!

The 1594 Planer can be converted to accept

large HSS blades. The conversion requires the

optional PA1204 HSS Blades with Retainers

(pair). (Fig. 7)

Additional pairs of HSS blade, the PA1205

large HSS blades, can also be purchased

separately.

!

1. Rotate the blade drum until the clamping jaw

is parallel to the planer shoe.

2. Loosen the three clamp screws completely

and remove the screws and clamping jaw.

3. Slightly rotate the blade drum and use a

piece of wood to push the blade, holder and

retainer off of the blade drum. Make sure to

keep your fingers away from the sharp

edges of the blade. If the blade is gummed

and difficult to remove, you may clean the

blade and clamp with mineral spirits, lacquer

thinner or alcohol.

4. Rotate the blade drum 180° and repeat the

procedure to remove the second blade.

Before inserting a new or sharpened blade,

clean all surfaces (blades, retainer and drum)

with mineral spirits; lacquer thinner or alcohol,

as this will ensure an accurate blade setting

and proper tool performance.

New or re-sharpened plane blades must be

properly leveled before installation using the

optional PA1206 HSS Blade Leveling Fixture.

(The PA1204 HSS Blades with Retainers are

leveled at the factory.)

To ensure proper operation and an even cut,

the blades must be positioned so that they are:

• Centered relative to the front and rear

shoes.

• Aligned with each other.

• Positioned so that they will not touch against

any part of the planer when rotated.

74(*):7*

1. To install the blades, carefully slide the

blade/retainer assembly sideways to over

one of the two clamping areas on the blade

drum. The retainer must engage in the

groove. (Fig. 8)

2. Place a properly-oriented clamping jaw over

the blade. (Fig. 4)

3. Tighten the three clamp screws with the

Torx key using the correct tightening

sequence (1,2,3). (Fig. 4)

4. Rotate the blade drum 180° and repeat the

procedure for the second blade clamp.

!

47*24;*9-*'1&)*8

1. Rotate the blade drum until the clamping jaw

is parallel to the planer shoe.

2. Loosen and remove the three clamp screws

with the Torx key.

3. Also remove the clamping jaw.

4. Slightly rotate the blade drum and use a

piece of wood to push the blade and retainer

sideways and out of the blade drum. Make

sure to keep your fingers away from the

sharp edges of the blade. If the blade is

gummed and difficult to remove, you may

clean the blade and clamp with mineral

spirits, lacquer thinner or alcohol.

Rotate the blade drum 180° and repeat the

procedure to remove the second blade.

-10-

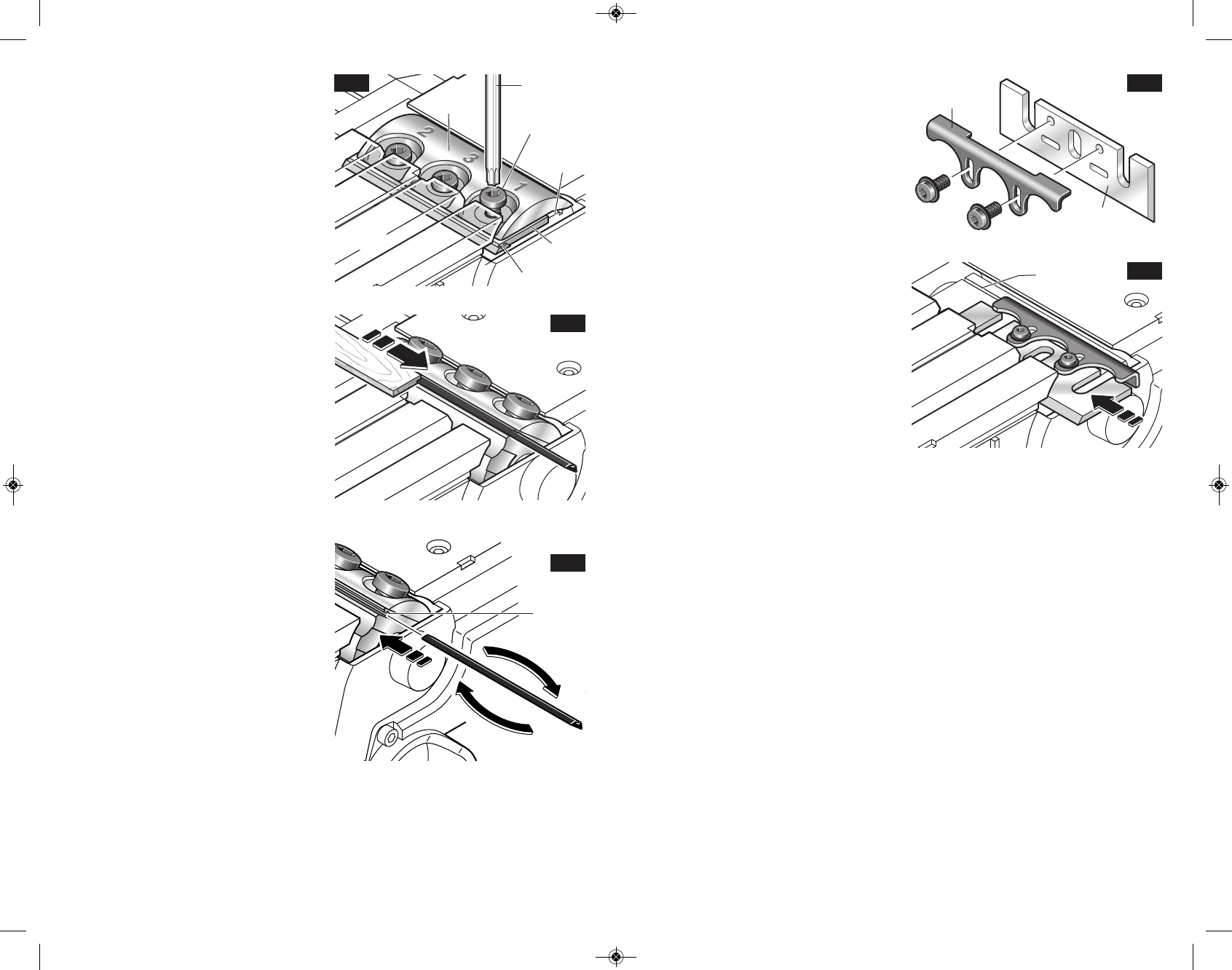

FIG. 8

FIG. 7

HSS

BLADE

GROOVE

-9-

If the blades and/or holder are gummed and

difficult to remove, remove the clamping jaws

and screws and clean all surfaces with mineral

spirits; lacquer thinner or alcohol, as this will

ensure an accurate blade setting and proper

tool performance. (See REMOVAL OF MINI

TC BLADE HOLDERS AND RETAINERS)

To install, carefully slide the blades onto ridges

on the blade holders.

To ensure proper operation and an even cut,

the blades must be positioned so that they are:

• Centered relative to the front and rear

shoes.

• Aligned with each other.

• Positioned so that they will not touch against

any part of the planer when rotated.

• Evenly pressed back toward the holder to

ensure that they are level.

1. Align the groove on top of the blade with the

ridge of the blade holder and carefully slide

the blade onto the blade holder, as shown in

Figure 6.

2. Using a block of wood push the TC blade

back towards the blade holder so that the

inner side of the blade is pressed against

the sloping part of the blade holder. (This will

ensure that the blades are level.)

3. Then tighten the Torx clamping screws

using the correct tightening sequence

(1,2,3), as shown in Figure 4, and your

planer is ready for use.

Blade Retainer Screws - Under normal

circumstances, the position of the retainer on

the mini TC blade holders does not require

readjustment. If fact, the screws that attach the

retainer to the blade holder are factory sealed

with a yellow fastening compound that should

not be disturbed. However, if you believe that

adjustments must be made, proper adjustment

is critical, and it is best performed by a Bosch

Factory Service or Bosch Authorized Service

Center.

FIG. 4

FIG. 5

FIG. 6

CLAMPING

SCREW

FRONT

SHOE

BLADE

HOLDER

RIDGE

CLAMPING

JAW

BLADE

DRUM

BLADE

WRENCH

BLADE

HOLDER

BM 2610028021 01-13_BM 2610028021 01-13.qxp 1/21/13 11:23 AM Page 9