Step 10—Start-Up

To prevent compressor damage or personal injury, observe

the following:

• Do not overcharge system with refrigerant.

• Do not operate unit in a vacuum or at negative pressure.

• Do not disable low-pressure switch.

To prevent personal injury wear safety glasses, protective

clothing, and gloves when handling refrigerant and observe

the following:

• Back seating service valves are not equipped with Schrader

valves. Fully back seat (counterclockwise) valve stem before

removing gage port cap.

Do not vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

Follow these steps to properly start up the system:

1. The outdoor unit is equipped with a crankcase heater which

operates when the compressor is off. Energize crankcase

heater 24 hr before starting unit. To energize heater only, set

indoor thermostat to OFF position and close power disconnect

to unit.

NOTE: Starting the compressor without a minimum of 12 hr of

crankcase heat prior to initial start-up, may result in a compressor

chattering noise and possible damage to the compressor.

2. Fully back seat (open) liquid and vapor tube service valves.

3. Unit is shipped with valve stem(s) front seated and caps

installed. Replace stem caps after system is opened to refrig-

erant flow (back seated). Replace caps finger tight and tighten

additional 1/12 turn (20 ft-lb torque) with wrench.

4. Close electrical disconnects to energize system.

5. Set room thermostat at desired temperature. Be sure set point

is below indoor ambient and is set low enough to energize

desired speed.

NOTE: Carrier electronic thermostats are equipped with a 15-

minute staging timer. This timer prevents the two-speed system

from operating at high speed until unit has been operating in low

speed for 15 minutes unless there is at least a 5°F difference

between room temperature and thermostat set point. To force high

speed (after a minimum of 2 minutes in low speed), adjust the set

point at least 5° below room ambient.

6. Set room thermostat to COOL and fan control to AUTO or ON

as desired. Wait for appropriate time delay(s). Operate unit for

15 minutes. Check refrigerant charge.

NOTE: If unit has not operated within the past 12 hr or following

a unit power-up, upon the next thermostat high- or low-speed

demand, unit operates for a minimum of 5 minutes in high speed.

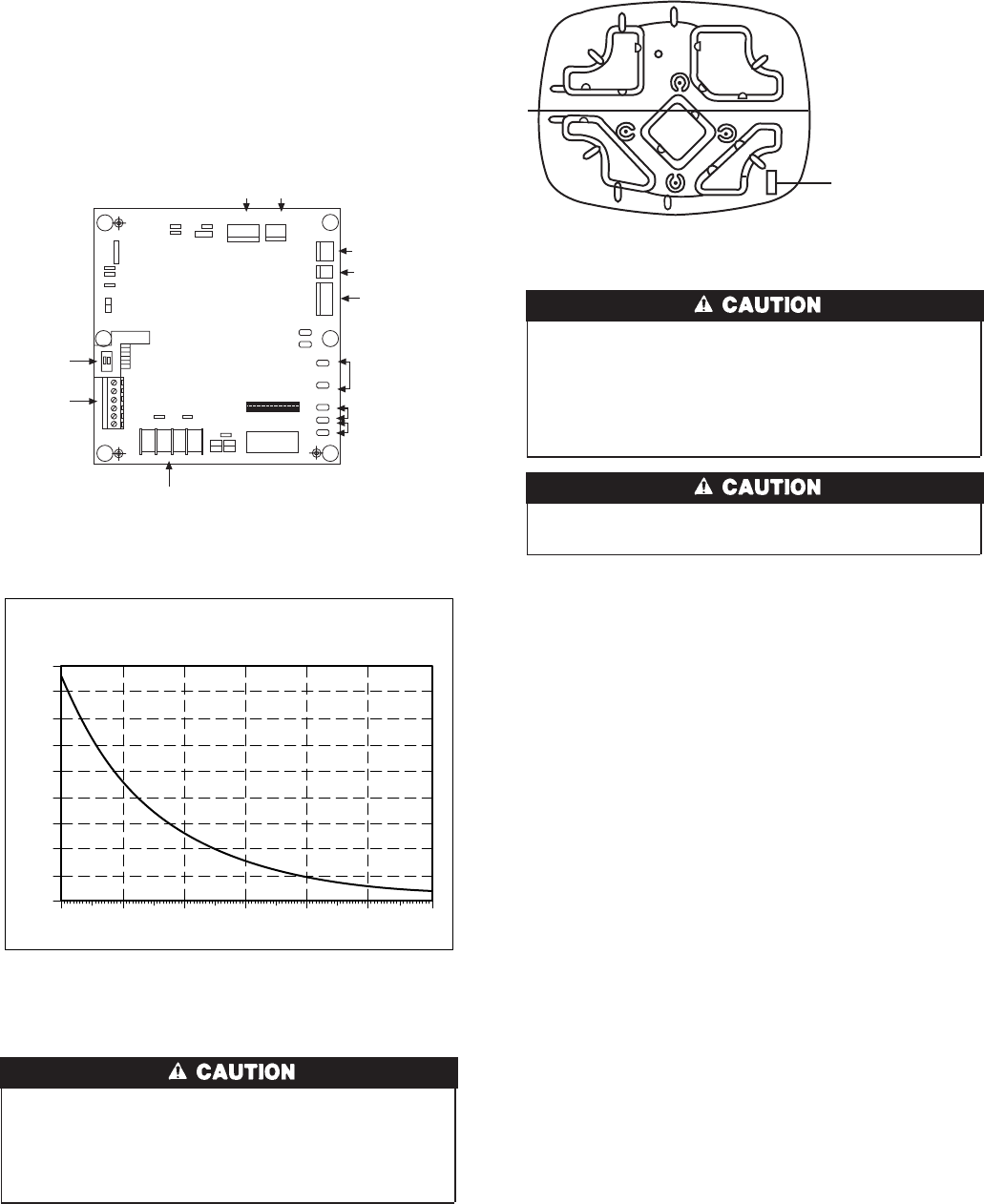

Fig. 12—Control Board

A01192

Defrost Time

Selectors

Thermostat

Low Voltage

Connector

Reserved for

Future Use

Crankcase Heater

Connection

O.D.F. Connection

To Run

Capacitor

Thermistor

Connection

High Pressure

Switch Connector

Low Pressure

Switch Connector

Low/High Speed

Contactor

Connection

Reversing Valve

Connection

CEBD430439-03A

SS0ID

PL1 PL2

HP/AC

C

SEV

RVS

C

HI

LO

PL3

PL4

PL5

OCT OAT HPS LPS

PWM2

PWM1

BRN

BLU

BLK

YEL

RED

CCH L2 ODF VH VC

HK38EA001

K1

CEPL130439-01

COMM STATUS

D51

D52

A B C D

0

Y2

Y1

W1

C

R

120

30

60

60

30

90

DEFROST

TIME (MIN)

R39

R44

R42

C18

C16

R36

FORCED

DEFROST

1

1

1

S1

R89

R91

R87R86

R85

J1

C31

R61

R65

R38

R33

C2

R9

1 2

Fig. 13—Resistance Values Versus Temperature

A91431

0

10

20

30

40

50

60

70

80

90

0 20 40 60 80 100 120

TEMPERATURE (DEG. F)

RESISTANCE (KOHMS)

THERMISTOR CURVE

Fig. 14—View from Top of Base Pan

A00430

THERMISTOR PLACED

UNDERNEATH BASE PAN

(ATTACHED TO BASE PAN

WITH ADHESIVE)

Control Box

Side of Unit

10