7

ASSEMBLY INSTRUCTIONS

WARNING: FOR YOUR OWN SAFETY, DO NOT CONNECT THE SANDER TO THE POWER SOURCE UNTIL

THE MACHINE IS COMPLETELY ASSEMBLED AND YOU READ AND UNDERSTAND THE ENTIRE OWNERS

MANUAL.

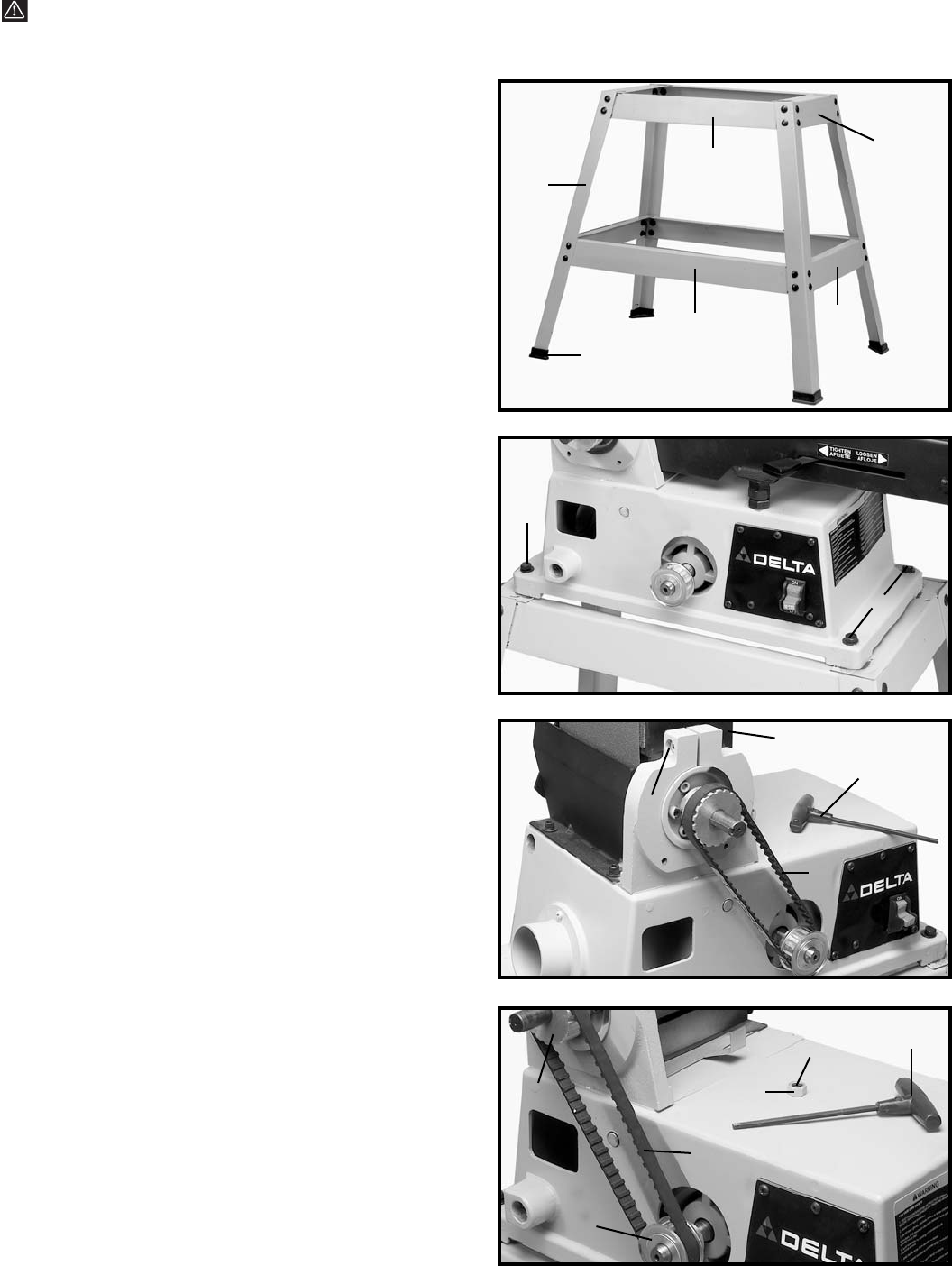

ASSEMBLING STAND

IMPORTANT: ANY LETTER DESIGNATIONS THAT

MAY BE STAMPED ON THE BRACES OF THE STAND

ARE FOR PRODUCTION PURPOSES ONLY AND ARE

NOT USED FOR ASSEMBLING THE STAND. TO

ASSEMBLE THE STAND, PLEASE FOLLOW THE

INSTRUCTIONS DESCRIBED BELOW. SIZES ARE

GIVEN TO HELP IDENTIFY THE COMPONENTS OF

THE STAND.

1. Assemble the stand, as shown in Fig. 4. Align the

holes in the stand and fasten the stand together by

inserting a M8X20mm carriage head bolt through the

hole and place a 3/8" flat washer onto the carriage head

bolt and thread a M8 hex nut onto the screw and tighten

securely, repeat this process for the thirty one remaining

holes. The two 11-1/2" long upper braces (A); 21-5/16"

long upper braces (B); 17-1/8" long lower braces (C); and

26-5/8" long lower braces (D) should be fastened to the

four 27-1/2" long legs (E). IMPORTANT: The top angles

of the upper braces (A) should be on top of the top

angles of upper braces (B).

2. Assemble a plastic foot (F) Fig. 4, to the bottom of

each leg (E) as shown.

ASSEMBLING MACHINE

TO STAND

Carefully set the sander on the stand. Align the four holes

on the top of stand (A) Fig. 5, with four mounting holes at

the base of sander (B). Place a 3/8" flat washer onto a

M8 x 45mm hex head screw (C), insert screw through

hole in base of sander (B) and stand (A). Place a 3/8" flat

washer onto the screw and thread a M8 hex nut onto the

screw and tighten securely, repeat this process for the

three remaining holes.

ASSEMBLING DRIVE BELT

AND ADJUSTING

BELT TENSION

1. With hex wrench (A) Fig. 6 supplied, loosen screw (B)

and move sanding arm (C) to the vertical position; tighten

screw (B) as shown. Assemble drive belt (D) to pulleys.

2. NOTE: The drive belt (D) Fig. 7, should be firm but

not too tight on the pulleys, the drive belt (D) should

have approximately 1/4" to 1/2" deflection in the belt

at the center span on the pulleys (E) and (F) using

light finger pressure. The drive belt (D) does not

require excessive tension to function properly. To

adjust belt tension, loosen locknut (G) Fig. 7. Using

wrench (A) tighten or loosen adjustment screw (H) until

correct belt tension is obtained. Then tighten locknut (G).

3. After drive belt (D) Fig. 7, is tensioned properly, move

the sanding arm to the horizontal position.

Fig. 4

Fig. 5

Fig. 6

Fig. 7

A

B

C

D

E

F

A

B

C

C

B

C

A

D

E

D

F

H

G

A