-21-

M1014 7" x 12" Metal Cutting Bandsaw

MAINTENANCE

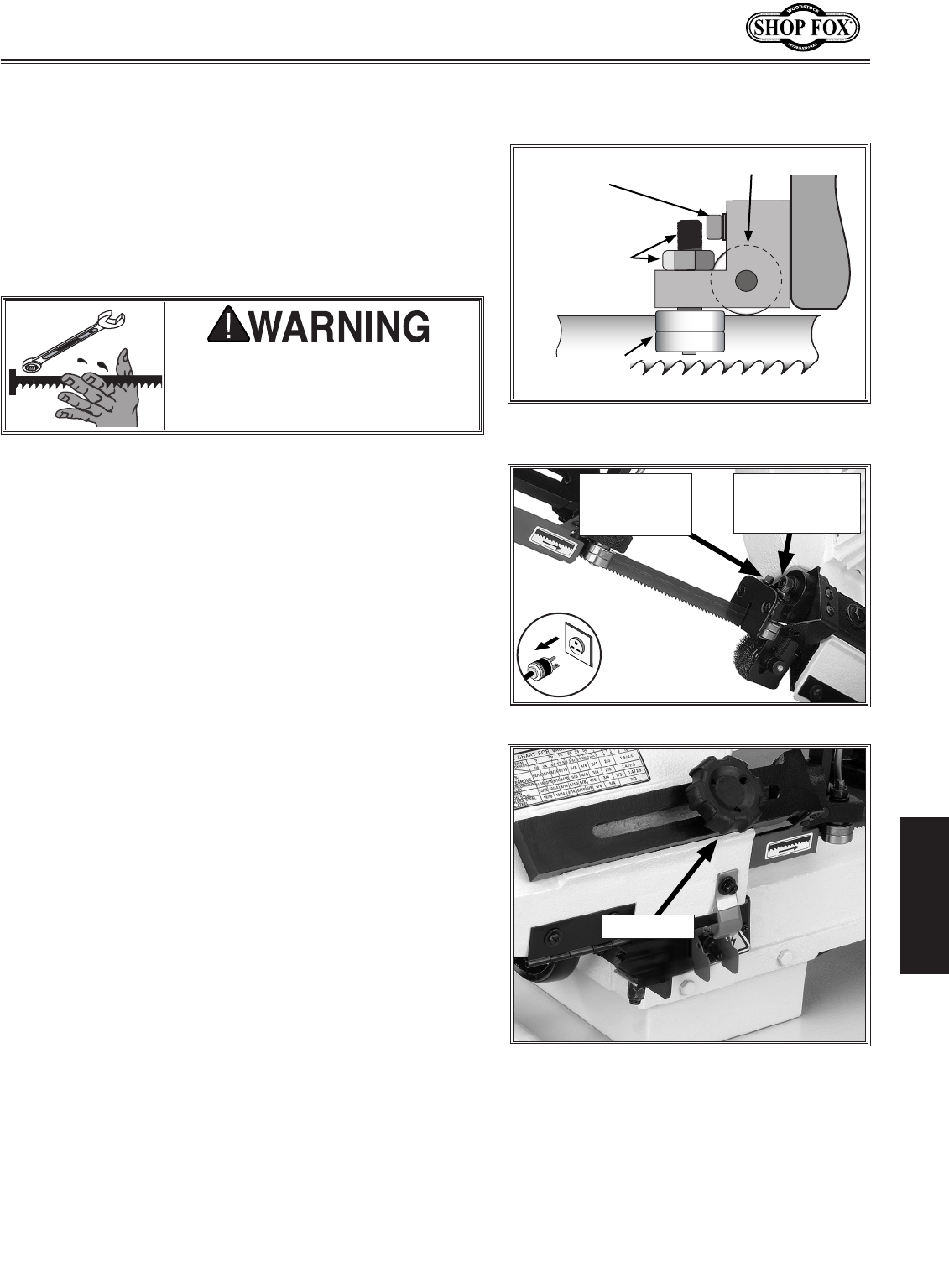

The blade guide side bearings support the blade so the

blade will enter the workpiece perpendicular to the table

surface (see Figure 32).

The blade guide support bearings prevent blade twist by

stopping the blade from being pushed back during a cut.

Both adjustments are the most critical saw adjustments.

To adjust the guide bearings, do these steps:

Note: Make sure the blade is tensioned and tracks

correctly before you adjust the blade guide bearings.

Refer to Blade Tension or Blade Tracking on Pages 20

and 31 for further instructions.

1. UNPLUG THE BANDSAW POWER CORD!

2. Let the bandsaw headstock park in the full down

position.

3. Using a 6mm hex wrench, loosen the guide bearing

adjustment cap screw (see Figures 32 and 33).

4. Adjust the blade guide housing so the support

bearing rests against the rear of the blade (see

Figure 32).

5. Tighten the cap screw.

6. Using a 14mm wrench, loosen the outer side bearing

eccentric jam nuts.

Note: The inner side bearings are not on eccentric

shafts and cannot be adjusted.

7. Using a 6mm wrench, rotate the side bearing

eccentrics (Figure 33) until the bearings hold the

blade perpendicular to the table surface and have a

bearing-to-blade clearance of 0.000" to 0.001". The

bearings must not pinch the blade.

Note: To make sure the blade is perpendicular to

the table, use a standard machinist's square.

8. Tighten the jam nuts and slide the blade guide close

to the workpiece so the blade is supported and will

not twist during the cut (see Figure 34).

Figure 34. Blade guide position lock knob.

Figure 33. Blade guide location.

Blade Guides

UNPLUG the bandsaw power cord,

and NEVER adjust the blade guides

while the saw blade is moving!

Figure 32. Blade guide adjustment

locations.

Guide

Bearing

Adjustment

Cap Screw

Side Bearing

Eccentric

and Jam Nut

Blade Guide

Side Bearing

Blade Guide Support Bearing

Guide Bearing

Adjustment

Cap Screw

Side Bearing

Eccentric

and Jam Nut

Lock Knob