Techniques

Roughing Out

1. Begin with a large roughing gouge. Place

the tool on the tool support with the heel of

the tool on the surface to be cut.

2. Slowly and gently raise tool handle until

cutting edge comes into contact with the

workpiece.

3. Beginning about 2” from the tailstock end of

the workpiece, roll the flute (hollowed-out

portion) of the tool in the direction of the cut.

See Figure 33. Make long sweeping cuts in

a continuous motion to rough the piece

down to a cylinder.

4. Keep as much of the bevel of the tool as

possible in contact with the workpiece to

ensure control and avoid catches. NOTE:

Always cut down-hill, or from large diameter

to small diameter. Always work toward the

end of a work-piece, never start cutting at

the end.

Figure 32

Figure 33