-31-

M1014 7" x 12" Metal Cutting Bandsaw

SERVICE

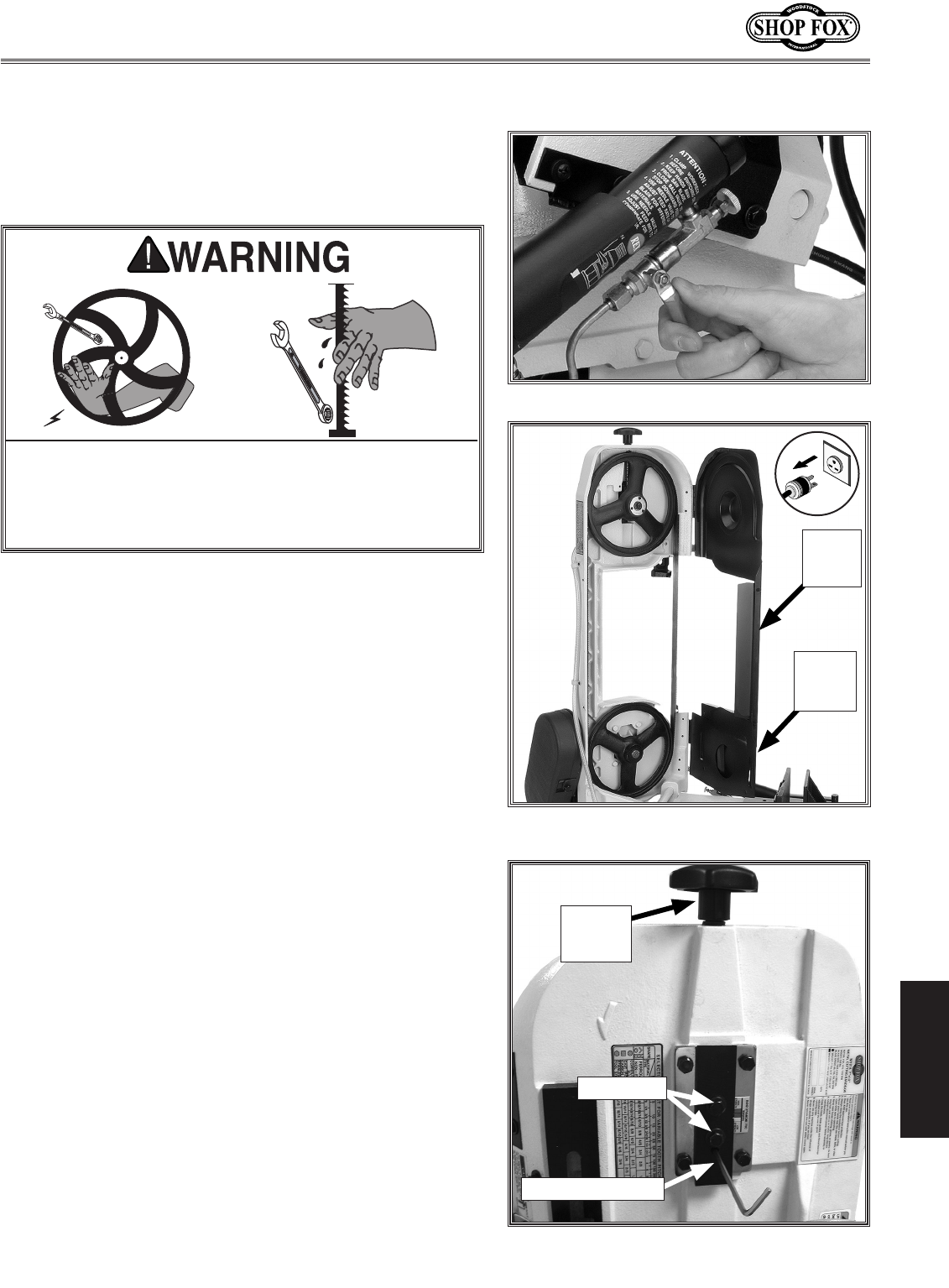

Blade Tracking

A blade that tracks incorrectly can wear out the wheel

flanges or come off of the bandsaw. You must make sure

the blade tracks on the wheel so the rear of the blade is

supported by the lip on the wheel or wheel flange.

To set the blade tension, do these steps:

1. UNPLUG THE BANDSAW POWER CORD!

2. Raise the headstock to the vertical position and

close the feed valve to lock the headstock in place

(see Figure 46).

3. Slide the lower sliding cover up, open the main

blade guard, and remove the blade guide assemblies

(See Figure 47).

4. Plug the bandsaw in and start the machine.

Note: For the next step, turning the set screw and blade

tension knob in opposite directions keeps the blade in

tension during this adjustment process.

5. Using a 4mm hex wrench, adjust the set screw

and blade tension knob simultaneously in opposite

directions, and observe the blade position on the

wheels. If the setscrew does not turn, you may have

to loosen one or both hex bolts shown in Figure 48.

• If tracking is correct, the rear of the blade should

be just touching the wheel flange or wheel

shoulder. Unplug the saw and reinstall and adjust

the blade guides and close the blade guard.

• If there is a gap between the wheel shoulder

or the blade is riding on top of the shoulder,

repeat the adjustment as required to get the

correct tracking.

Figure 46. Stopping the feed cylinder.

Figure 47. Bandsaw blade guard and the

lower sliding cover.

For this next procedure, KEEP hands and tools away

from inside of bandsaw when adjusting the blade

tension; otherwise, severe injury may occur.

ENTANGLEMENT and LACERATION

HAZARD!

Figure 48. Tracking adjustment controls.

Blade

Tension

Knob

4mm Set Screw

Hex Bolts

Lower

Sliding

Cover

Main

Blade

Guard