-29-

M1014 7" x 12" Metal Cutting Bandsaw

MAINTENANCE

Lubrication

Since all bearings are sealed and permanently lubri-

cated, simply leave them alone until they need to be

replaced. Do not lubricate them. However, you must

periodically lubricate threaded adjustment locations and

check the gear box oil level.

Lubricate the following areas as follows:

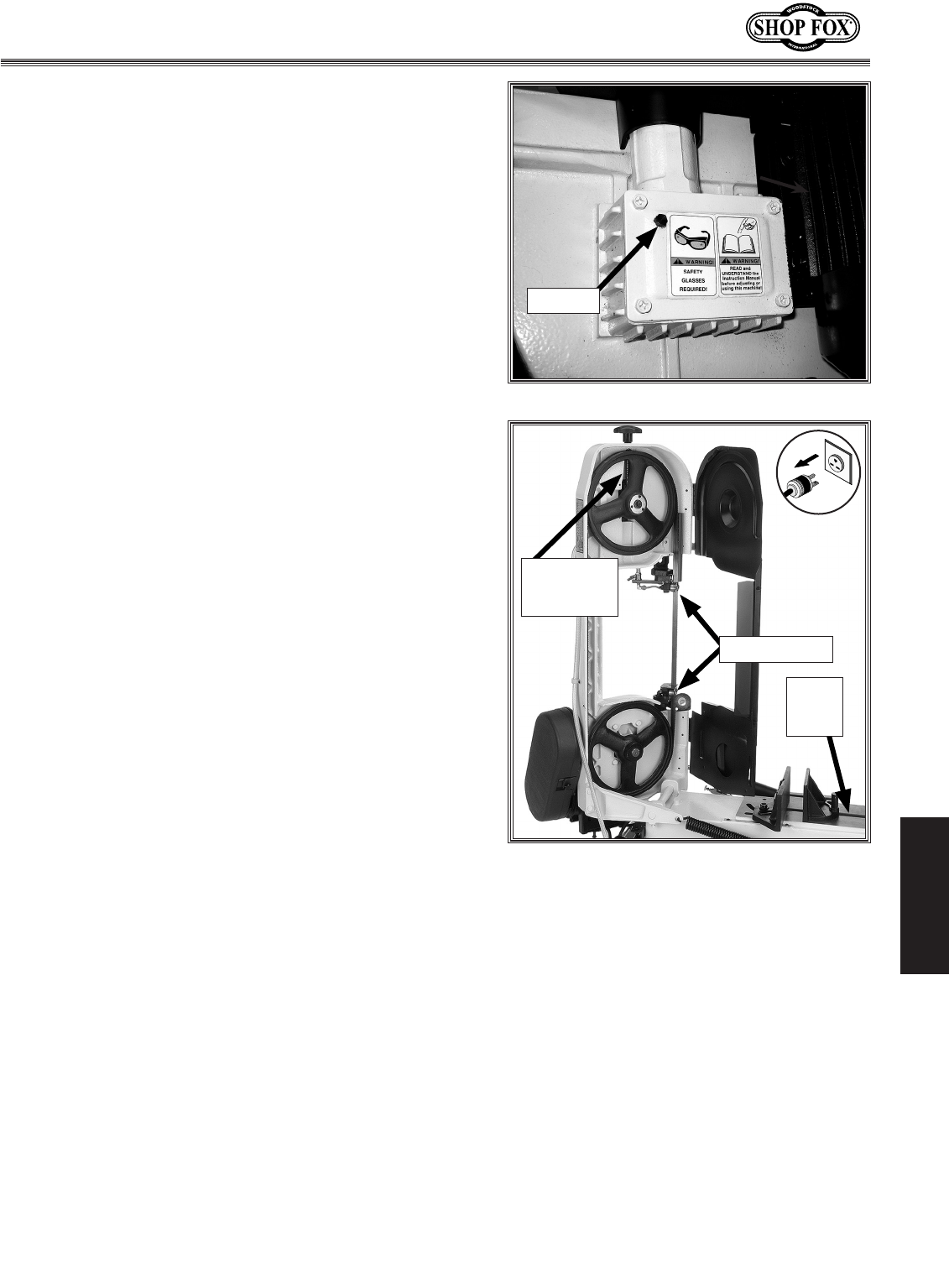

• Gear Box: With the headstock in the down position,

wipe all dirt and metal from the fill plug, remove it,

and check or add 80W-90W gear oil (see Figure 43).

Change the oil every six months under heavy use;

otherwise, change it annually.

• Blade Tension Mechnasim: Open the main blade

guard and drop a few drops of oil on the tension

knob lead screw (see Figure 44).

• Blade and Guides: Drop a few drops of light

machine oil on the blade and the blade guides daily,

especially when cutting cast iron, as no cutting fluid

is recommended.

• Table and Machined Surfaces: Tables can be kept

rust-free with regular applications of products like

SLIPIT

®

. For long term storage you may want to con-

sider products like Boeshield T-9™.

• Vise lead screw: Drop a few drops of light machine

oil on the vise lead screw weekly (see Figure 44).

Figure 43. Gear box.

Fill Plug

Figure 44. Main lubrication points.

Tension

Knob Lead

Screw

Vise

Lead

Screw

Blade Guides