11

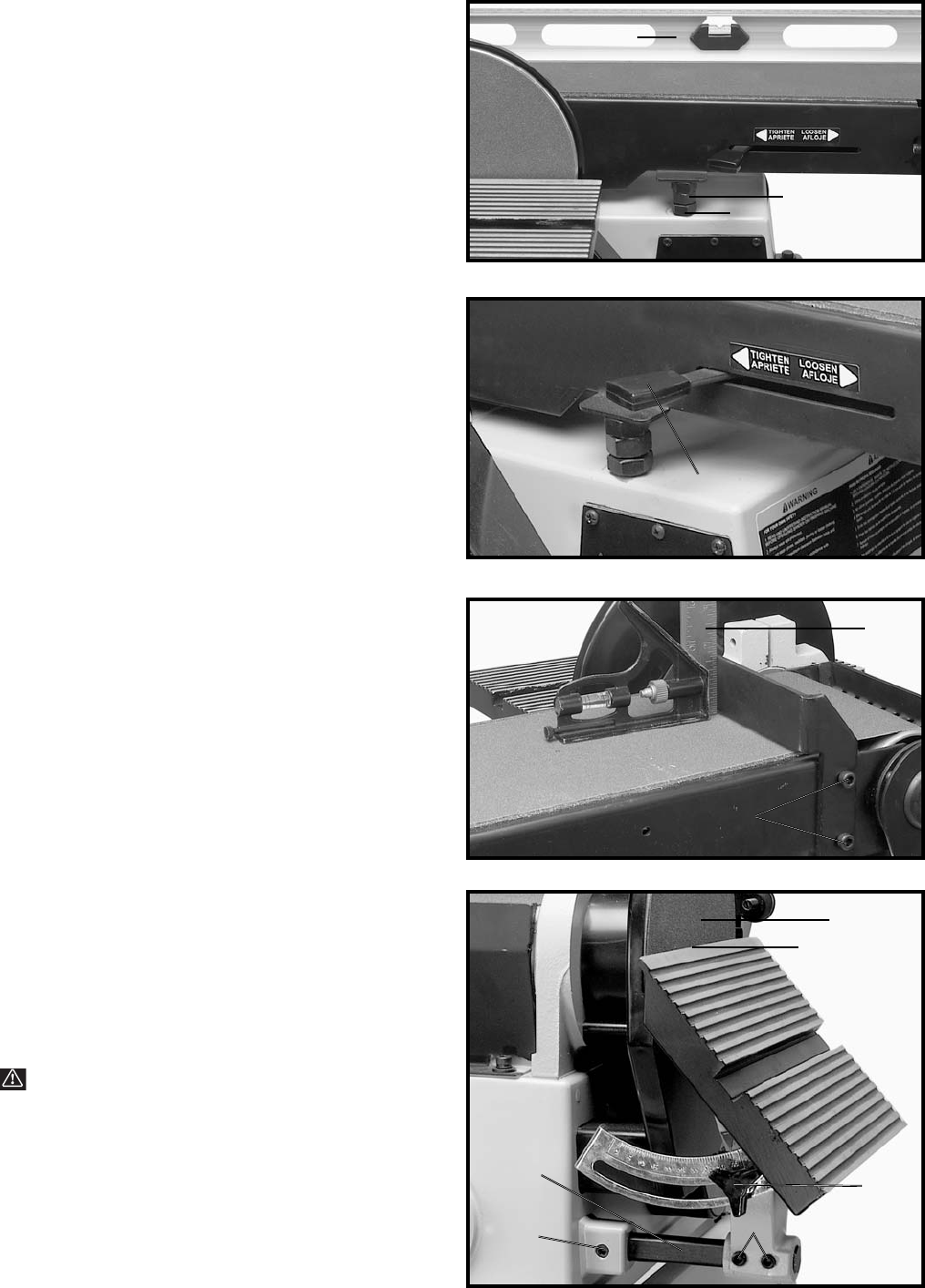

Fig. 24

Fig. 25

Fig. 26

ADJUSTING SANDING

ARM STOP

A positive stop is provided to position the sanding arm

level with the workbench when the arm is in the

horizontal position.

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. Place the sanding arm as far as possible in the hori-

zontal position.

3. Place a level (A) on the sanding belt and check to see

if the arm is level, as shown in Fig. 24.

4. If an adjustment is necessary, loosen lock nut (B)

Fig. 24, and turn sanding arm stop (C) in or out until the

sanding arm is level. Then tighten lock nut (B).

ADJUSTING BACKSTOP

SQUARE WITH

SANDING BELT

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. When making this adjustment make sure the belt

tension lever (A) Fig. 25, is all the way to the left in the

tensioned position, as shown.

3. Place a square (B) Fig. 26, on the sanding belt with

one end of the square against the backstop, and check

to see if the backstop is square with the sanding belt.

4. If an adjustment is necessary, loosen two screws (C)

Fig. 26, and adjust the backstop accordingly. Tighten

screws (C) after adjustment is made.

Fig. 27

TILTING THE TABLE

1. DISCONNECT MACHINE FROM POWER SOURCE.

2. The table can be tilted up to 45 degrees to the right

by loosening the table lock knob (A) Fig. 27, tilting the

table to the desired angle, and tightening table lock

knob (A).

3. WARNING: AFTER TILTING, THE TABLE AS-

SEMBLY MUST BE REPOSITIONED ON THE

SUPPORT ROD (B) FIG. 27, TO PROVIDE A

MAXIMUM OF 1/16 INCH DISTANCE BETWEEN THE

SANDING DISC (C), AND THE EDGE (D) OF THE

TABLE, TO AVOID TRAPPING THE WORK OR

FINGERS BETWEEN THE DISC AND TABLE. TO

REPOSITION THE TABLE ASSEMBLY, LOOSEN TWO

SCREWS (E) AND/OR SCREW (F), MOVE TABLE

ASSEMBLY ON ROD (B), AND TIGHTEN SCREWS (E)

AND/OR (F).

B

C

A

A

C

B

C

D

A

E

B

F