Installation

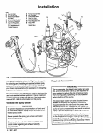

Connect the Air Line

Install an air line filter (H) to ensure a clean, dry air

supply to the gun. Dirt and moisture in the line can

ruin the appearance of your finished piece.

Install Air Pressure Regulator 1 lo-776 (F) to control

the air pressure to the gun and limit it to 10 psi (0.7

bar)

Maximum Operating Air Pressure.

Install a bleed-type master air valve (C) on the main

air line. Install a bleed-type master air valve or air

pressure relief valve (P), which is easily accessible

from the pump and downstream from the pump air

regulator (E).

NOTE: The gun air inlet has a l/4-1 8 npsm

@1/4-l 9) compound male thread that is compatible

with NPSM and BSP female swivel connectors.

Connect the air hose (K) from the air supply to the

gun air inlet.

Connect the Fluid Line

Install a fluid pressure regulator (M) to control fluid

pressure to the gun. Some applications require

fine-tuned control of fluid pressure. You can control

fluid pressure more accurately with a fluid pressure

regulator than by regulating the air pressure to the

w-v.

Install fluid drain valve(s) (J) to help relieve fluid

pressure.

NOTE: The gun fluid connector (6) has a l/4-18

npsm (Rl/4- 19) compound male thread that is com-

patible with NPSM and BSP female connectors.

Install an in-line fluid filter (see part no. 210-500 in

the Accessories section) on the gun fluid connector

(B) to avoid clogging the spray tip with particles from

your fluid.

Connect the grounded fluid hose (L) to the gun fluid

connector (B) or optional in-line filter.

Grounding

WARNING

To reduce the risk of serious injury, be sure your

entire system is properly grounded. Read FIRE

AND EXPLOSION HAZARD on page 4. The gun

is grounded by connecting it to a properly

grounded pump and hose.

Operation

WARNING

The wallet sized warning card 179-960, provided

with the gun, should be available and easily

accessible at all times for anyone operating or

servicing this equipment. The card contains

important information on what to do if a fluid injec-

tion injury occurs. Additional cards are available at

no charge from Grace.

I

1

How the Air-Assisted Airless

Spray Gun Operates

The spray gun has a built-in lead and lag operation.

When triggered, the gun begins emitting air before

the fluid is discharged. When the trigger is released,

the fluid stops before the air flow stops. This helps

assure the spray is atomized and prevents fluid

buildup on the air cap.

Note that the air-assisted airless spray gun differs

from an air spray gun in that increasing the pattern air

reduces the pattern width. To increase the pattern

width, less pattern air or a larger size tip must be

used.

The air-assisted airless gun combines airless and air

spraying concepts. The spray tip shapes the fluid into

a fan pattern, similar to a conventional airless spray

tip, but at a lower pressure. Air from the air cap fur-

ther atomizes the fluid and completes the atomization

of the paint tails into the pattern. The pattern adjust-

ment valve controls the width of the pattern.

Remember, this is not an air spray gun; for your

safety be sure to read and follow the Warnings on

pages 3 to 5 and throughout the text of thus

307-947 7