38

Manual de instrucciones y lista de repuestos

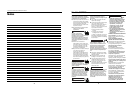

Lista de Repuestos

Modelo WS2800

1 Etiquetas de Advertencia ▲ DK683400AV 1

2 Conector Dinse WC000200AV 2

3 Enchufe Dinse WC000300AV 2

4 Cordón de energía – 230V, 50A (NEMA 6-50P),

7 pies (213 cm), 12AWGX3C, Tipo SJT * 1

5 Cable de soldar – 5 AWG (15mm2) x 10 pies (305 cm) WC000800AV 2

6 Pinza de trabajo – 250A WC100100AV 1

7 Liberador de tensión ▲ WC102400AV 1

8 Portaelectrodo – 300A WC200200AV 1

9 Mango WC301600AV 1

10 Tapón del tubo – 9,94" (24mm) OD WC301601AV 2

11 Tornillo de la máquina – M4-0.7 X 35 mm (Mango) * 4

12 Manivela, Juego de (incluye manivela, perilla, perno, arandelas y tuerca) WC302300SJ 1

13 Interruptor de energía WC402400AV 1

14 Interruptor térmico ▲ WC402500AV 1

15 Luz indicadora – Verde WC402600AV 1

16 Luz indicadora – Amarilla WC402700AV 1

17 Ventilador ▲ WC402800AV 1

18 Eje WC704300AV 1

19 Contratuerca WC704301AV 2

20 Rueda WC704400AV 2

21 Rueda giratoria WC704500AV 2

22 Tornillo de la máquina – M4-0,7 X 10 mm (Rueda giratoria) * 8

23 Puerta WC705100AV 1

24 Pasador de la bisagra ▲ WC705300AV 2

25 Puntero del medidor WC705500AV 1

26 Rejilla del ventilador WC706200AV 1

27 Pasador de la puerta WC706300AV 1

28 Lentes de soldar – Oscuros 10, 2x4-1/4" (51x108mm) ▲ WC801100AV 1

29 Protector manual ▲ WC801300AV 1

30 Martillo/cepillo cincelador ▲ WC803000AV 1

* Piezas estándar, disponibles en su tienda local de venta de ferretería o suministros de soldar.

▲No se muestra

No. de

Ref. Descripción Número Ctd.

Figura 16 - Repuestos

Para mayor información

sobre este producto

llame al 1-800-746-5641

(desde los E.E.U.U.)

1

13

15

17, 26

16

3

12

14 (dentro

de la caja)

4

9

10

11

7

18

19

20

21

22

23

27

24

25

2

5

8

6

Park, Quincy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to the Material Safety Data Sheets

and the manufacturers instructions for

metals, electrodes, coatings and

cleaners.

Installation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate the welder in

an environment that is clean and dry.

Avoid locations exposed to high

temperature, high humidity, dust

and corrosive fumes. High humidity

causes moisture condensation on

electrical components. Moisture can

contribute to corrosion and short

electrical components. Dust and dirt

in the welder retain moisture and

increase wear of moving parts.

● Place the welder in an area that

provides at least twelve inches (305

mm.) of ventilation space at both the

front and rear of the unit. Keep all

obstructions away from this

ventilation space.

● Store electrodes in a clean, dry

location with low humidity, such as

WT2240 Electrode Container, to

preserve the flux coating.

● The welder control panel contains

information regarding proper input

voltage and amperage. Follow the

specifications on the welder front

panel.

● The receptacle used for the welder

must be properly grounded and the

welder must be the only load on the

power supply circuit. Refer to the

Circuit Amps chart under

Specifications for correct circuit

capacity.

● The use of an extension cord is not

recommended for electric arc

welding machines. The voltage drop

in the extension cord may

significantly degrade the

performance of the welder.

Fire

hazard!

Do not weld on containers

or pipes that contain or

have contained flammable

materials or gaseous or liquid

combustibles.

Arc

welding

closed cylinders or

containers such as tanks or

drums can cause explosion if

not properly vented! Verify that any

cylinder or container to be welded has

an adequate ventilation hole, so that

expanding gases can be released.

Do not

breathe

fumes that are produced by

the arc welding operation.

These fumes are

dangerous. If the welding area cannot

be adequately ventilated, be sure to

use an air-supplied respirator.

● Keep the head and face out of the

welding fumes.

● Do not perform electric arc welding

operations on metals that are

galvanized or cadmium plated, or

contain zinc, mercury, or beryllium

without completing the following

precautions:

a. Remove the coating from the

base metal.

b.Make sure that the welding area

is well ventilated.

c. Use an air-supplied respirator.

Extremely toxic fumes are created

when these metals are heated.

The

electro-

magnetic field that is

generated during arc

welding may interfere with the

operation of various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician

prior to performing any electric arc

welding operations.

● Route the electrode and work

cables together and secure with

tape when possible.

● Never wrap arc welder cables

around the body.

● Always position the electrode and

ground leads so that they are on

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Model WS2800

the same side of the body.

● Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

that the welding

area is secure and free of hazards

(sparks, flames, glowing metal or slag)

prior to leaving. Be sure that

equipment is turned off and electrode

is removed. Be sure that cables are

loosely coiled and out of the way. Be

sure that all metal and slag has cooled.

• This product, when used for welding,

produces fumes or gases which

contain chemicals known to the State

of California to cause birth defects

(or other reproductive harm) and, in

some cases, cancer (California Health

& Safety Code Section 25249.5 et

seq.).

• To request Material Safety Data Sheet

(MSDS), visit the Internet at

www.chpower.com or call

1-800-746-5641.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from

Superintendent of Documents, U.S.

Government Printing Office,

Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed

Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA

22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

!

WARNING

!

WARNING

www.chpower.com

3