-56-

W1772/W1773 37" Drum Sander

SERVICE

Troubleshooting

This section covers the most common problems and corrections with this type of

machine. WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop

!

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Machine does not start or a

breaker trips.

1. Emergency stop push-button is

engaged/faulty.

2. Power supply switched OFF or is at

fault.

3. Start capacitor is at fault (W1772

only).

4. Motor connection wired incorrect-

ly.

5. Thermal overload relay has

tripped.

6. Wall fuse/circuit breaker is blown/

tripped.

7. Contactor not getting energized/

has burnt contacts.

8. Wiring is open/has high resistance.

9. Emergency stop push-panel is

stuck/switch is at fault.

10. Motor is at fault.

1. Rotate clockwise slightly until it pops out/replace

it.

2. Ensure power supply is switched on; ensure power

supply has the correct voltage.

3. Test/replace if faulty (W1772 only).

4. Correct motor wiring connections.

5. Unplug machine, open magnetic switch cover, turn

amperage dial on Thermal Protection Circuit Breaker

to a higher amperage setting.

6. Ensure circuit size is suitable for this machine;

replace weak breaker.

7. Test for power on all legs and contactor operation.

Replace unit if faulty.

8. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

9. Free push-panel from binding; replace faulty

switch.

10. Test/repair/replace.

Machine stalls or is over

-

loaded.

1. Feed rate too fast for task.

2. Workpiece material is not suitable

for this machine.

3. Run capacitor is at fault (W1772

only).

4. Belt(s) slipping.

5. Motor connection is wired incor-

rectly.

6. Motor bearings are at fault.

7. Machine is undersized for the task.

8. Contactor not getting energized or

has poor contacts.

9. Motor has overheated.

10. Motor is at fault.

11. Air circulation through the motor

restricted.

1. Decrease feed rate.

2. Only cut wood products; make sure moisture con-

tent is below 20% and there are no foreign materials

in the workpiece.

3. Test/repair/replace (W1772 only).

4. Replace bad belt(s) as a matched set, align pulleys,

and re-tension.

5. Correct motor wiring connections.

6. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

7. Use new sandpaper with appropriate grit; reduce

the feed rate/depth of sanding.

8. Test for power on all legs and contactor operation.

Replace if faulty.

9. Clean off motor, let cool, and reduce workload.

10. Test/repair/replace.

11. Clean off motor to provide normal air circulation.

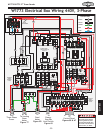

Drums run backwards

(W1773 only).

1. Two of the power wires are reversed

(W1773 only).

1. Switch two of the current carrying wires at the main

power block (W1773 only). (Page 21

)

OFF

Motor & Electrical