psi

bar

MPa

13308842

Pressure Control Repair

Digital Display Messages

1. Lift lid on pressure control cover and view display.

2. Observe display and reference following table:

3.

No display does not mean

that sprayer is not pressur-

ized. Relieve pressure before repairing;

page 3.

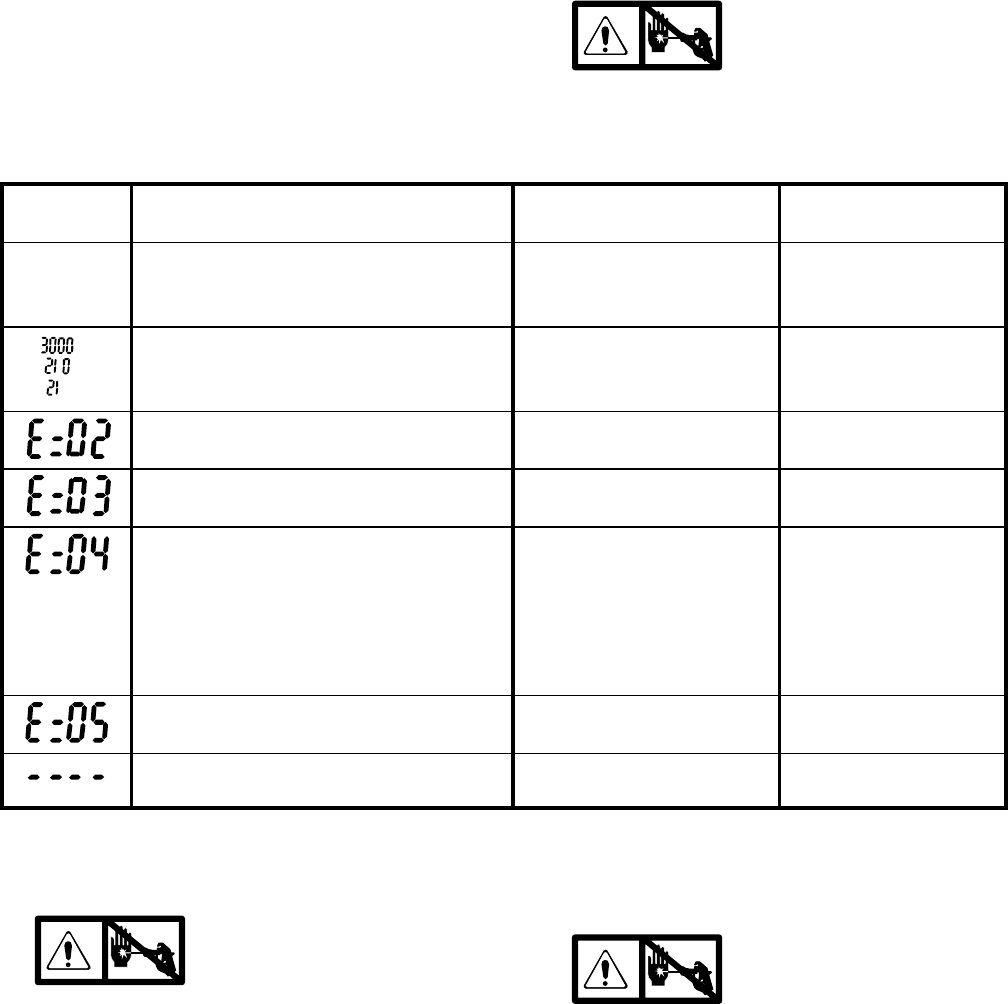

DISPLAY SPRAYER

OPERATION

INDICATION ACTION

No Display Sprayer stops. Power is not applied.

Sprayer may be pressurized.

Loss of power Check power source

Sprayer is pressurized. Power is applied.

(Pressure varies with tip size and pres-

sure control setting.)

Normal operation Spray

Sprayer stops. Power is applied. Pressure greater than

4500 psi (310 bar, 31 MPa).

Replace pressure

control board

Sprayer stops. Power is applied. Pressure transducer faulty Replace

Sprayer stops. Power is applied. Line voltage too high Set voltage to:

230 VAC for models

232144, 145, 154

110 VAC for models

232148, 158

100 VAC for models

232156, 157

Sprayer stops. Power is applied. Locked rotor. Motor can not

turn

Repair or replace

Sprayer stops. Power is applied. Pressure less than

200 psi (14 bar, 1.4 MPa)

Increase pressure

Pressure Control Transducer

Removal

1.

Relieve pressure; page 3.

2. Fig. 7. Remove five screws (28) and cover (82).

3. Disconnect lead (E) from motor control

board (104).

4. Remove strain relief bushing (116).

5. Remove pressure control transducer (31) and

packing o-ring (59) from control housing plate (89).

Installation

1. Fig. 7. Install packing o-ring (59) and pressure

control transducer (31) in control housing

plate (89). Torque to 30–35 ft-lb.

2. Install strain relief bushing (116).

3. Connect lead (E) to motor control board (104).

4. Install cover (82) with five screws (28).

Pressure Adjust Potentiometer

Removal

1.

Relieve pressure; page 3.

2. Fig. 7. Remove five screws (28) and cover (82).

3. Disconnect lead (D) from motor control

board (104).

4. Remove potentiometer knob (81), sealing shaft nut

(106) and pressure adjust potentiometer (105).

Installation

1. Fig. 7. Install pressure adjust potentiometer (105),

sealing shaft nut (106) and potentiometer knob

(81).

2. Connect lead (D) to motor control board (104).

3. Install cover (82) with five screws (28).