EN

ENGLISH

Page -6-

Clarke

®

Operator's Manual (EN) - DC Propane Burnisher

Methods to Reduce The Risks of CO Poisoning

• Air Exchange and CO Diffusion

• Application Considerations (Burnishing versus Stripping)

• Air Quality Monitoring

• Room Size and Time Estimations

• Maintenance of Equipment

• Safety Equipment Available

Air Exchange and CO Diffusion

The most reliable method to prevent CO Poisoning is to ensure all the CO produced is vented outside. With wood

stoves or gas heaters this is performed with ductwork that carries the exhaust and CO outside. Non-stationary

combustion type equipment must be used in such a way that CO is not allowed to rise to a harmful or dangerous level.

CO does not readily dissipate or mix with air on its own. Air currents can “stir” the CO and dilute the concentration

or ppm values by mixing it with the available air. When using equipment over a large area in a short time “stirring”

occurs as you walk, or to say it another way, your Effective Operating Zone is large. When activity is concentrated to a

smaller area as in a stripping application, the Effective Operating Zone is small, and “stirring” must be forced by the use

of fans to increase the Effective Operating Zone and reduce high concentrations of CO.

Air exchange rates (air exchange is defined as the exhausting of internal air to the external atmosphere), the size of

the Effective Operating Zone, amount of CO produced, level of human activity, and the duration of exposure are all

factors in the determination of the production of carboxyhemoglobin and the amount of CO blood saturation.

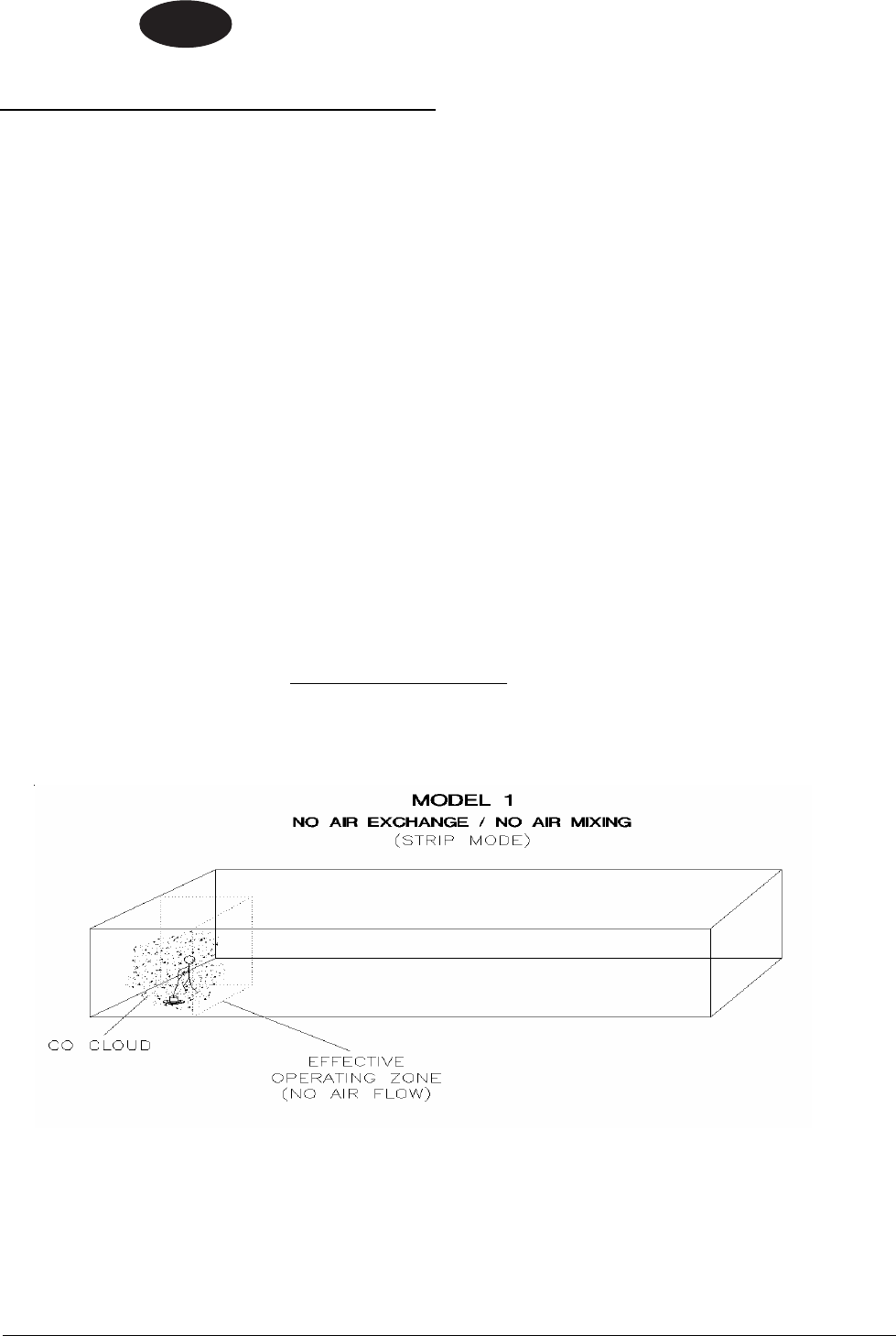

Application considerations (Burnishing versus Stripping)

When using equipment over a large area in a short time, as in most burnishing applications, your Effective

Operating Zone is large. When activity is concentrated to a smaller area as in stripping applications, the Effective

Operating Zone is small and stirring or CO mixing MUST be forced by the use of fans to increase the Effective

Operating Zone and reduce high concentrations of CO.

Caution: air mixing in itself may not be sufficient to reduce CO to a safe level.

The Effective Operating Zone can be defined as the area covered in a given time.

Stripping is quite a different type of operation than burnishing, and carries with it substantially more hazards, as

stripping is a low movement operation compared to burnishing (less floor space for the same time). As shown in Model

1, the CO concentrations rise much quicker as the “Effective Operating Zone” is a very small area compared to the total

building size.