Operation

Flush the Gun Daily

WARNING

Dressure Relief Procedure

To reduce the risk of serious injury, including fluid

njection, splashing in the eyes or on skin, or injury

‘ram moving parts, always follow this procedure

Nhenever the pump is shut off, when checking or

servicing any part of the system, when installing or

:hanging spray tips and whenever you stop

spraying.

1.

2.

3.

4.

5.

6.

7.

8.

Engage the spray gun safety latch.

Shut off the power to the pump.

Close the bleed-type master air valve

(required in system).

Disengage the gun safety latch.

Hold a metal part of the gun firmly to the side

of a grounded metal waste container and trig-

ger the gun to relieve fluid pressure.

Engage the gun safety latch again.

Open the pump drain valve (required in sys-

tem) to help relieve fluid pressure in the dis-

placement pump. In addition, open the drain

valve connected to the fluid pressure gauge

(in a system with fluid regulation) to help

relieve fluid pressure in the hose and gun.

Triggering the gun to relieve pressure may not

be sufficient. Have a container ready to catch

the drainage.

Leave the drain valve(s) open until you are

ready to spray again.

If you suspect that the spray tip or hose is com-

pletely clogged or that pressure has not been fully

relieved after following the steps above, very slow-

ly loosen the hose end coupling and relieve pres-

sure gradually, then loosen completely. Now clear

the tip or hose obstruction.

1. Follow the Pressure Relief Procedure Warning,

above.

2. Disconnect the atomizing air hose and the fluid

supply line.

3. Remove the spray tip.

4. Connect the solvent supply to the gun.

CAUTION

Be sure the solvent is compatible with the fluid

being sprayed to avoid clogging the gun’s fluid

passages.

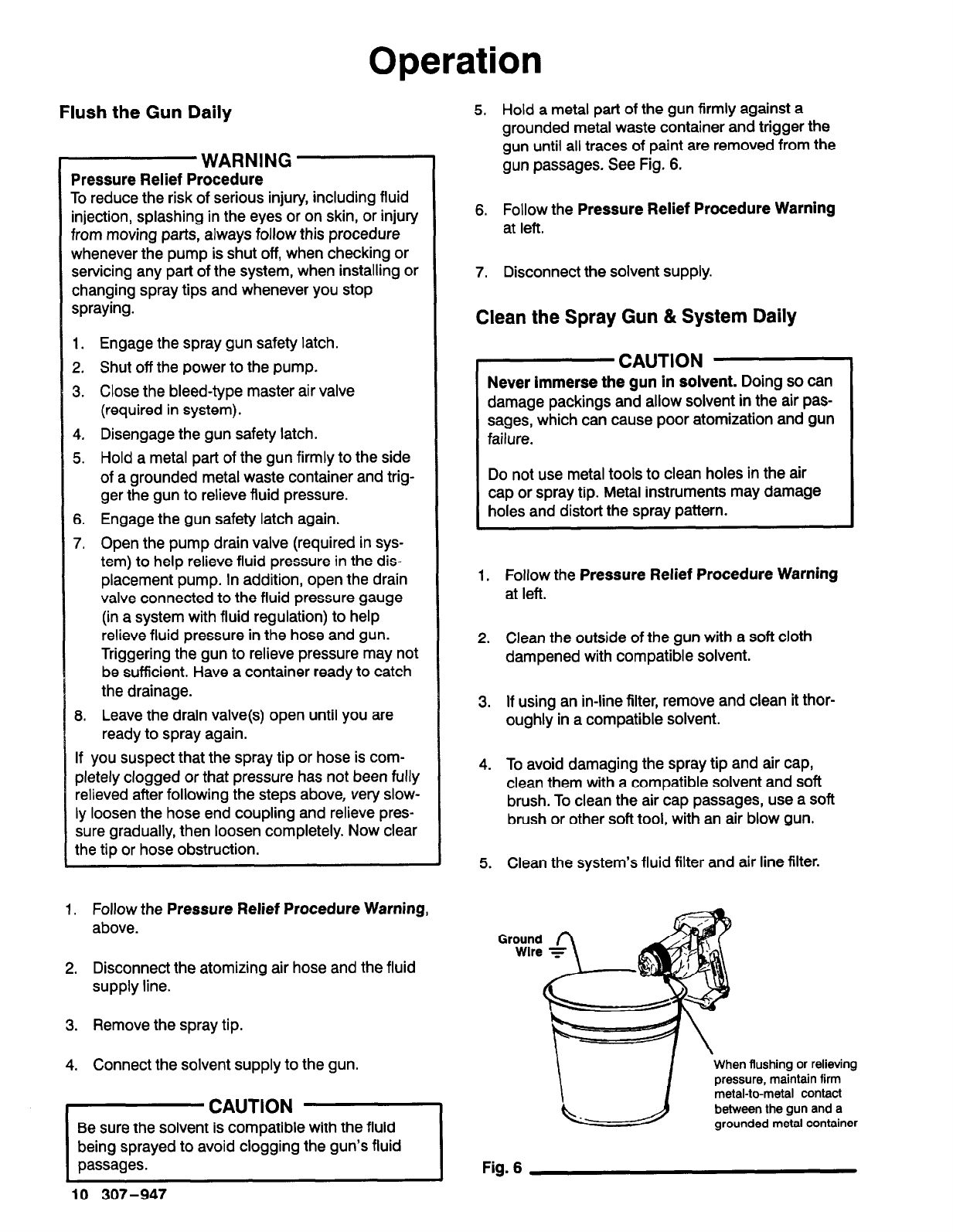

5. Hold a metal part of the gun firmly against a

grounded metal waste container and trigger the

gun until all traces of paint are removed from the

gun passages. See Fig. 6.

6. Follow the Pressure Relief Procedure Warning

at left.

7. Disconnect the solvent supply.

Clean the Spray Gun & System Daily

CAUTION

Never immerse the gun in solvent. Doing so can

damage packings and

allow solvent in the air pas-

sages, which can cause poor atomization and gun

Do not use metal tools to clean holes in the air

cap or spray tip. Metal instruments may damage

holes and distort the spray pattern.

1. Follow the Pressure Relief Procedure Warning

at left.

2. Clean the outside of the gun with a soft cloth

dampened with compatible solvent.

3. If using an in-line filter, remove and clean it thor-

oughly in a compatible solvent.

4. To avoid damaging the spray tip and air cap,

clean them with a compatible solvent and soft

brush. To clean the air cap passages, use a soft

brush or other soft tool, with an air blow gun.

5. Clean the system’s fluid filter and air line filter.

Ground

Wire

When flushing or relieving

pressure, maintain firm

metal-to-metal contact

between the gun and a

grounded metal container

Fig. 6

10 307-947