-27-

W1772/W1773 37" Drum Sander

OPERATIONS

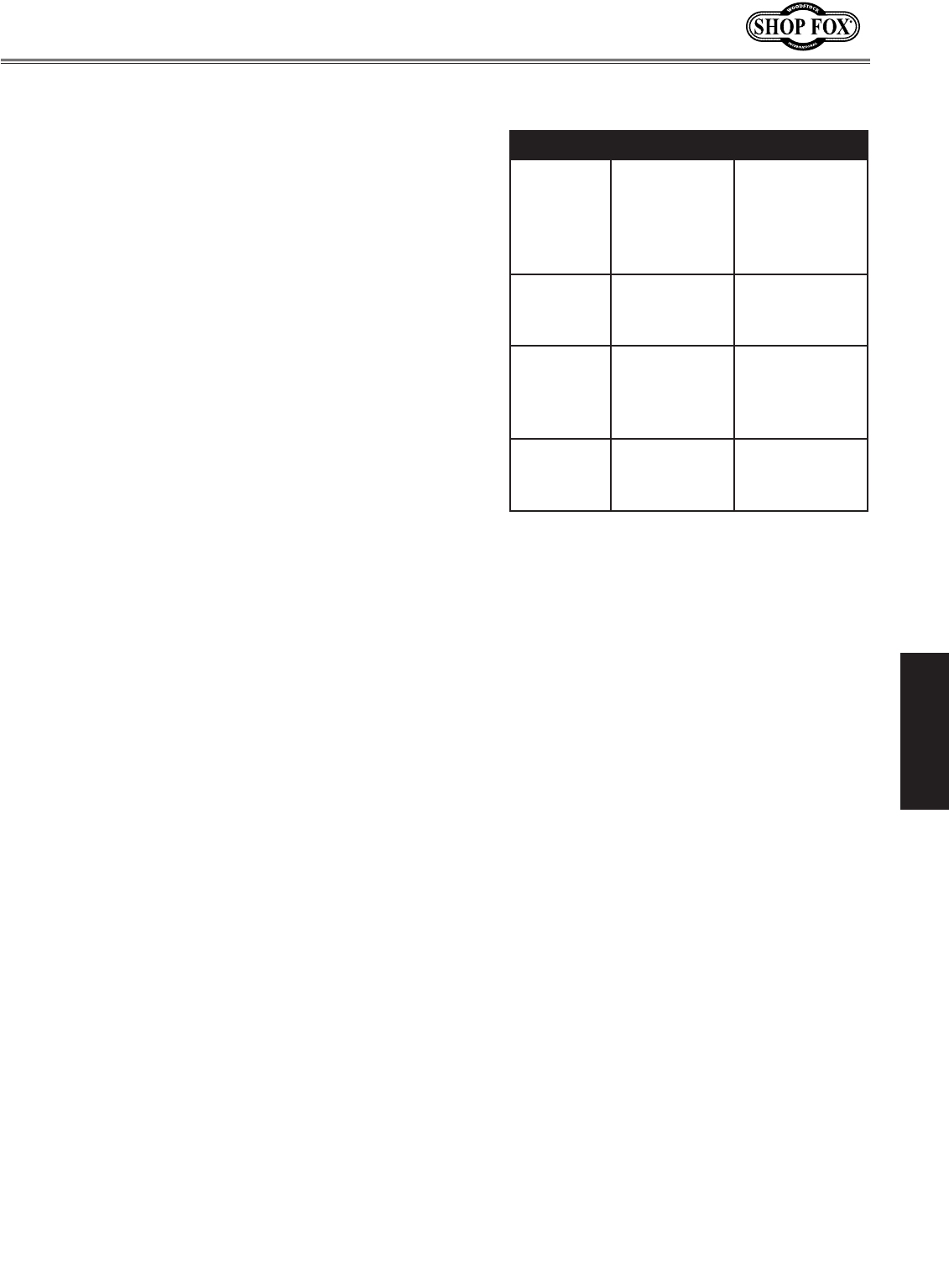

Choosing Sandpaper

There are many types of sanding belts to choose from.

We recommend Aluminum Oxide for general workshop

environments. To the side is a chart that groups abrasives

into different classes, and shows which grits fall into each

class.

The general rule of thumb is to sand a workpiece with

progressively higher grit numbers, with no one grit

increase of more than 50. Avoid skipping grits; the larger

the grit increase, the harder it will be to remove the

scratches from the previous grit.

The Model W1772/W1773 allows you to place a differ

-

ent grit sandpaper on each drum. The front drum should

have a coarser grit than the rear. Usually this translates

into combinations of successive group types. A common

selection for stock that is planed before being sanded is a

100/150 grit combination.

Ultimately, the type of wood you use and your stage of

finish will determine the best grit types to install on your

sander.

Grit Class Usage

36 Extra Coarse Rough sawn

boards, thick

-

ness sand

-

ing, and glue

removal.

60 Coarse Thickness

sanding and

glue removal.

80–100 Medium Removing

planer marks

and initial fin

-

ish sanding.

120–180 Fine Finish sanding.