TO CHANGEBLADEDEPTH

See Figure 28.

The blade depth should be set so that the outer points of

the blade are higher than the workpiece by approximately

1/8 in. to 1/4 in. but the lowest points (gullets) are below

the top surface.

[] Raise the blade by turning the height/bevel adjusting

handwheel clockwise or lower it by turning the hand-

wheel counterclockwise.

GULLET

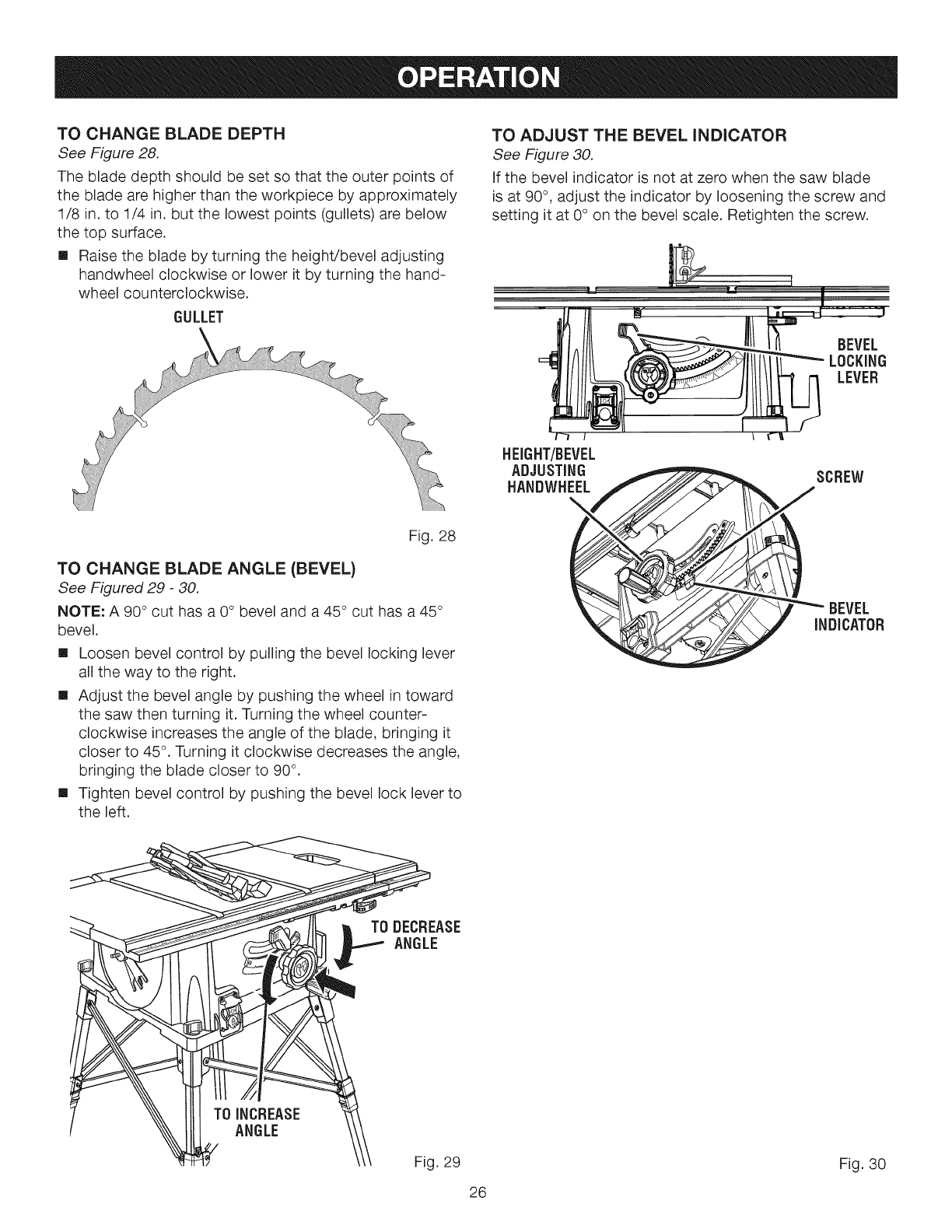

TO ADJUST THE BEVEL INDICATOR

See Figure 30.

If the bevel indicator is not at zero when the saw blade

is at 90°, adjust the indicator by loosening the screw and

setting it at 0° on the bevel scale. Retighten the screw.

LJ

BEVEL

LOCKING

LEVER

HEIGHT/BEVEL

ADJUSTING

HANDWHEEL

SCREW

Fig. 28

TO CHANGE BLADE ANGLE (BEVEL)

See Figured 29 - 30.

NOTE: A 90° cut has a 0° bevel and a 45° cut has a 45 °

bevel.

[] Loosen bevel control by pulling the bevel locking lever

all the way to the right.

[] Adjust the bevel angle by pushing the wheel in toward

the saw then turning it. Turning the wheel counter-

clockwise increases the angle of the blade, bringing it

closer to 45°.Turning it clockwise decreases the angle,

bringing the blade closer to 90°.

[] Tighten bevel control by pushing the bevel lock lever to

the left.

BEVEL

INDICATOR

ODECREASE

ANGLE

ANGLE

Fig. 29

26

Fig. 30