Operation

Adjust the Spray Pattern & Apply

the Fluid

(Continued’

1. Increase the fluid pressure just to the point where

a further increase in fluid pressure does not sig-

nificantly improve fluid atomization. Do not exceed

950 psi (66 bar) fluid pressure to the gun.

2. Close the pattern adjustment valve by turning the

knob (see Fig. 3) counterclockwise all the way.

This sets the gun for its widest pattern

3. Set the atomizing air pressure at about 5 psi (0.35

bar). Check the spray pattern, then adjust the air

pressure until all the tails are completely atomized

and pulled into the spray pattern. See Fig. 4.

NOTE: Do not exceed 10 psi (0.7 bar) air pressure to

the gun. The air cap supplied with this gun was

designed to operate at or below 10 psi (0.7 bar) air

pressure to comply with California Wood Rule 1136.

For

a narrower pattern, turn the pattern adjust-

ment valve knob clockwise. If the pattern is still

not narrow enough, increase the air pressure to

the gun slightly or use a different size tip.

NOTE: For some spray tips, when the line air pres-

sure to the gun is increased to a certain level, the

spray pattern will become round. This is the smallest

pattern width. Further increases in air pressure will

force the pattern to turn from horizontal to vertical or

from vertical to horizontal.

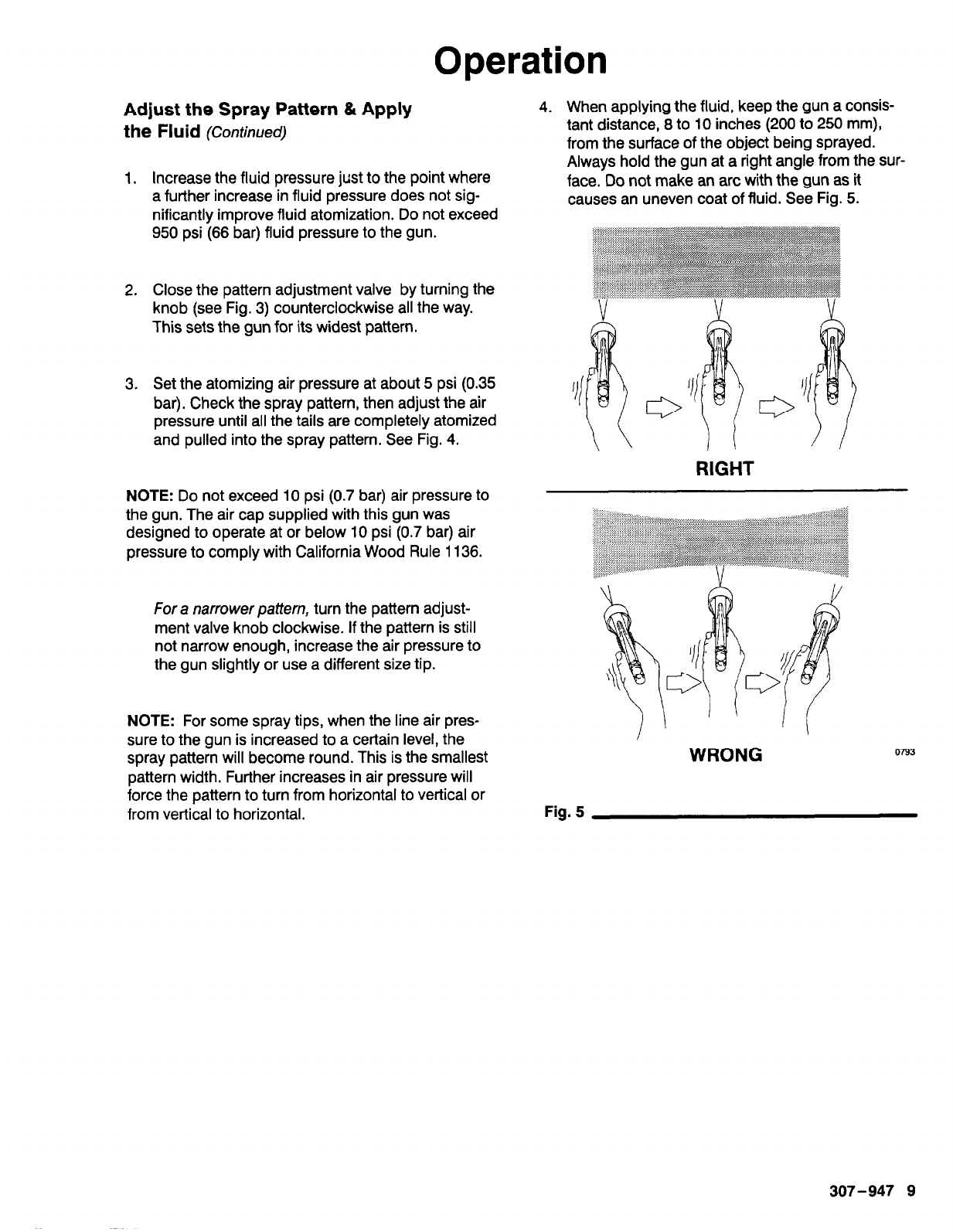

4. When applying the fluid, keep the gun a consis-

tant distance, 8 to 10 inches (200 to 250 mm),

from the surface of the object being sprayed.

Always hold the gun at a right angle from the sur-

face. Do not make an arc with the gun as it

causes an uneven coat of fluid. See Fig. 5.

RIGHT

WRONG

0793

307-947 9