Troubleshooting

312666R 31

Troubleshooting

1. Follow Pressure Relief Procedure, page

17, before checking or repairing gun.

2. Check all possible problems and causes

before disassembling gun.

CAUTION

To prevent cross-contamination of gun’s wet-

ted parts, do not interchange A component

(isocyanate) and B component (resin) parts.

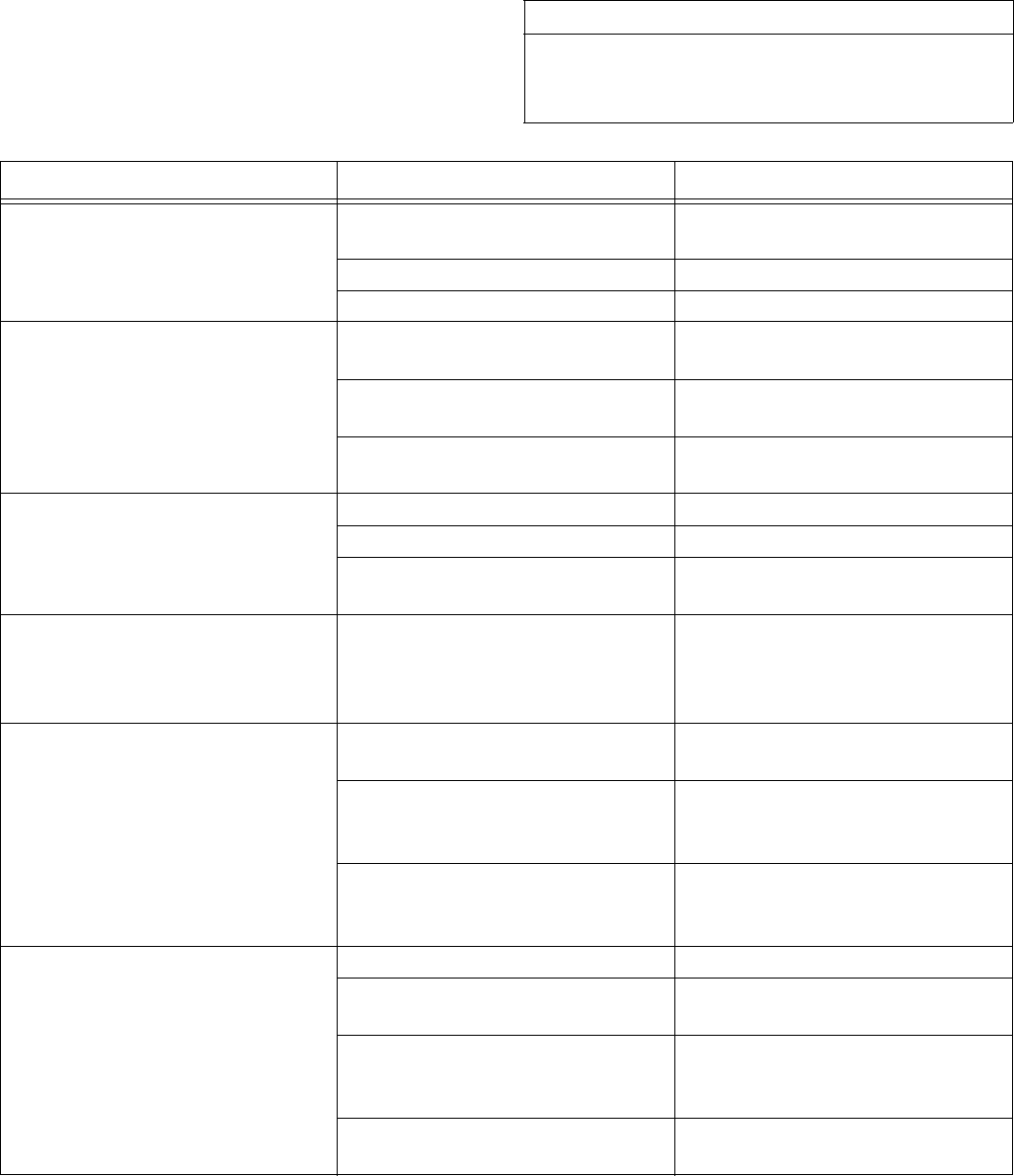

PROBLEM CAUSE SOLUTION

Gun does not fully actuate when

triggered.

Safety lock engaged. Disengage piston safety lock. See

Piston Safety Lock, page 12.

Plugged breather plug (9). Clean Breather Plug, page 26.

Damaged air valve o-rings (15). Replace. See Air Valve, page 43.

Fluid does not spray when gun is

fully actuated.

Closed fluid valves (1b). Open.

Plugged impingement ports. Clean Impingement Ports, page

29.

Plugged check valves (44,45). Clean. See Check Valves, page

41.

Gun actuates slowly. Plugged breather plug (9). Clean Breather Plug, page 26.

Damaged piston o-rings (4a, 4c). Replace. See Piston, page 42.

Dirty air valve, or damaged

o-rings (15).

Clean air valve or replace o-rings.

See Air Valve, page 43.

Gun delays, then actuates

abruptly.

Cured material around side seals

(42, 43).

Inspect side seals (42c) and mix

chamber (14) for scratches.

Replace; see Mix Chamber and

Side Seal Assemblies, page 38.

Loss of round pattern. Dirty mix chamber (14) nozzle. Clean Mix Chamber Nozzle,

page 28.

Empty ClearShot Liquid cartridge. Replace. See ClearShot Liquid

Cartridge Installation/Removal ,

page 23.

ClearShot Liquid dosing pump is

not primed.

Prime dosing pump. See Clear-

Shot Liquid Cartridge Installa-

tion/Removal , page 23.

Loss of flat pattern. Plugged spray tip. Clean in compatible solvent.

Worn tip. Replace. See Flat Spray Tips,

page 19.

Empty ClearShot Liquid cartridge. Replace. See ClearShot Liquid

Cartridge Installation/Removal ,

page 23.

Dirty mix chamber (14) nozzle. Clean Mix Chamber Nozzle,

page 28.