Operation

Select a Spray Tip

Use the Spray Tip Selection charts on page 18, as a

guide for selecting an appropriate spray tip for your

application. The fluid output and pattern width

depend on the size of the spray tip, the fluid viscosity,

and the fluid pressure.

NOTE: When spraying very low viscosity fluids, use

the optional fluid needle 220-413 (see page 15). The

standard needle may not provide positive shut off for

such fluids.

Install a Spray Tip

To reduce the risk of a fluid injection injury, Always

before removing or installing a spray tip.

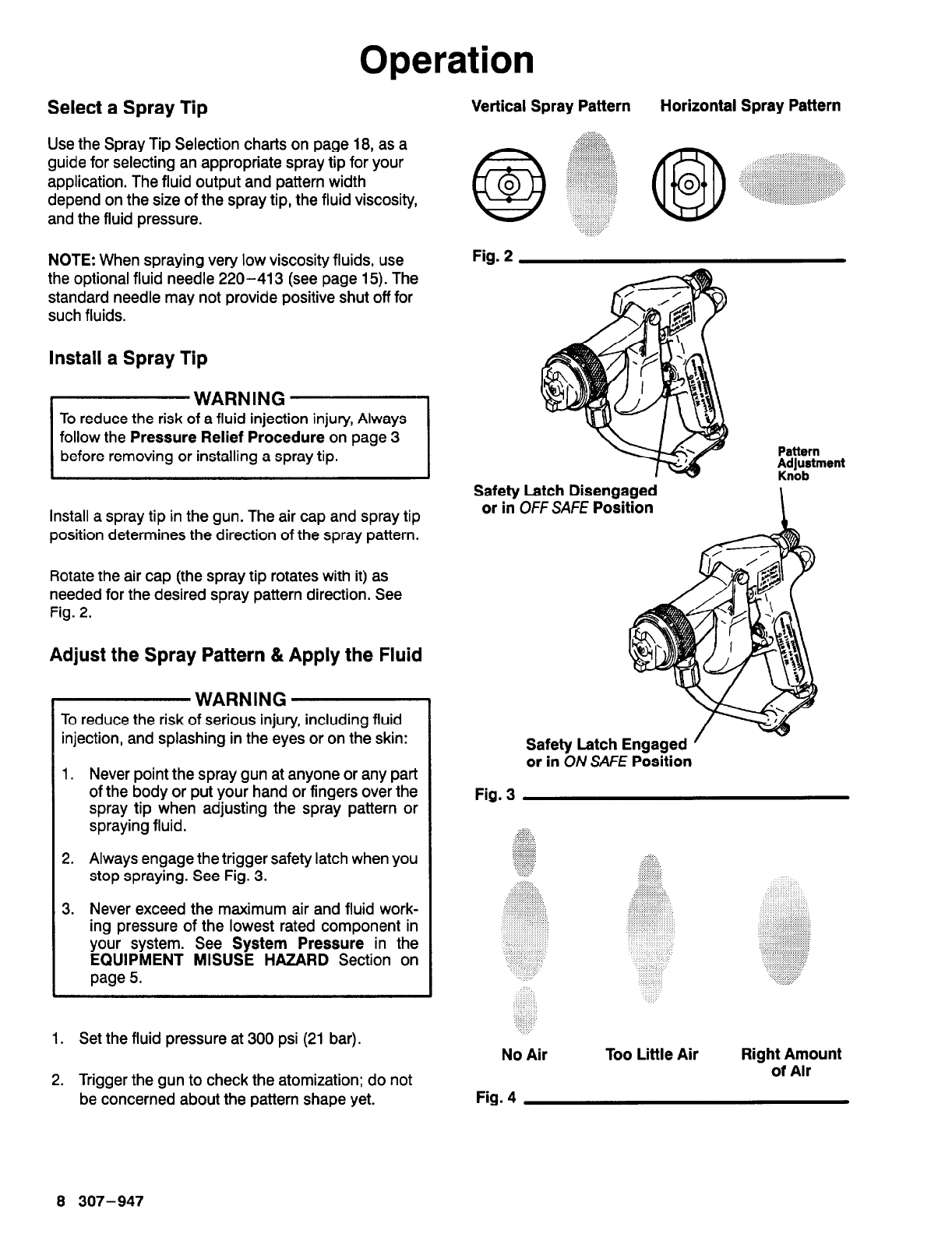

Install a spray tip in the gun. The air cap and spray tip

position determines the direction of the spray pattern.

Rotate the air cap (the spray tip rotates with it) as

needed for the desired spray pattern direction. See

Fig. 2.

Adjust the Spray Pattern & Apply the Fluid

WARNING

To reduce the risk of serious injury, including fluid

injection, and splashing in the eyes or on the skin:

1. Never point the spray gun at anyone or any part

of the body or put your hand or fingers over the

spray tip when adjusting the spray pattern or

spraying fluid.

2. Always engage the trigger safety latch when you

stop spraying. See Fig. 3.

3. Never exceed the maximum air and fluid work-

ing pressure of the lowest rated component in

your system. See System Pressure in the

EQUIPMENT MISUSE HAZARD Section on

page 5.

1. Set the fluid pressure at 300 psi (21 bar).

2. Trigger the gun to check the atomization: do not

be concerned about the pattern shape yet.

Vertical Spray Pattern

Horizontal Spray Pattern

Pattern

ki~gtment

Safety Latch Disengaged

or in

OFF SAFE

Position

Safety Latch Engaged

or in

ON SAFE

Position

::$2

; ,: .,,.

. . . . . .::: .:;ri:

:..I

. .

,.:.,

i

. . . . .

No Air

Too Little Air

Right Amount

of Air

8

307-947