Maintenance

312666R 27

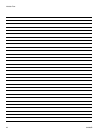

Clean Fluid Manifold

Clean fluid manifold fluid ports with compatible

solvent and brush whenever removed from

gun. Do not damage the internal sealing sur-

faces. Fill fluid ports with grease if left

exposed, to seal out moisture.

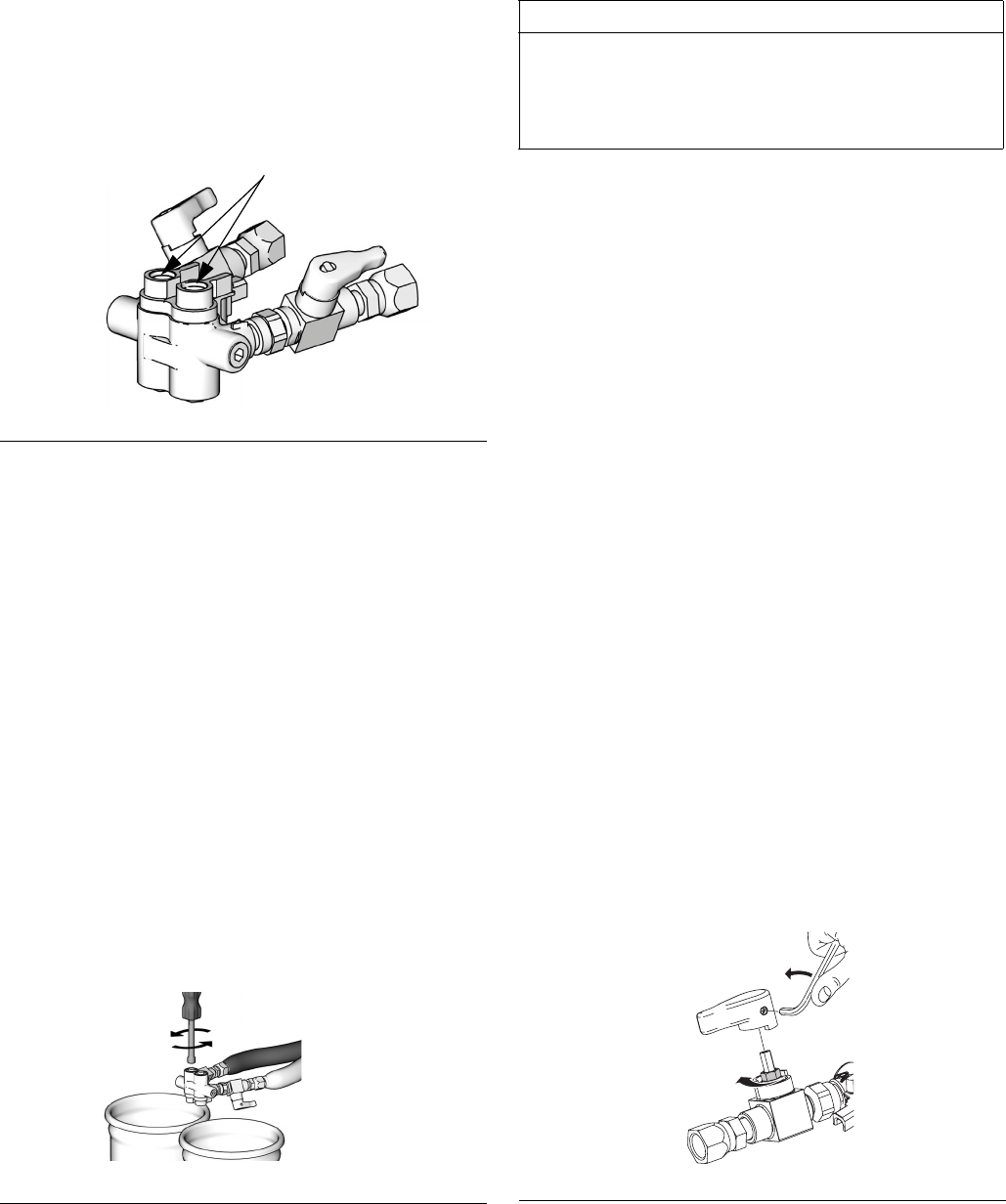

Clean or Replace Fluid Screens

1. Follow Pressure Relief Procedure, page

17.

2. Relieve pressure in hose manifold after gun

is removed.

a. Place the fluid manifold over containers,

facing away from you.

b. Ensure fluid valves are closed.

c. Very slowly open fluid manifold check

valves 2 to 2-1/2 turn. Under high pres-

sure, fluid will spray sideways from the

fluid ports.

3. Remove fluid screens by unthreading them

from fluid manifold.

4. Clean or replace fluid screens. See Acces-

sories, page 55.

5. Carefully inspect o-rings and fluid screen

surfaces. Replace if worn or damaged.

6. Liberally lubricate o-rings and reassemble.

Use a hex nut driver to tighten.

Adjust Fluid Valve Packings

Periodic adjustment may be necessary to stop

fluid leakage. If fluid valve is leaking, adjust the

packings:

1. Follow Pressure Relief Procedure, page

17.

2. Loosen set screw and remove valve han-

dle.

3. Turn valve packing nut clockwise in

1/8-turn increments until leak is corrected.

4. Re-pressurize system then check for leaks.

Repeat procedure as necessary.

F

IG

. 36:

F

IG

. 37

Fluid Ports

TI12089a

TI11337a

CAUTION

To prevent cross-contamination of the check

valves, do not interchange A component and

B component parts. The A component check

valve is marked with an A.

F

IG

. 38

1/8

TI19008a