31

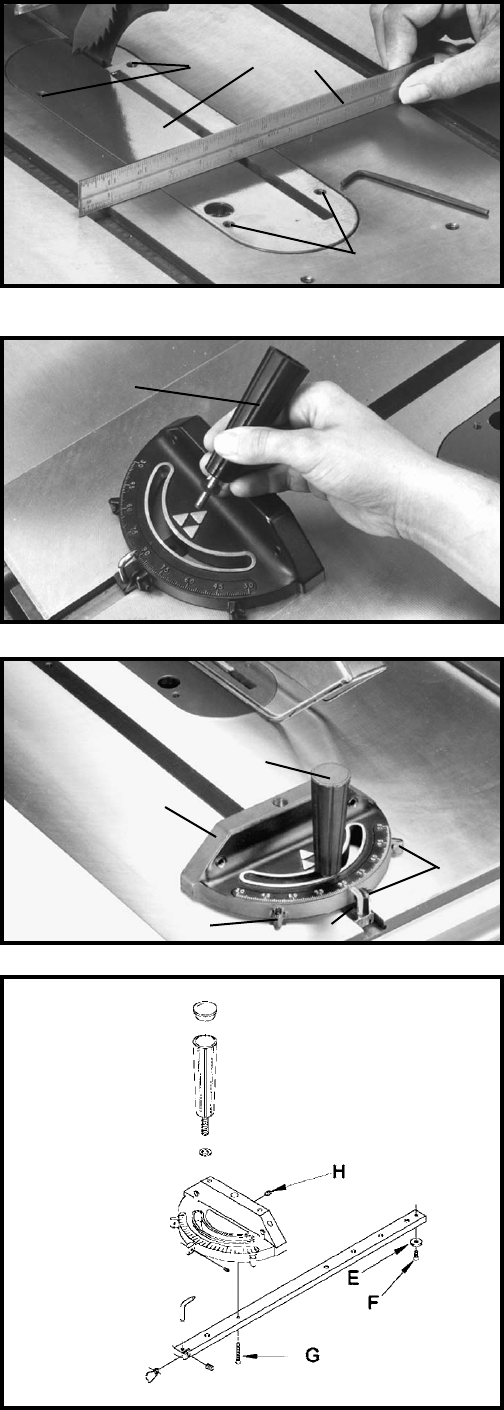

ADJUSTING TABLE INSERT

Place a straight edge (B) across the table at both ends of

the table insert as shown in Fig. 113. The table insert (A)

should always be level with the table. If an adjustment is

necessary, turn the adjusting screws (C), as needed, with

allen wrench supplied. NOTE: THE MITER GAGE

HANDLE CAN BE USED TO STORE THE ALLEN

WRENCHES WHEN NOT IN USE. REMOVE THE TOP

CAP OF THE MITER GAGE HANDLE FOR THE ALLEN

WRENCH STORAGE COMPARTMENT.

Fig. 113

B

A

C

C

MITER GAGE OPERATION

AND ADJUSTMENT

Insert the miter gage bar into the miter gage slot and

assemble the washer and lock handle (A) Fig. 114, to the

miter gage bar as shown.

The miter gage is equipped with adjustable index stops at

90 degrees and 45 degrees right and left. Adjustment to

the index stops can be made by tightening or loosening

the three adjusting screws (B) Fig. 115, with allen wrench

supplied.

To rotate the miter gage, loosen lock knob (A) Fig. 115,

and move the body of the miter gage (C), to the desired

angle.

The miter gage body will stop at 90 degrees and 45

degrees both right and left. To rotate the miter gage body

past these points, the stop link (D) Fig. 115, must be

moved up and out of the way.

The head of the miter gage pivots on a special tapered

screw (G) that fastens the head to the miter gage bar. If

the miter gage head does not pivot freely, or pivots too

freely, it can be adjusted by loosening set screw (H) Fig.

116, and turning the screw (G) in or out. Be certain to

tighten screw (H) after adjustment is made.

Your miter gage is equipped with a plate (E) Fig. 116,

which fits into the T-Slot groove in the table. This allows

the miter gage to be pulled off the front edge of the table

without falling. This allows for a longer cut off capacity in

front of the blade.

Fig. 114

Fig. 115

Fig. 116

A

A

C

B

B

D