Repair

ReplaceReplace

Replace

SolenoidSolenoid

Solenoid

ValveValve

Valve

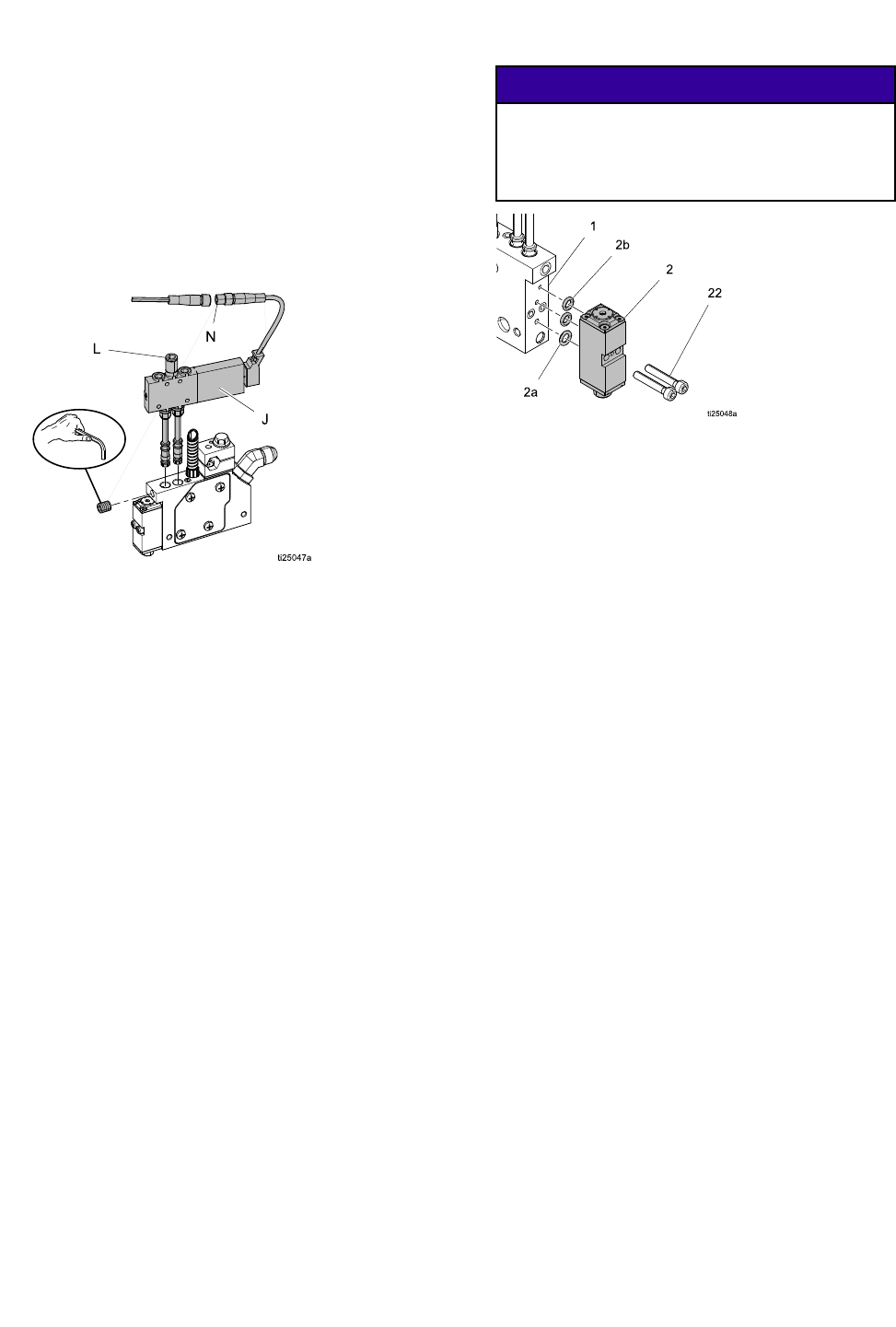

1. Disable the applicator. See

Before Beginning Repair, page 20.

2. Turn off the air supply to the solenoid valve.

3. Disconnect the M8 solenoid electrical connector

(N).

4. Disconnect air line from air tting (L).

Figure 15 Replace Solenoid Valve

5. Loosen the solenoid valve set screw with a 3 mm

Allen wrench, then remove the solenoid valve (J).

6. Apply high temperature grease to o-rings on

solenoid tubes.

7. Install the new solenoid valve into the manifold,

then use a 3 mm Allen wrench to tighten the

solenoid valve set screw.

8. Connect the M8 solenoid valve electrical

connector (N).

9. Connect the 1/4 in. air line to the solenoid. Turn

air on.

ReplaceReplace

Replace

ModuleModule

Module

1. Disable the applicator. See

Before Beginning Repair, page 20.

2. Use a 3 mm Allen wrench to remove the two

mounting screws (22) and module (2) from

manifold (1).

NOTICENOTICE

NOTICE

Do not allow adhesive to enter the air ports,

to allow air to ow through valve. Adhesive in

the air ports will obstruct the ow of air and

damage the valve.

Figure 16 Remove Module From Manifold

3. Verify that no glue is present in the manifold air

ports.

4. Apply high temperature lubricant to air section

o-rings (2b) and uid section o-ring (2a) in

module (2).

NOTE:NOTE:

NOTE:

Air section o-rings are brown and the

uid section o-ring is black. All o-rings are

uoroelastomer. The color is only used to identify

the difference in size.

5. Apply anti-seize to two screw threads (22). Use

a 3 mm Allen wrench to install new module (2) on

manifold with two screws (22). Torque to 28–32

in.-lb (3.2–3.6 N•m).

6. Connect cordset (17) to the heated hose.

ReplaceReplace

Replace

ApplicatorApplicator

Applicator

1. Disable the applicator. See

Before Beginning Repair, page 20.

2. Loosen the mounting bar clamp and remove the

applicator from the mounting bar.

3. Install new applicator. See Installation, page 9 .

24

334627D