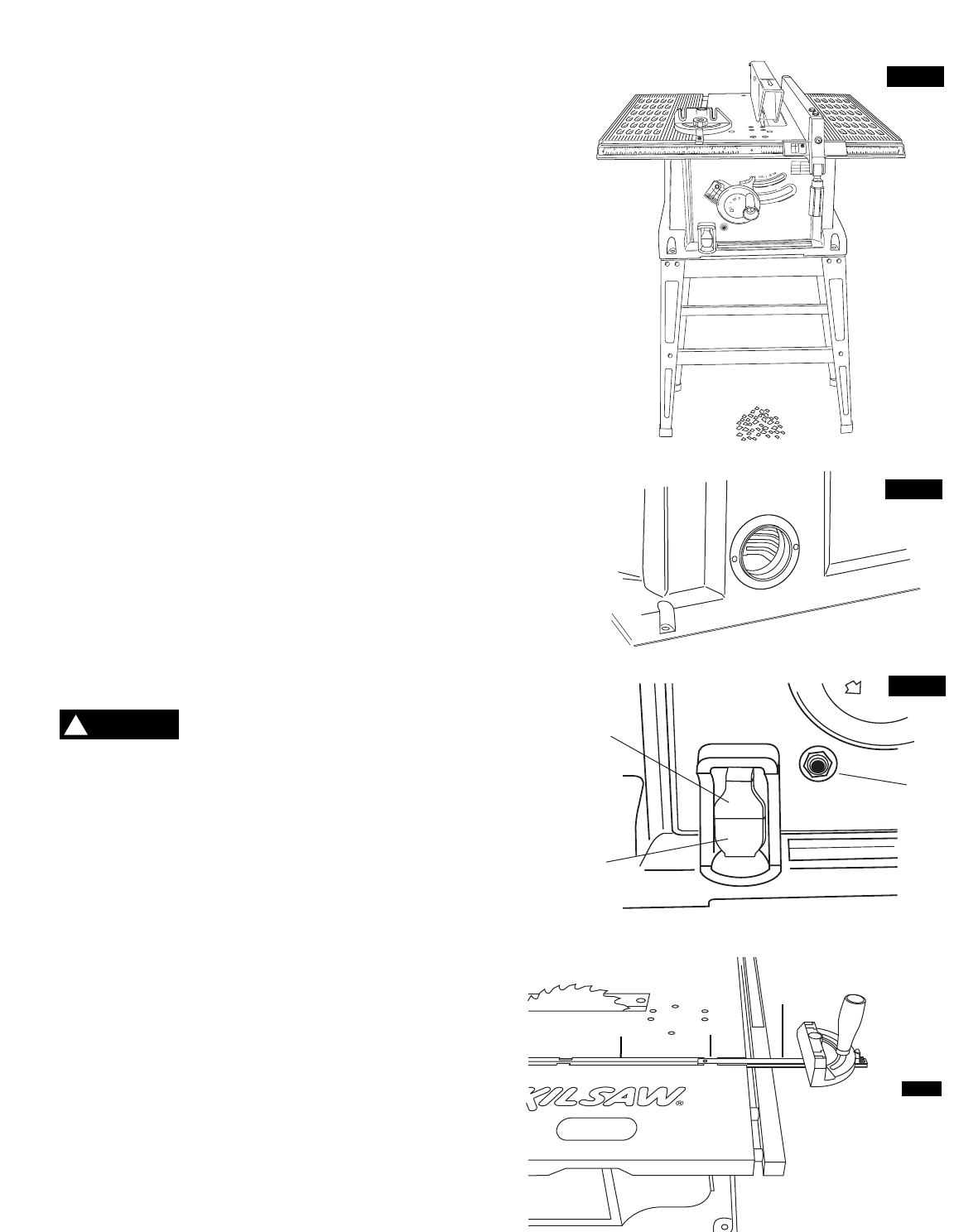

Using the Miter Gauge with “T” Bar

The miter gauge is equipped with a “T” shaped bar 4 which

engages under retaining tabs

5 in the table’s miter gauge slots 6

(Fig. 34).

The tabs keep the miter gauge in the slot and will support it when

pulled beyond the front of table as shown in figure 34. When using

the miter gauge for 90° cross-cuts, the maximum cut capacity is

11-1/2 inches for up to 2 x 12 lumber (actual width= 11-1/4 inches).

The bar must be engaged under slot tabs before attempting any

cutting operation using the miter gauge.

44

.

Basic Table Saw Operation

FIG. 34

4

5

6

Keeping the Area Clean

S

awdust and wood chips that fall under the saw will accumulate on

the floor. Make it a practice to pick up and discard this dust when

you have completed cutting (Fig. 31).

Sawdust Port

The sawdust port is located at the rear of the saw (Fig. 32). A dust

collection system can be attached to this port to aid in the removal

o

f sawdust from the work area.

On/Off Switch with Safety Key

The On/Off switch has a removable safety key to protect against

unauthorized use.

1. To turn the saw ON, insert the safety key

1 into the switch 2

(Fig. 33). Move the switch upward to the ON position.

2. To turn the saw OFF, move the switch downward to the OFF

position.

3. To lock the switch in the OFF position, grasp the safety key

1

and pull it out of the switch. With the safety key removed, the

switch will not operate.

NOTE: If the safety key is removed while the saw is running, the

saw can be turned OFF, but cannot be restarted without inserting

the safety key.

Overload Reset Switch

To prevent accidental startup if the overload

reset switch is pushed, the On/Off switch

should be in the OFF position, and the plug should be removed

from the power source while cool down takes place. Overheating

may be caused by misaligned parts or a dull blade. Inspect your

saw for proper setup before using it again.

This saw has an overload reset switch

3 (Fig. 33) that will allow the

motor to be restarted after it shuts off due to overloading or low

voltage. If the motor stops during operation, perform the following:

1. Turn the On/Off switch

2 to the OFF position.

2.

Wait about five minutes for the motor to cool.

3. Push in the overload reset switch

3.

4. Turn the On/Off switch to the ON position.

1

2

3

F

IG. 31

FIG. 32

FIG. 33

WARNING

!