INSPECT EQUIPMENT

File claim with shipping company prior to installation if shipment

is damaged or incomplete.

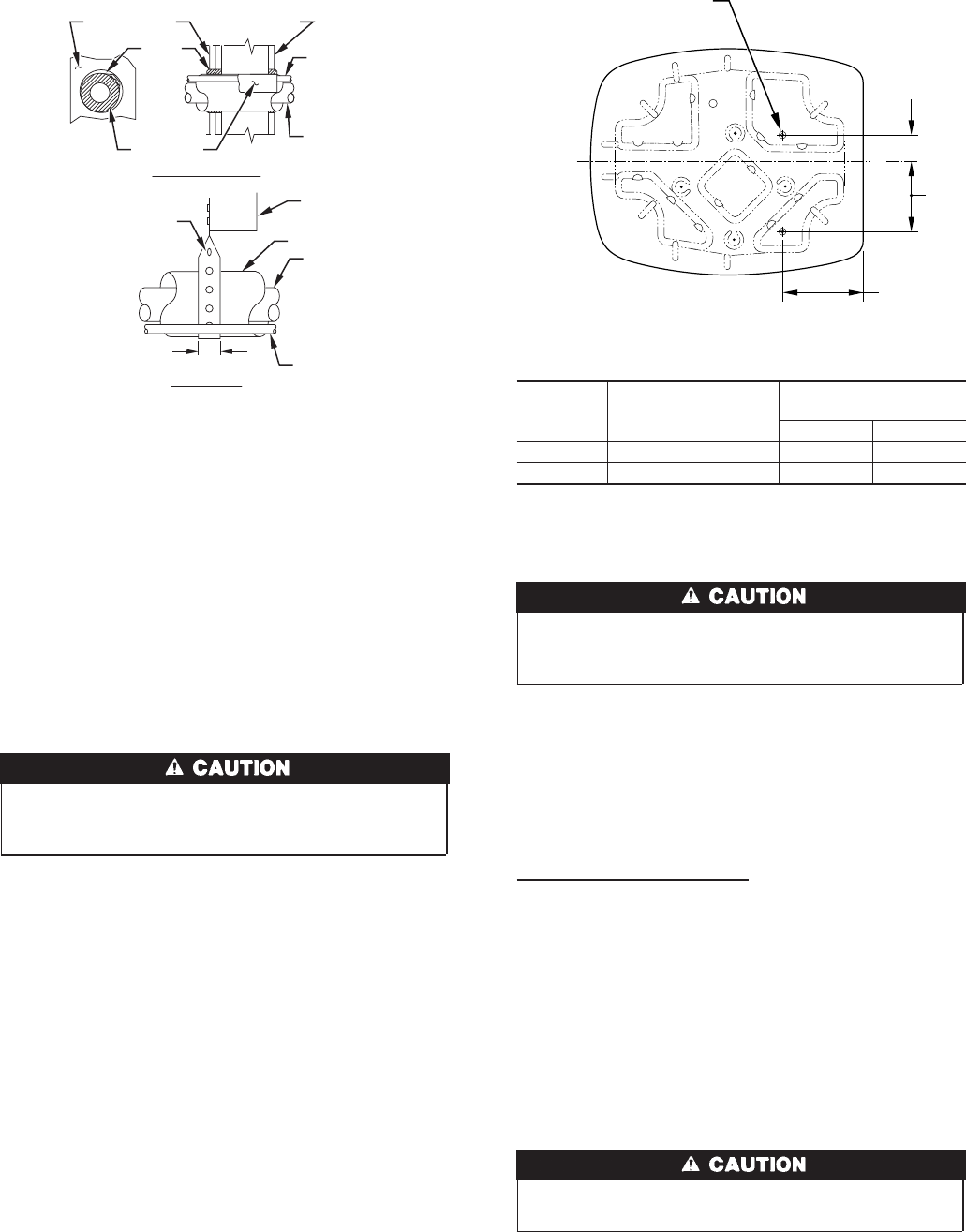

Step 2—Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad, tie

down bolts should be used and fastened through knockouts

provided in unit base pan. Refer to unit mounting pattern in Fig. 3

to determine base pan size and knockout hole location.

On rooftop applications, mount on level platform or frame. Place

unit above a load bearing wall and isolate unit and tubing set from

structure. Arrange supporting members to adequately support unit

and minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Do not allow POE lubricant to come into contact with roofing

material. POE may deteriorate certain types of synthetic

roofing.

NOTE: Unit must be level to within ±2° (±3/8 in./ft).

Step 3—Clearance Requirements

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Allow 30-in. clearance to

service end of unit and 48 in. above unit. For proper airflow, a 6-in.

clearance on 1 side of unit and 12 in. on all remaining sides must

be maintained. Maintain a distance of 24 in. between units.

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

Step 4—Operating Ambient

The minimum outdoor operating ambient in cooling mode is 55°F,

and the maximum outdoor operating ambient in cooling mode is

125°F.

Step 5—Install TXV

Puron® fan coils and furnace coils come factory equipped with a

bi-flow, hard shut off TXV specifically designed for Puron®

two-speed units. No TXV changeout is required. An existing R-22

TXV must be replaced with a factory approved TXV specifi-

cally designed for Puron® two-speed units.

NOTE: FK4, FC4, and 40FK fan coils are equipped with an R-22

TXV. If an FK4, FC4, or 40FK fan coil is used with a Puron® air

conditioner, the R-22 TXV must be replaced with a factory-

approved Puron® TXV.

If indoor unit is equipped with piston, remove indoor coil

piston and replace with balance port hard shutoff TXV

metering device.

IMPORTANT: The 38TDB037 unit includes a factory supplied

TXV kit. All other sizes do not include factory supplied TXV kit.

TXV INSTALLATION

IMPORTANT: The TXV should be mounted as close to the

indoor coil as possible and in a vertical, upright position. Avoid

mounting the inlet tube vertically down. A factory supplied or

approved filter drier must be installed in the liquid line.

Installing TXV in Place of Piston

1. Remove any existing refrigerant and ensure coil has not been

exposed to atmospheric pressure for more than 15 minutes.

2. Remove indoor coil inlet tube at piston body inlet. Use

back-up wrench to prevent damage.

3. Remove piston retainer, begin careful not to damage scaling

surface of O-ring.

4. Remove and discard factory-installed piston. (Replace retainer

if O-ring is damaged.)

5. Reinstall piston retainer in piston body.

6. Replace indoor coil inlet tube. Use back-up wrench to prevent

damage.

To prevent damage to the unit, use a brazing shield and wrap

TXV with wet cloth.

7. Sweat swivel adapter (see Fig. 5D) to inlet of indoor coil and

attach to TXV (see Fig. 5A) outlet. Use backup wrench to

avoid damage to tubing or valve. Sweat Inlet of TXV, marked

“IN” to liquid line. Avoid excessive heat which could damage

valve

Fig. 2—Connecting Tubing Installation

A01383

INSULATION

VAPOR TUBE

LIQUID TUBE

OUTDOOR WALL INDOOR WALL

LIQUID TUBE

VAPOR TUBE

INSULATION

CAULK

Avoid contact between tubing and structureNOTE:

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

JOIST

1″ MIN.

SUSPENSION

Fig. 3—Mounting Unit to Pad

Dimensions (In.)

UNIT SIZE

MINIMUM MOUNTING

PAD DIMENSIONS

TIEDOWN KNOCKOUT

LOCATIONS

AB

024 19 X 24 2-13/16 6-15/16

036-060 26 X 32 4 9-3/4

A97548

C

L

A

B

VIEW FROM TOP

8

3

/

16

″

3

/8-IN. DIA TIEDOWN

KNOCKOUTS IN BASEPAN

(2) PLACES

2

→

→

→

→