9308842

Spin Test

Setup

Electric Shock Hazard; page 3.

To check armature, motor winding and brush electrical

continuity:

1.

Relieve pressure; page 3.

2. Remove drive housing; page 15.

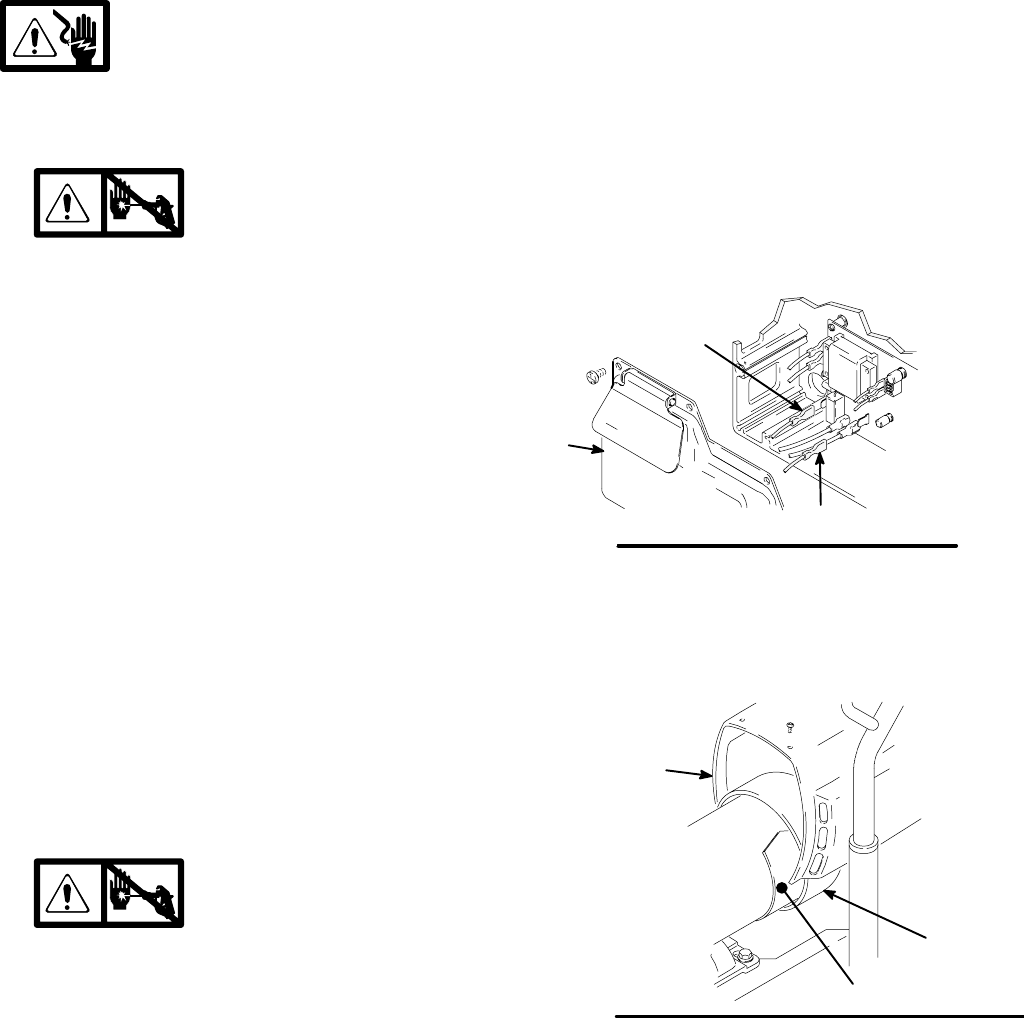

3. Fig. 3. Remove pressure control cover (82). Dis-

connect motor leads (F) and (G).

4. Fig. 4. Remove motor shield (54), fan cover (A)

and inspection covers (B).

Armature Short Circuit Test

Quickly turn motor fan by hand. If no electrical shorts,

motor coasts two or three revolutions before complete

stop. If motor does not spin freely, armature is

shorted. Replace motor; page 16.

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

1. Connect red and black motor leads together with

test lead. Turn motor fan by hand at about two

revolutions per second.

2. If uneven or no resistance, check for: broken brush

springs, brush leads, motor leads; loose brush

terminal screws, motor lead terminals; worn

brushes. Repair as needed; page 9.

3. If still uneven or no resistance, replace motor;

page 16.

Fig. 3

G

82

F

8051A

Motor Brush Replacement

NOTE: Replace brushes worn to less than 1/2 in.

Brushes wear differently on each side of motor,

check both sides. Brush Repair Kit 220853 is

available. Spring clip, 110816, may be

purchased separately.

Motor Brush Removal

1. Read General Repair Information; page 3.

2.

Relieve pressure; page 3.

3. Fig. 4. Remove motor shield (54). Remove in-

spection covers (B) and gaskets on each side of

motor.

(Continued on page 10)

A

B

54

Fig. 4

7703B