19

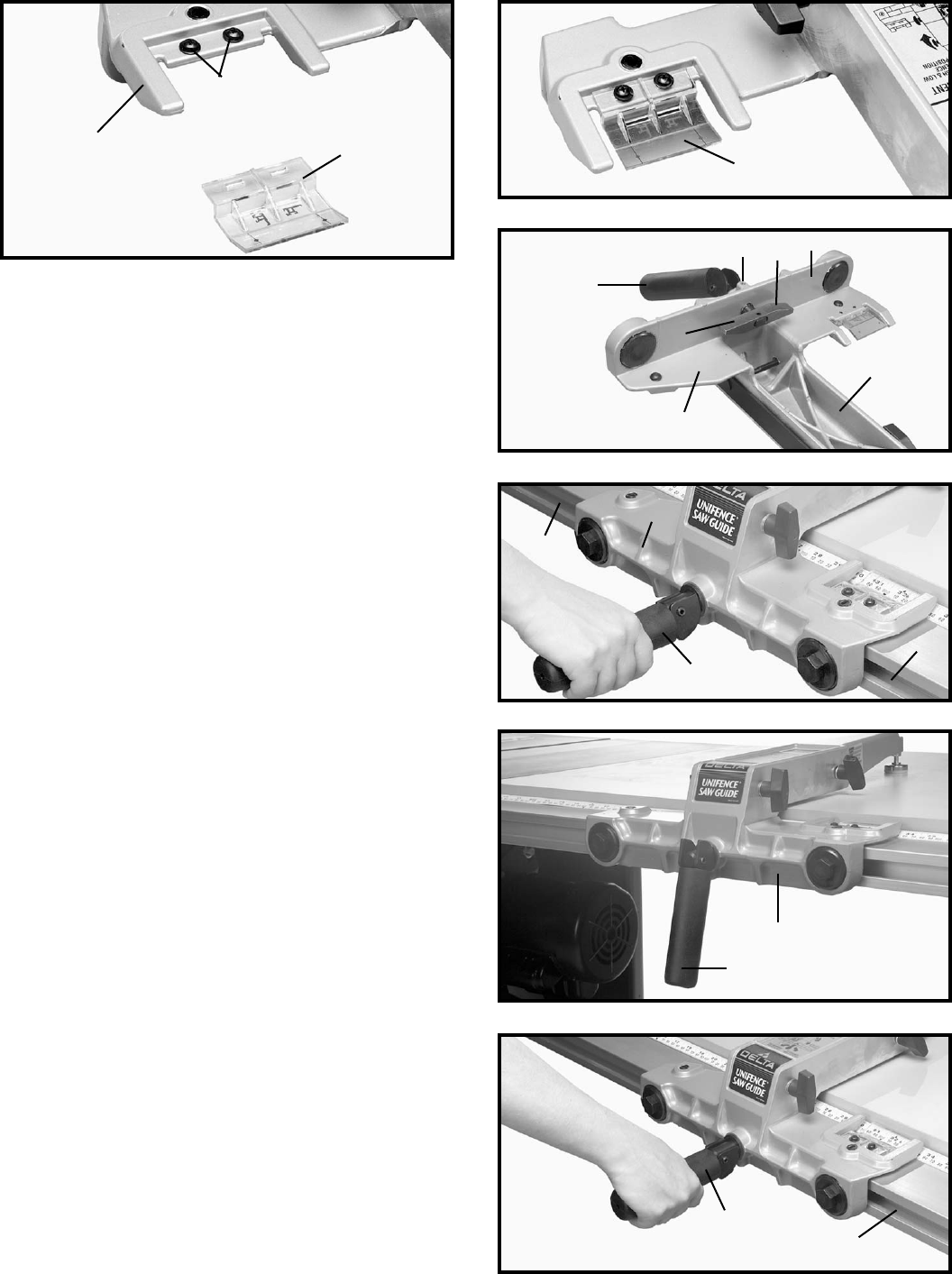

ASSEMBLING CURSOR TO

UNIFENCE BODY

1. Remove two screws and flat washers (A) Fig. 60, and

assemble the cursor (B) to the Unifence body (C).

Replace the two screws and flat washers (A).

2. Fig. 61 illustrates the cursor (B) assembled to the

Unifence body. Adjustment to the cursor (B) will be made

later.

Fig. 60

Fig. 61

A

C

B

B

Fig. 62

Fig. 63

Fig. 64

B

C

E

F

D

A

B

G

G

B

G

Fig. 65

A

B

ASSEMBLING UNIFENCE

BODY TO GUIDE RAIL

1. Turn fence body (A) Fig. 62, upside down and lay it on

a table or bench. Rotate the handle (B) to the left till it

stops in the positive indent. The clamp bracket (C) should

be parallel to surface (D) of the fence body. Pull the

handle (B) out till the clamp bracket (C) contacts surface

(F) of the fence body. If necessary pivot the clamp bracket

till it is parallel to surface (F). Push the handle (B) back in,

but do not rotate it.

2. Place fence body (A) Fig. 63, onto the guide rail as

shown, making sure clamp bracket is inserted into

channel (G) on rail. Notice that the clamp handle (B) is

turned to the left indent position.

3. Make sure the handle (B) Fig. 64, is pushed in, then

rotate the handle to the right to the positive indent. This

will position the clamp bracket in the locking position,

and prevent the fence clamp from sliding out of the

channel (G).

4. Lock fence body (A) to the guide rail by pushing

down on handle (B) as shown in Fig. 65.

A

ADJUSTING CLAMP

HANDLE POSITIVE INDENTS

1. If the clamp handle is to tight or to loose when

rotating to the left positive indent for fence removal, or to

the right positive indent for fence locking and adjustment

can be made.

2. Turn the fence body (A) Fig. 62, upside down and lay

it on a table or bench. To make the indents feel more

positive tighten the set screw (G), to make the indents

less positive loosen the set screw (G).

G