41

B_04018

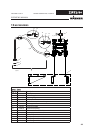

1

2

3

4

5

6

3.5 Nm

2.6 lbft

2 Nm; 1.5 lbft

2 Nm

1.5 lbft

OPERATING MANUAL

VERSION 12/2012 ORDER NUMBER DOC 2330426

9.3 DIAPHRAGM REPLACEMENT DUE TO BREAKAGE

If the diaphragms are replaced as a result of breakage,

all the internal parts of the motor must be cleaned and

the condition of the seals and reversing valve, which

may have been damaged by contact with the pump

uid, must be checked.

a) According to chapter 9.2, points a), b), c) d) and e):

Follow the disassembly procedure of the diaphragms.

b) Disassemble the reversing valve (2).

c) Remove the shaft's plastic bushings (3) located at

each end of the motor block, the lip seals (4) and

the feeler pins (5).

d) Clean all the components, openings and spaces

within the motor block. Blow the housing cavity

of the reversing valve out thoroughly with a jet of

compressed air (wear safety goggles).

e) Check the condition of the reversing valve. If

necessary replace.

f) Grease feeler pins (5) (see chapter 11).

g) Assemble all the parts described under point c) paying attention to properly orient the seals lips (see

chapter 11, exploded view).

h) Grease feeler pins (5) with lip seal (4) once more from outside

i) Put the reversing valve back in its housing. There apply the right torque. Mount the valve slider (6) on one

of the stroke stop positions. There are four possible positions, each of them is suitable.

k) According to chapter 9.2, points f), g), h), i), k) and l):

Reassemble the remaining components.

a) Remove the suction and delivery manifold.

b) Remove the gaskets, seats and balls from the diaphragm covers and the housings of the manifolds.

c) Check the condition of wear of the ball guide/stops inside the diaphragm covers and manifolds. Replace

if worn.

d) Remove all dirt particles as well as hardened material residues. Check the ball and seats for excessive

wear. Clean or replace the components.

e) Clean the contact surfaces of the manifolds and the diaphragm covers and assemble the components. To

the directions in chapter 11 apply the right torque.

It is recommended that the static seals be replaced when reassembling.

9.4 CLEANING / REPLACEMENT OF THE SUCTION AND DELIVERY BALL VALVES