16

1. Raise the saw blade to its highest position.

2. Set the blade at 90° to the table by turning the blade tilting handwheel counterclockwise as far as it will go.

3. Use a combination square to see if the blade is at 90° to the table surface.

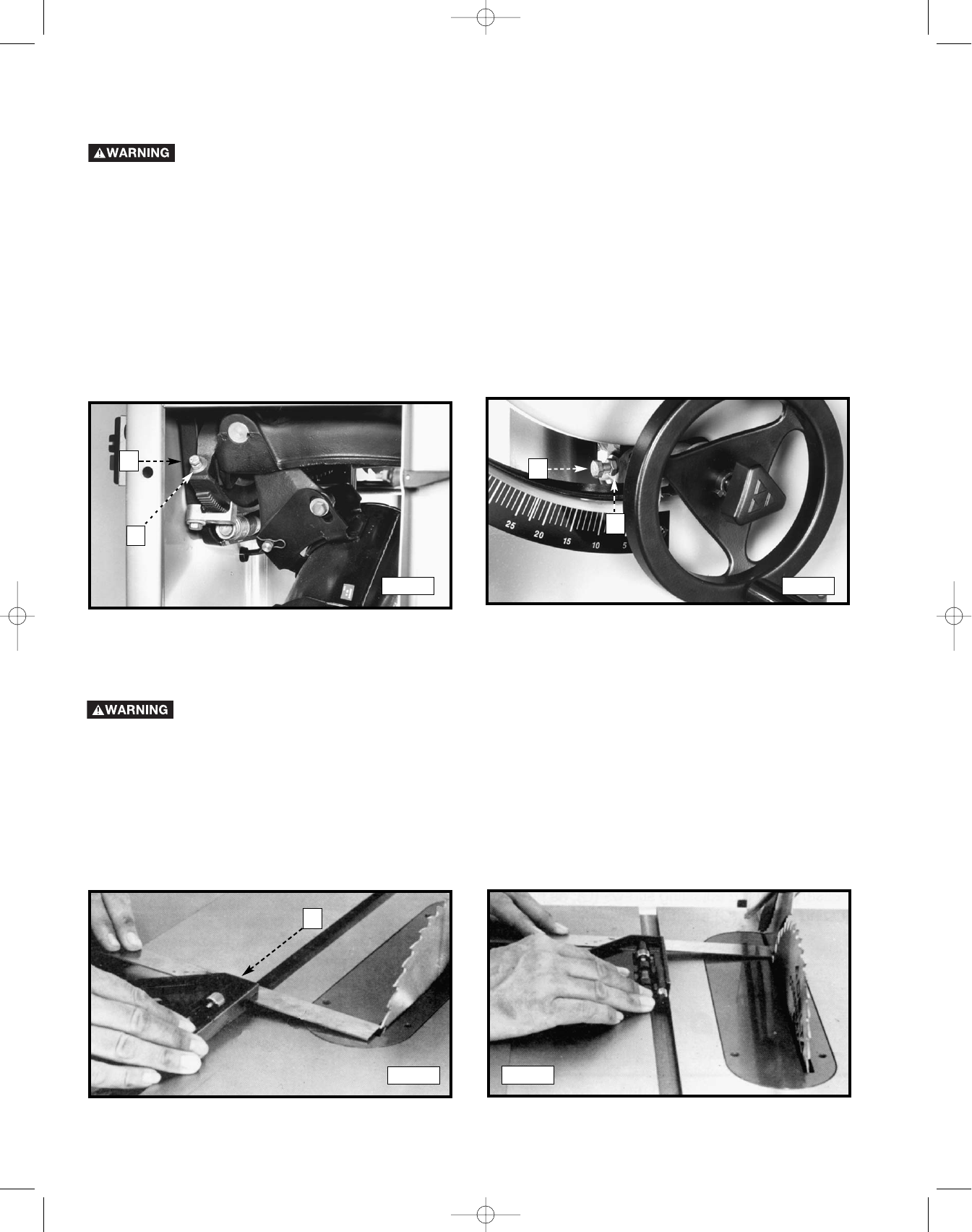

4. If the blade is not at 90° to the table, turn the blade tilting handwheel counter-clockwise. Loosen the locknut (A) Fig.

38, and tighten or loosen adjusting screw (B) until head of screw (B) contacts casting on front trunnion when the blade

is at 90° degrees to the table. Then tighten locknut (A).

5. Check to see if the tilt indicator pointer points to the zero mark on the scale. Adjust if necessary.

6. Turn the blade tilting handwheel clockwise as far as it will go and use a combination square to see if the blade is

at 45° to the table.

7. If the blade is not at 45° to the table, turn the blade tilting handwheel clockwise until the adjusting screw (D) Fig. 43,

and locknut (C) are in view in the opening in the front of the saw cabinet. Loosen the locknut (C) and tighten or loosen

the adjusting screw (D) until the head of the screw (D) contacts the casting on the front trunnion when the blade is

at 45° to the table. Tighten locknut (C).

1. Place a combination square (A) Fig. 40 on the table with one edge of the square in the miter gauge slot. Adjust the

square so that the rule touches one of the teeth on the saw blade (Fig. 40). Lock the square in this position.

2. Rotate the saw blade so that the same tooth you used in STEP 2 is in the rear position (Fig. 45). Both the front and

rear measurements should be identical.

3. To adjust, loosen the four screws that hold the table to the saw cabinet.

4. Shift the table until the saw blade is in the center of the table insert slot, and parallel to the miter gauge slot.

5. Tighten the four screws that were loosened in STEP 4.

6. Tilt the blade to 45°, and turn the saw blade by hand to ensure that it does not contact the table insert.

ADJUSTING 90° AND 45° DEGREE POSITIVE STOPS

Positive stops are provided to quickly and accurately position the blade at 90° and 45° to the table. To check and adjust

the positive stops:

DISCONNECT MACHINE FROM POWER SOURCE!

Fig. 38 Fig. 39

Fig. 40

Fig. 41

ADJUSTING THE TABLE

DISCONNECT MACHINE FROM POWER SOURCE!

The miter gauge slots were aligned parallel to the saw blade at the factory. Check the alignment prior to your initial

operation.

B

A

D

C

A

422-04-651-0064 - 06-20-05.qxd 6/20/05 1:43 PM Page 16