26

.

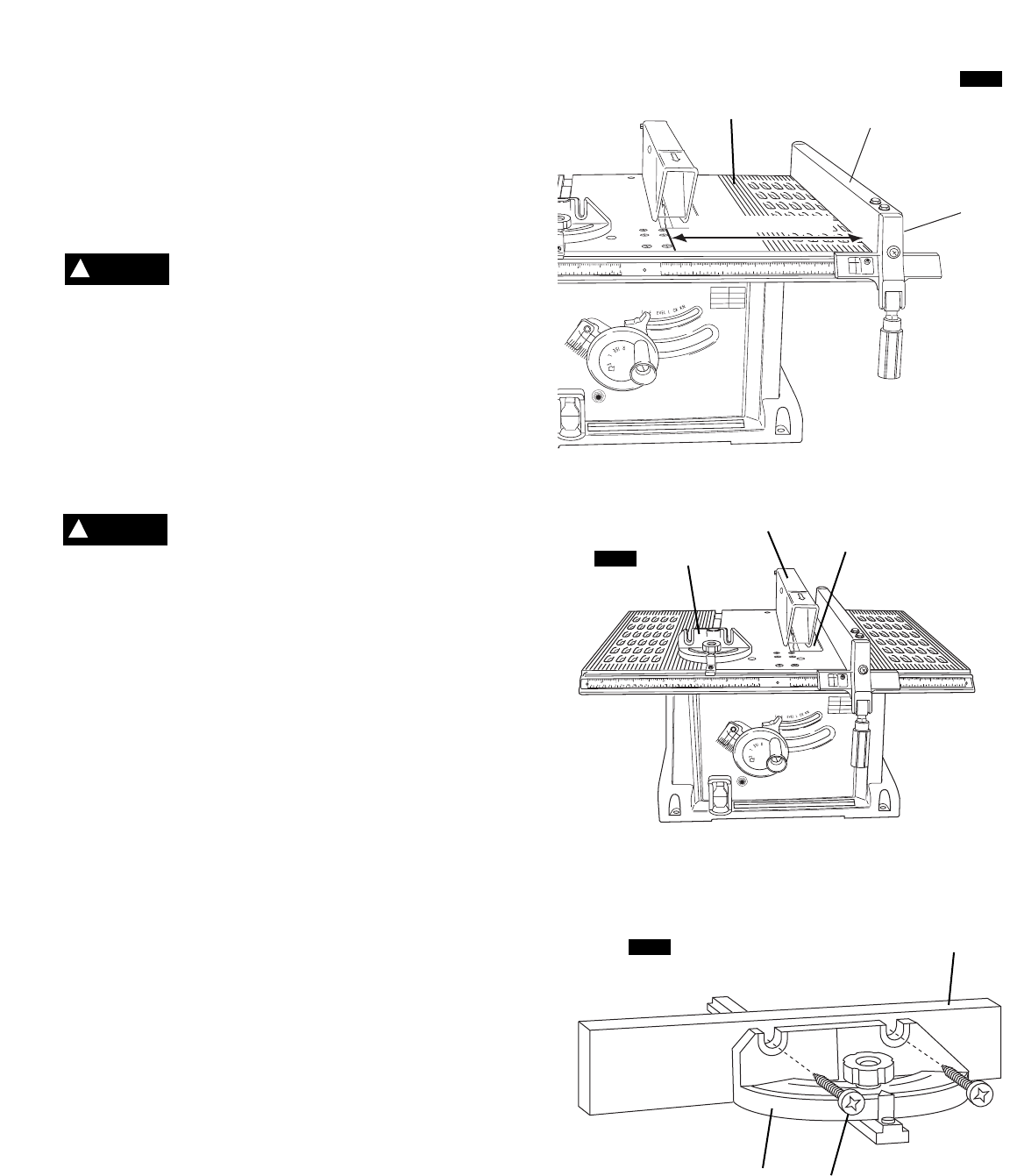

If you are making a rip type cut in thinner materials, the facing

should be attached to the fence so that the bottom edge touches

the top surface of the table. In this situation, the facing must be

lower than the fence. This will prevent thin material from sliding

under the rip fence.

When positioning fence

14 for maximum rip

cutting (without table extension), make sure side

o

f fence housing

(

a)

i

s even with the side edge of the table

2.

Do

not make rip cuts or dado cuts beyond this position because the

fence can not be properly locked. Maximum rip cut capacity is

1

0 3/4 inches (Fig. 5).

15. BLADE GUARD

Protects the operator, and must always be in place and working

properly for all thru-sawing cuts. That is all cuts whereby the blade

cuts completely through the workpiece.

16. TABLE INSERT

Is removable for removing or installing blade or other cutting tools.

For your own safety, turn switch “OFF” and

remove plug from power source before removing

insert.

To remove the insert:

A. Lower the blade below the table surface.

B. Raise blade guard.

C. Remove insert screws and lift insert from pocket in table.

Never operate the saw without the proper insert in place. Use the

saw insert when sawing, and the dado insert when dado cutting.

17. MITER GAUGE

Head can be locked in desired position for crosscutting or mitering

by tightening the lock handle. ALWAYS SECURELY LOCK IT

WHEN IN USE.

Notches are provided in the miter gauge

17 for attaching an

AUXILIARY FACING

(b) to make it easier to cut longer pieces. Be

sure facing does not interfere with the proper operation of the saw

blade guard.

Select a suitable piece of smooth straight wood 3/4" thick, drill two

holes through it and attach it with two round head #10 or #12 round

head screws 1-1/4" long (

c) (Fig. 7).

NOTE: When bevel crosscutting, attach facing so that it extends to

the right of the miter gauge and use the miter gauge in the groove

to the right of the blade.

Getting To Know Your Table

Saw (Continued)

WARNING

!

WARNING

!

b

c

FIG. 7

17

15

Maximum 10 3/4”

FIG. 5

14

2

a

16

FIG. 6

17