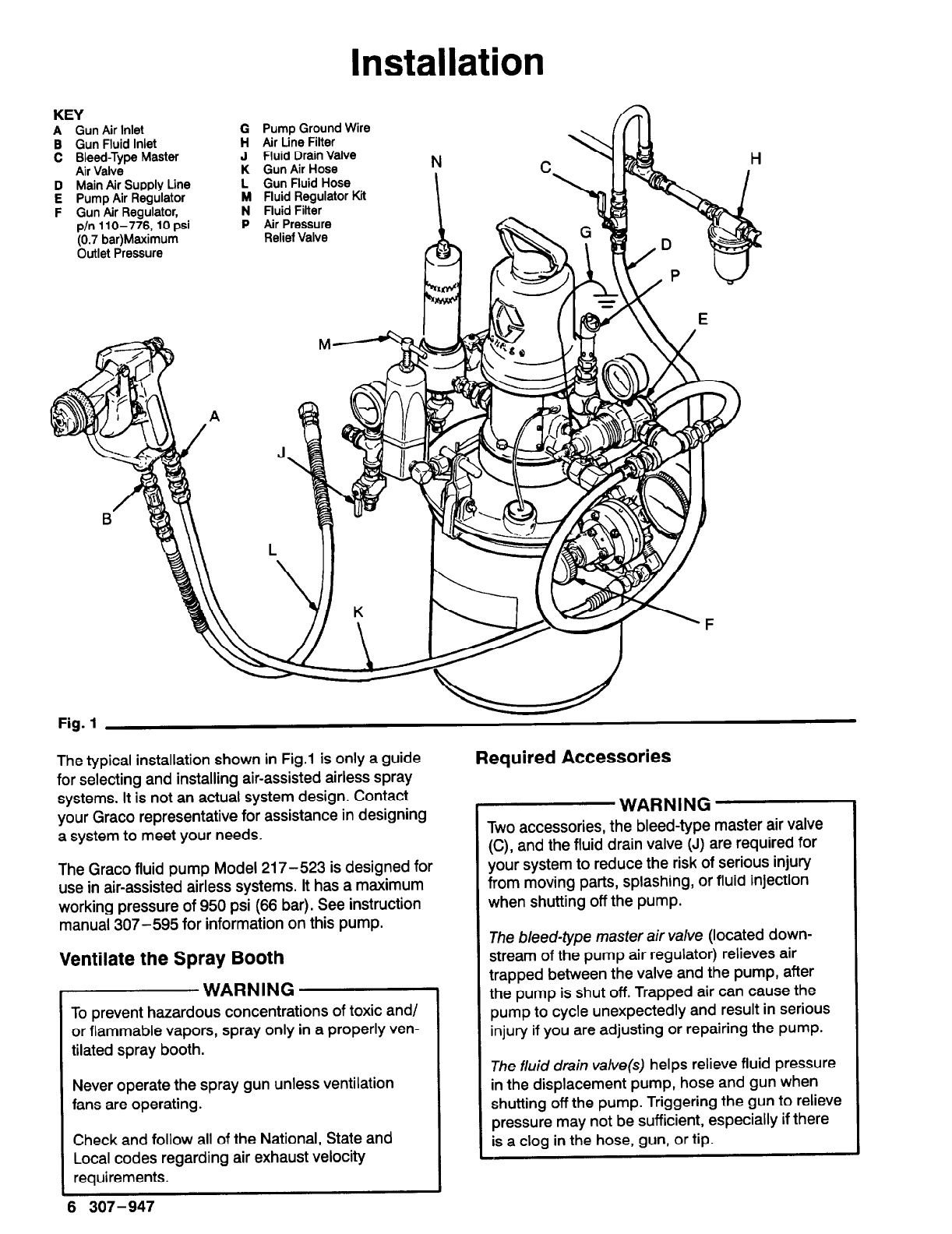

Installation

KEY

A Gun Air Inlet

B Gun Fluid Inlet

C Bleed-Type Master

Air Valve

D Main Air Supply Line

E Pump Air Regulator

F Gun Air Regulator,

p/n 110-776, 10 psi

(0.7 bar)Maximum

Outlet Pressure

G Pump Ground Wire

H Air Line Filter

J Fluid Drain Valve

K Gun Air Hose

L Gun Fluid Hose

M Fluid Regulator Kit

N Fluid Filter

P Air Pressure

Relief Valve

Fig. 1

The

typical installation shown

in

Fig.1

is only a guide

for selecting and installing air-assisted airless spray

systems. It is not an actual system design. Contact

your Grace representative for assistance in designing

a system to meet your needs.

The Grace fluid pump Model 217-523 is designed for

use in air-assisted airless systems. It has a maximum

working pressure of 950 psi (66 bar). See instruction

manual 307-595 for information on this pump.

Ventilate the Spray Booth

WARNING

To prevent hazardous concentrations

of

toxic and/

or flammable vapors, spray only in a properly ven-

tilated spray booth.

Never operate the spray gun unless ventilation

fans are operating.

Check and follow all of the National, State and

Local codes regarding air exhaust velocity

requirements.

6 307-947

Required Accessories

WARNING

Two accessories, the bleed-type master air valve

(C), and the fluid drain valve (J) are required for

your system to reduce the risk of serious injury

from moving parts, splashing, or fluid injection

when shutting off the pump.

The

bleed-type master air valve

(located down-

stream of the pump air regulator) relieves air

trapped between the valve and the pump, after

the pump is shut off. Trapped air can cause the

pump to cycle unexpectedly

and result in serious

injury if you are adjusting or repairing the pump.

The fluid drain

valve(s) helps relieve fluid pressure

in the displacement pump, hose and gun when

shutting off the pump. Triggering the gun to relieve

pressure may not be sufficient, especially if there

is a clog in the hose, gun, or tip.