ASSEMBLING UNIFENCE

GUIDE RAIL TO TABLE

1. Locate the Guide Rail and mounting hardware from

the packing material of the Unifence.

2. The guide rail has end caps inserted into each end of

the rail. Remove the end cap (B) Fig. 48, by inserting a

flathead screwdriver (C) into the channel in the guide rail

and press outward against the inside of the end cap (B)

as shown. The end cap (B) will pop out. NOTE: Do not

attempt to remove the end cap by forcing the screwdriver

between the end cap and the end of the rail. This will

damage both the cap and the rail.

Fig. 48

C

B

16

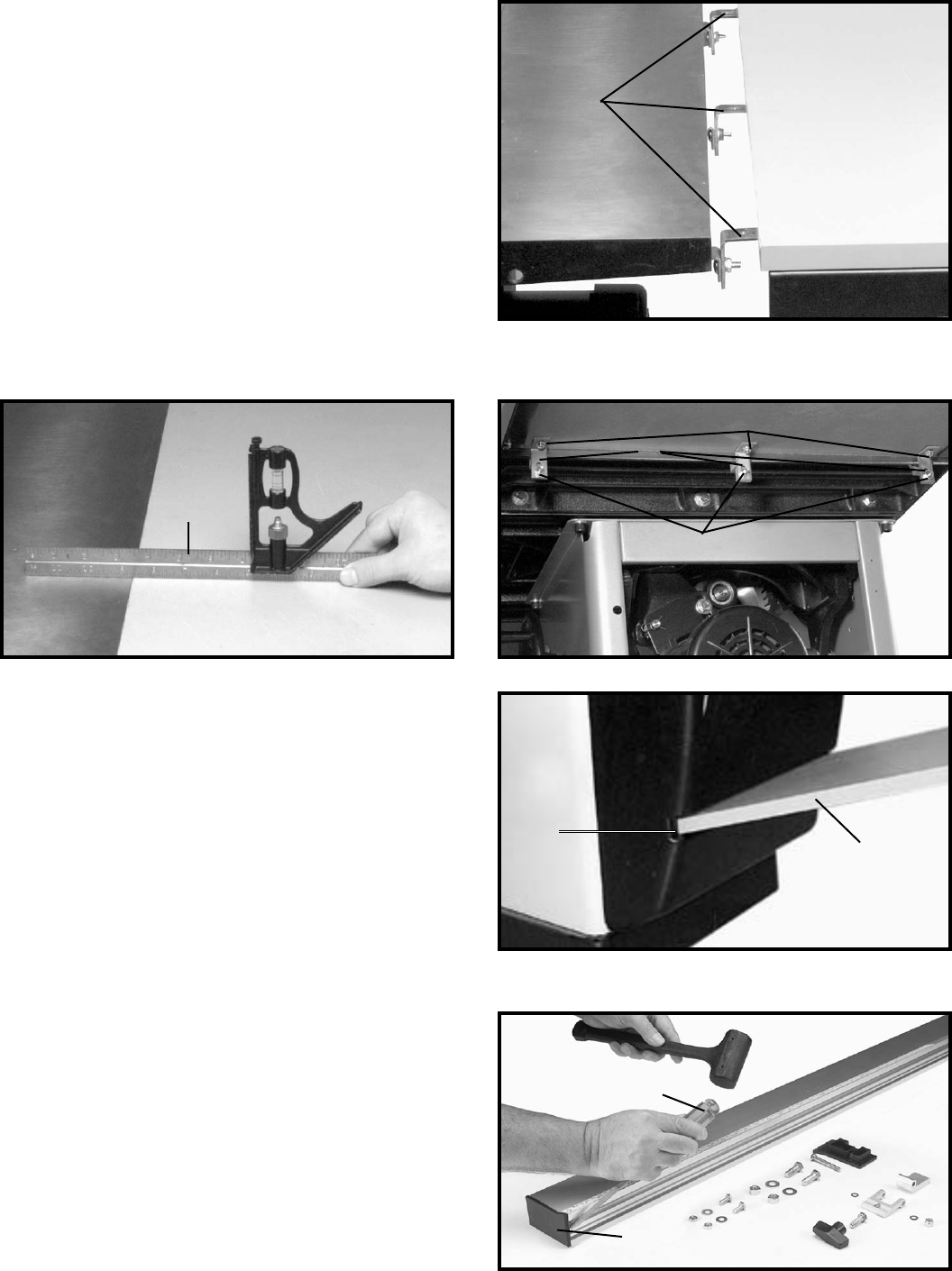

11. Position table board (R) Fig. 45, on top of angle

brackets (N) as shown.

12. While holding table board (R) Fig. 45, tightly against

extension wing (K), fasten table (R) to brackets (N) Fig. 45,

from underneath the table using three #8 x 7/8 inch-long

wood screws (Q) Fig. 47. CAUTION: DO NOT OVER-

TIGHTEN TABLE MOUNTING SCREWS. Over-tighten-

ing screws in particle board may cause them to strip.

13. Using a straight edge (S) Fig. 46, make certain the

Unifence table surface is level with the saw table by

placing a square (S) Fig. 46 on the table board and the

extension wing, and then adjust the brackets (N) Fig. 45,

and then tighten nuts (P) Fig. 45. Place a 3 ft. long level

across the table and adjust the two leveling screws

located on the bottom of table legs. IMPORTANT: Front

edge of Unifence table must be flush with or slightly

behind front edge of saw table.

Fig. 45

N

R

Fig. 47Fig. 46

Q

P

K

S

N

ASSEMBLING UNIFENCE

SHELF BOARD

1. Insert one end of table board (A) Fig. 47A, into the

motor cover slot (B).

2. Fasten the other end of the shelf board to the shelf

support bracket (B) Fig. 36, that was mounted to the

table legs earlier with two #8-7/8" wood screws. NOTE:

ADJUST THE SHELF SUPPORT BRACKET SO THAT

THE SHELF IS LEVEL.

Fig. 47A

A

B