15308842

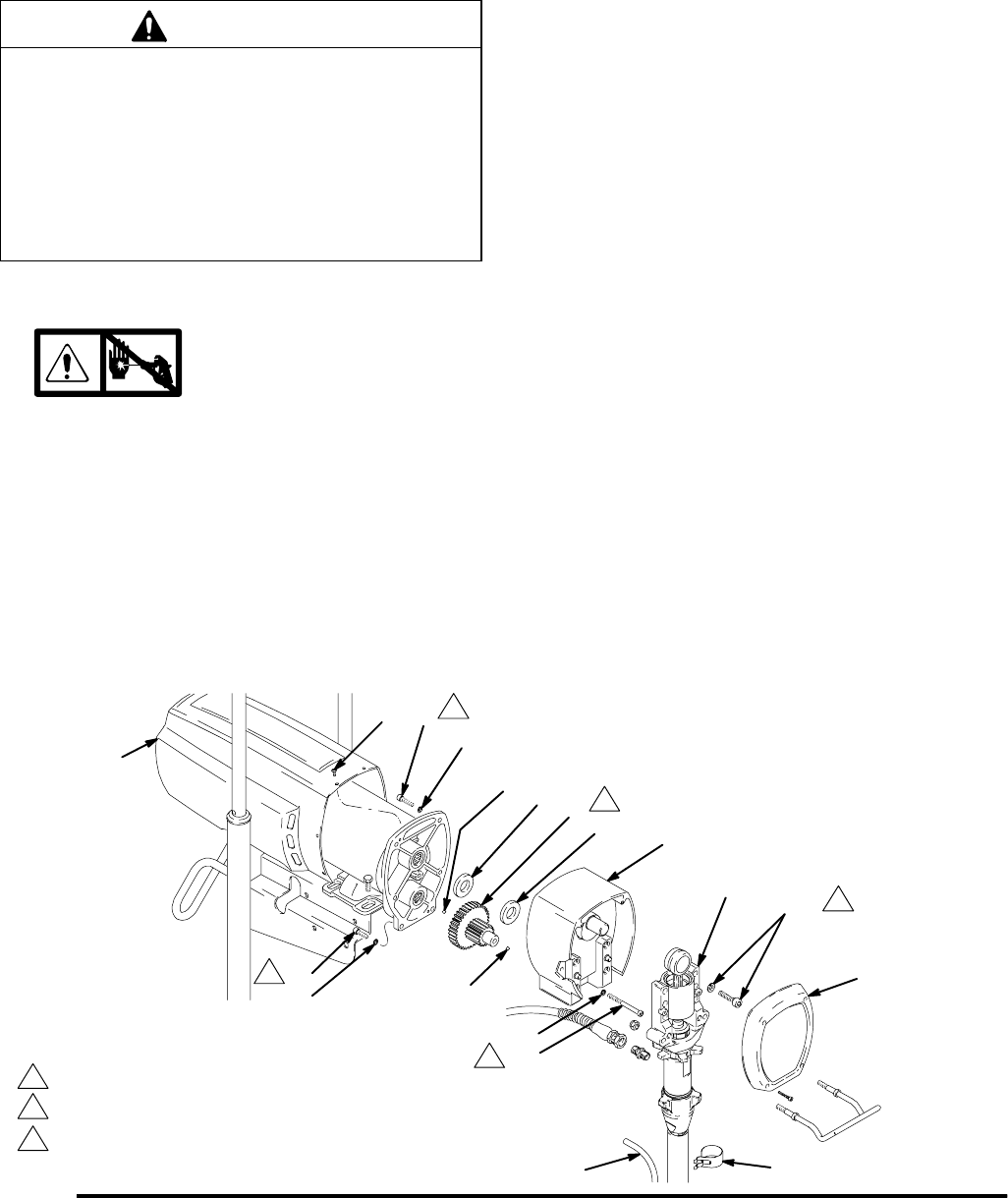

Drive Housing Replacement

CAUTION

Do not drop gear cluster (51) when removing drive

housing (67). Gear cluster may stay engaged in

motor front end bell or drive housing.

Do not lose thrust balls (90) or drop thrust balls

between gears. If thrust balls are caught between

gears and not removed, serious damage will occur to

drive housing. If thrust balls are not in place at each

end of gear cluster, bearings will wear prematurely.

1. Read General Repair Information on page 3.

2.

Relieve pressure; page 3.

3. Fig. 9. Remove front cover (49) and motor shield

(54). Unclip drain hose (85) from pump.

4. Remove four bearing housing screws (25) and

lockwashers (23).

5. Tap lower rear of bearing housing (22) with plastic

mallet to loosen from drive housing (67). Pull

bearing housing and connecting rod straight off

drive housing.

6. Remove two drive housing screws (26) and

lockwashers (20).

7. Remove two lower screws (16) and lockwashers

(20) and then two upper screws (16) and lock-

washers (20) from front of motor (73).

8. Tap drive housing (67) with plastic mallet to loosen

from front of motor (73); pull drive housing straight

off.

9. Apply approximately 4 oz of bearing grease to

gear cluster (51). Grease is supplied with drive

housing replacement kit. Be sure thrust balls (90)

are in place.

10. Place bronze-colored washer (67b) then silver-col-

ored washer (67a) on shaft protruding from big

gear in drive housing (67).

11. Align gears and push new drive housing straight

onto front of motor and locating pins.

12. Continue reassembling sprayer.

Fig. 9

16

20

49

67

67b

51

67a

90

90

34

26

20

54

22

20

16

25, 23

85

7699B

Torque to 175 in-lb (19 Nm)

3

2

Torque to 90–100 in-lb (10.2–11.3 Nm)

Liberally apply grease

1

1

2

2

2

3

36